binding wire 16 gauge

Latest articles

binding wire 16 gauge

...

binding wire 16 gauge 【binding wire 16 gauge】

Read Morebinding wire 16 gauge

...

binding wire 16 gauge 【binding wire 16 gauge】

Read Morebinding wire 16 gauge

...

binding wire 16 gauge 【binding wire 16 gauge】

Read Morebinding wire 16 gauge

...

binding wire 16 gauge 【binding wire 16 gauge】

Read MoreLarge rolls of galvanized wire products are widely used because of its anti-rust and anti-corrosion effect, because zinc has a great protective effect on the appearance of the product, so it greatly improves the role and characteristics of the product itself, which also promotes the promotion of the application of the product. The characteristics of galvanized wire products on galvanized wire products are the factors that determine many characteristics of galvanized wire products.

binding wire 16 gauge...

binding wire 16 gauge 【binding wire 16 gauge】

Read More

binding wire 16 gaugePVC coated barbed rope is widely used for railway highway protection, but also for safety protection of rivers, embankments and seawalls, so as to better protect the safety of people and animals.

...

binding wire 16 gauge 【binding wire 16 gauge】

Read More

binding wire 16 gaugeGalvanized hexagonal net is a kind of galvanized metal wire mesh, mesh shape is hexagonal.

...

binding wire 16 gauge 【binding wire 16 gauge】

Read More2. The cleaning agent used for cleaning should have no effect on the binding force of the coating and no corrosion on the matrix.

binding wire 16 gauge...

binding wire 16 gauge 【binding wire 16 gauge】

Read Morebinding wire 16 gauge

...

binding wire 16 gauge 【binding wire 16 gauge】

Read Morebinding wire 16 gauge

...

binding wire 16 gauge 【binding wire 16 gauge】

Read More

Popular articles

- Large hexagonal net is called stone cage net, mainly used for mountain protection, hydraulic construction, etc. Small wire hexagonal net is used as a good breeding material, the twisted flower hexagonal net in the welding of the iron frame get on the hexagonal net burning welding coops, pigeonholes, rabbit cages and other cage, hexagonal net is the best breeding material with the net.

- The mesh size of the wire mesh specification, as well as the diameter and thickness requirements, are limited to the amount of steel and galvanized per square meter. Mainly in order to consider the corrosion resistance, prolong the service life, and in the use of the process of safety.

- Decorative hook mesh welding, generally more robust, but assume that the workers are new, scheduling machine skills are not high, it will appear to open the solder joint. Once this situation is presented, it will bring significant losses to customers and factories.

Latest articles

-

-

3, some stainless steel pet cage on the market does not use 304 or higher material, the so-called 202, 201 stainless steel is easy to rust, please users in the purchase of stainless steel pet cage as far as possible not to choose.

-

-

The galvanizing process of galvanized wire products is a very effective metal anticorrosion method. It is also widely used in other industrial fields. The use of galvanized iron wire is very common in metal structure equipment of various industries. Due to the influence of production technology or other factors, the zinc layer of galvanized wire products will be different to a certain extent, especially ordinary galvanized can not reach the beauty of electric galvanized, the zinc layer of ordinary galvanized wire is mainly for corrosion prevention.

-

Traditional barbed wire is crisscross woven into the wire, with the development of the economy, the rapid rise of all walks of life, the limitations of the use of traditional barbed wire gradually exposed, such as: aquaculture, to the chicken circle cage can not be too dense, the wire can not be too thick, woven mesh wire once the mesh will become soft. We also have coping methods: 1, cotton gouging, rolling straight wire into wavy shape, but still not enough to raise chickens with mesh can only be extended to the beak can not feed! 2, is the electric welding net, with the current of the longitude and weft wire spot welding together, the mesh is not limited to do more.

-

Links

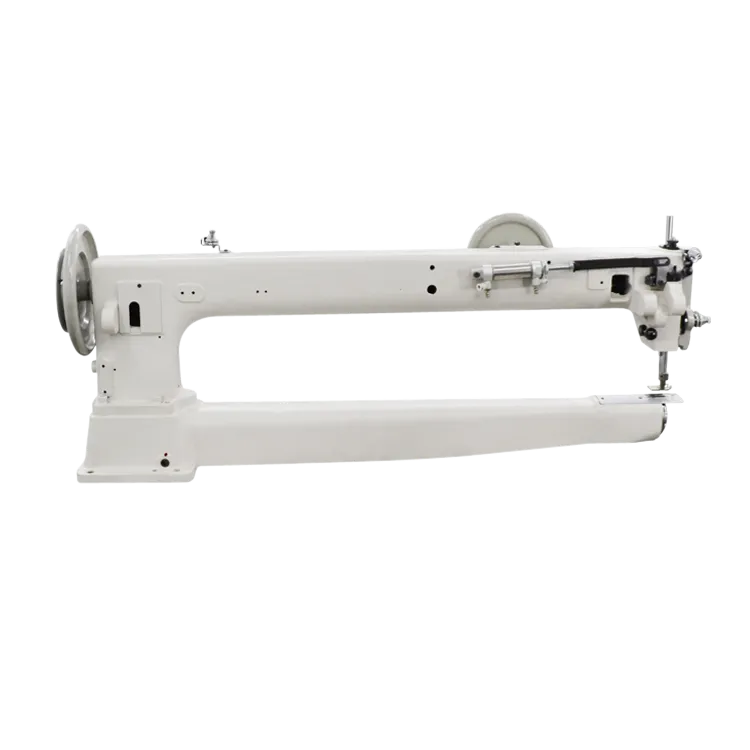

In the world of textile production and leather crafting, the heavy-duty hand stitching machine stands out as an indispensable tool. Combining durability with a remarkable range of applications, these machines offer both hobbyists and professional manufacturers the ability to produce high-quality stitches with ease and precision.

5. Eco-Friendly Aspect With a rising focus on sustainability, the hand crank sewing machine offers an eco-friendly alternative to electric models. Without the reliance on electricity, it reduces the carbon footprint associated with sewing projects.

Typically, the machine head employs methods such as stitching, heat sealing, or gluing to close the bags. Each method has its advantages depending on the type of bag and the contents that need protection. For example, heat sealing is particularly effective for plastic bags as it provides a strong and waterproof closure. On the other hand, stitching is suitable for fabric bags, delivering durability and resistance against tearing during transport.

3. Measuring Tools Accurate measurements are crucial. A fabric measuring tape, ruler, and chalk or fabric pen for marking are vital to achieving the correct dimensions.

- Another advantage of automatic bag closer sewing machines is their durability and reliability. Built to withstand the rigors of continuous use in industrial settings, these machines are designed to last for years with minimal maintenance. This reliability ensures that businesses can count on their equipment to consistently deliver high-quality bag closures, maximizing productivity and profitability.

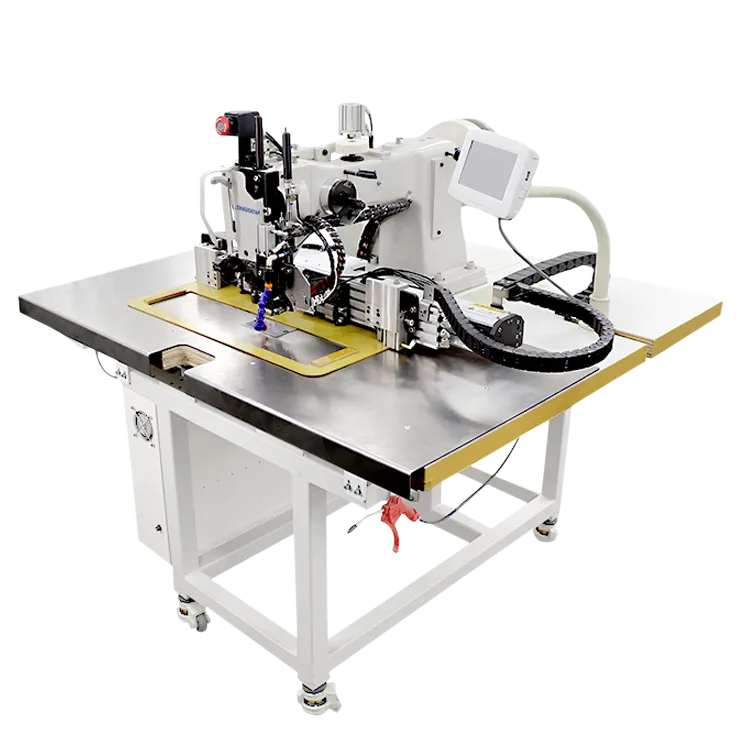

This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality

This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality