punched metal panels

Latest articles

punched metal panelsStainless steel barbed rope is often used in various engineering projects because of its good anticorrosion ability, but it is difficult to be accepted by ordinary families because of its high price. So what material of barbed rope has better anticorrosion ability?

...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read More

punched metal panels

Post time: 27-06-22...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read Morepunched metal panels

...

punched metal panels 【punched metal panels】

Read MoreC, coating uniformity: galvanized layer is basically uniform with copper sulfate solution test etched five times without exposing iron.

punched metal panels...

punched metal panels 【punched metal panels】

Read More

Popular articles

- 1. The center line of the barbed rope protective net is set within 20 to 50 cm of the road land boundary.

Generally, due to wet weather and more precipitation, oxidation and rust of binding iron wire NetEase occurs, so we should better store and use galvanized iron wire to avoid rust as far as possible. About the barbed wire, the surface of the barbed wire attached a layer of galvanized layer, the galvanized layer if too thick will not meet the SGS environmental standards. But if it is too thin, it is easy to oxidize with water molecules and rust.

Fourth, the difference between 201 and 304 is the problem of nickel. And the price of 304 is relatively expensive now, generally close to 20,000 yuan per ton, but 304 can at least ensure that it will not rust in the process of use. (Experiment with potions)

- The production and processing process of blade barbed rope is tedious, which requires the cooperation of all departments, and the production cycle is relatively long. The barbed rope, whether galvanized barbed rope or stainless steel barbed rope, due to the relatively simple structure, the degree of mechanization in the production process is relatively high, so this is also a big difference in the price.

Latest articles

-

The large roll of galvanized silk should be coated with oil, the fiber core is dipped in oil, and the grease should be able to protect the fiber core from decay and corrosion, the iron wire moistens the fiber, and lubricates the wire rope from the inside. The surface is coated with oil so that all the wire surface in the rope strand is evenly coated with a layer of anti-rust lubricating grease, which is used for the mine rope with friction lifting and mineral water, to be coated with black grease with increased wear and strong water resistance. Other uses are coated with red oil oil with strong film and good rust resistance, and require it to have a thin oil layer, which is easy to keep clean during the operation.

-

Post time: 10-11-22 -

That layman how to identify the amount of galvanized, can use the following three methods. Professionals told us that the surface layer of the high-zinc barbed rope would not be particularly smooth due to the zinc behind it, which could be found when comparing the two products. Although the zinc barbed wire zinc layer is thin but relatively smooth.

-

-

Traditional wire mesh is crisscross woven into the wire, with the development of the economy, the rapid rise of all walks of life, the use of traditional wire mesh limitations gradually exposed, such as: aquaculture, to the chicken circle a cage can not be too dense, the wire can not be too thick, woven up the net wire once the mesh is too large net surface will become soft.

-

When the ground is undulating, the installation method of barbed rope also needs to be changed accordingly, because the installation of the original installation method will not play a protective effect.

Understanding Sliding Door Rollers

The stakes are high, and with both materials boasting their own sets of advantages, the decision-making process can feel overwhelming. Below, we’ll compare and contrast these two choices against the most important criteria: aesthetics, cost, durability, security, and more.

Posts and Brackets

One consideration is that exterior-grade windows come with thermal insulation and double-glazed units; these elements are not usually needed inside the home. Where you don’t need specific sound or insulation requirements of double-glazed panes, single-glazed glass creates a better overall look. Internal single-glazed windows are also slimmer in most cases.

1*20GP:Max .length:5.85 meters Loaded quantity: 10 to 12 tons

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.

aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.When choosing an outdoor metal lock box, there are a few factors to consider. The size of the lock box should be appropriate for the items you need to store, and the locking mechanism should be secure and reliable. It's also important to consider the location where the lock box will be placed and ensure that it is well-protected from potential threats.

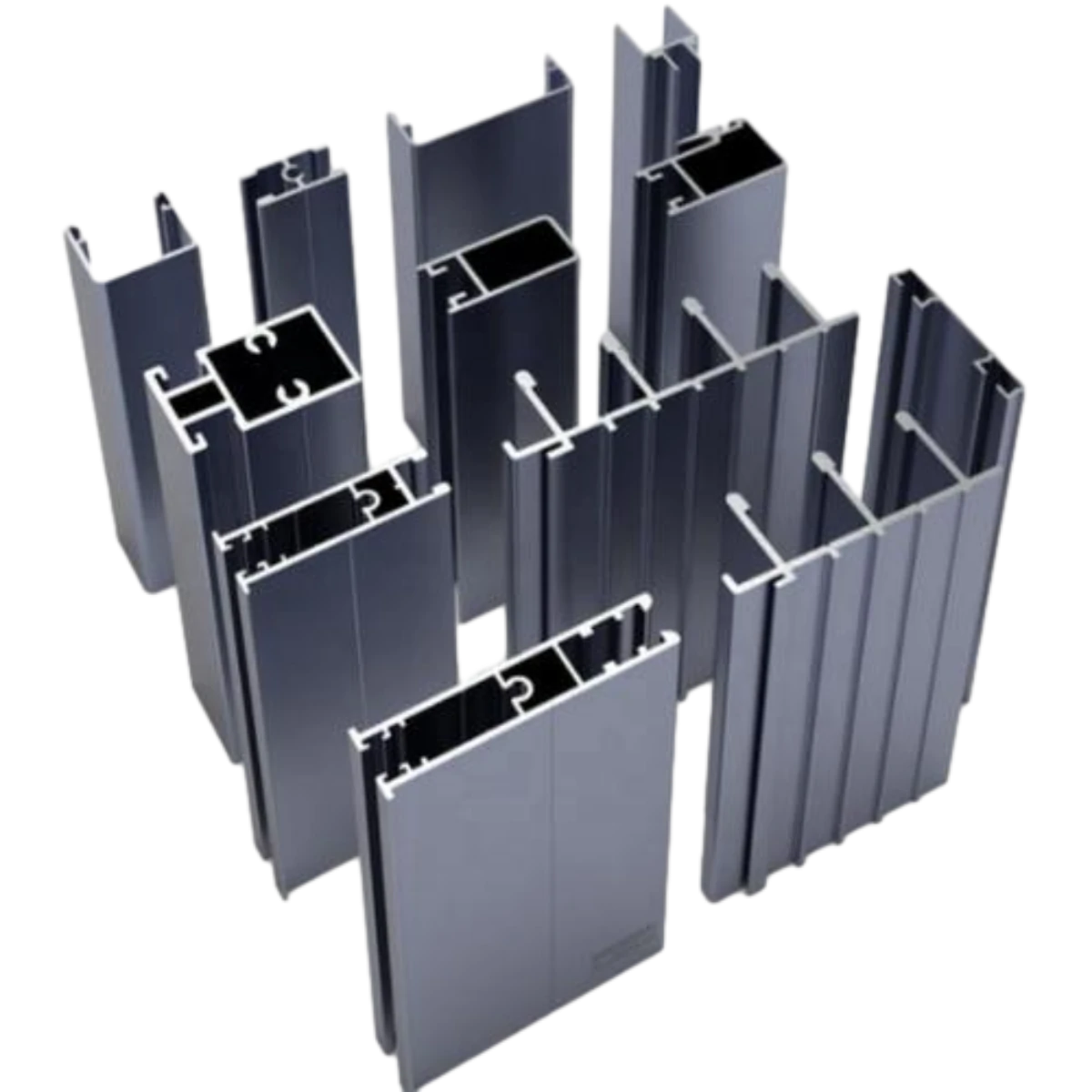

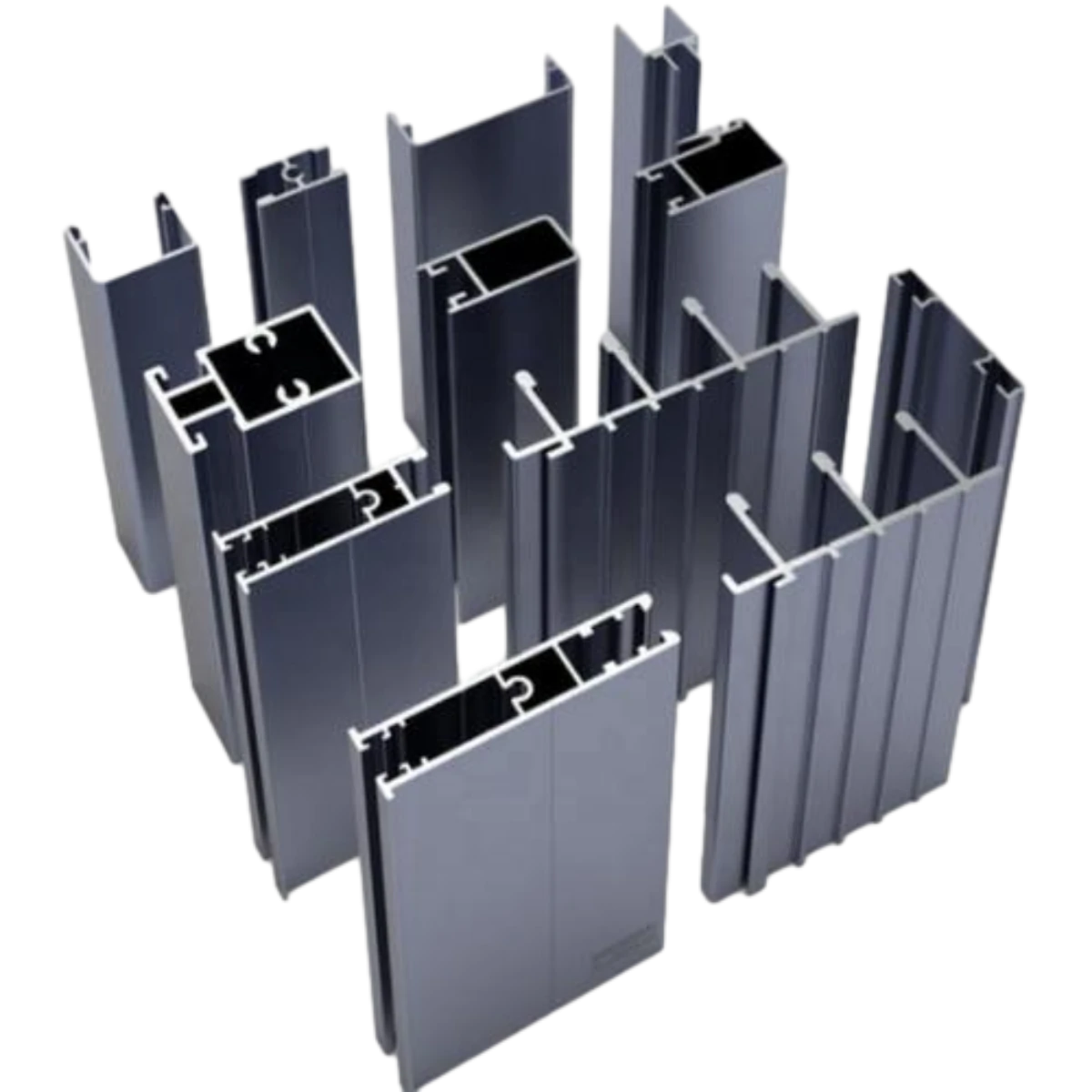

2. Sliding window profile

sliding window roller wheel. By providing a tight seal when closed, they help prevent air leakage, thereby maintaining indoor temperature and reducing energy consumption for heating or cooling. This not only benefits the environment but also translates into cost savings for homeowners.

sliding window roller wheel. By providing a tight seal when closed, they help prevent air leakage, thereby maintaining indoor temperature and reducing energy consumption for heating or cooling. This not only benefits the environment but also translates into cost savings for homeowners.By now the answer should be clear, but if you’re still left with any degree of doubt or uncertainty, which is better: aluminum fence vs wrought iron fence?