wire mesh gauge sizes

Latest articles

wire mesh gauge sizes

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read Morewire mesh gauge sizes

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read MoreHard black galvanized iron wire is made of low carbon steel wire by wire drawing machine. Hard black galvanized iron wire is the first feature of high hardness, bright appearance. It is mainly used for welding clothes hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawing. Soft black galvanized iron wire is the first feature of good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving technology, welding net, process products of welding.

wire mesh gauge sizes...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read Morewire mesh gauge sizes

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read More

wire mesh gauge sizesPoor pretreatment before electroplating; Bath temperature is too low; Poor quality additives or excessive additives and organic impurities can cause poor bonding. The quality of the additive also has an effect on coating foaming. Some additives react incompletely during synthesis and continue to polymerize during long-term storage or use. The additive tends to distort the lattice and create stress, causing the coating to blister.

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read More

wire mesh gauge sizesUsually according to the general people, the blade barbed rope is the guardrail, widely used in garden apartments, military bases, private residential areas, government machinery where there is a fence, generally used blade barbed rope. The biggest advantage of the blade is that the protective effect is good, and the installation and maintenance is very convenient, strong isolation ability, good resistance effect, etc.

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read Morewire mesh gauge sizes

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read More

wire mesh gauge sizesThe barbed wire factory will store the inventory of the barbed wire blade in the appropriate place because of the understanding of the product characteristics.

...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read MoreSome welding methods of galvanized steel mesh will reduce the quality of low carbon steel welded joints, such as electroslag welding. Because the line energy is high, the coarse grains in the heat affected zone of welding will become very coarse, leading to a severe reduction in impact toughness. After welding, it is necessary to normalize with refined grains to improve impact toughness.

wire mesh gauge sizes...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read MoreGalvanized hexagonal mesh uses: building wall fixed, heat preservation, heat insulation; Power plant piping, boiler heating; Anti-freezing, residential protection, landscaping protection; Raise chicken and duck, isolate chicken and duck house, play the role of protecting poultry; Protect and support seawalls, hillsides, roads and Bridges and other waterworks.

wire mesh gauge sizes...

wire mesh gauge sizes 【wire mesh gauge sizes】

Read More

Popular articles

- Galvanized iron wire has excellent endurance and elasticity, zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, wire mesh, highway guardrail, commodity packaging and ordinary civilian and other categories.

- Barbed wire manufacturers focus on galvanized barbed wire, hot galvanized barbed wire, blade barbed wire, stainless steel barbed wire, plastic coated barbed wire, reverse screw barbed wire production for ten years.

Latest articles

-

-

5. The bird cage should be sprayed with transparent wood environmental protection paint every 1-2 years. This protects the cage’s skeleton from the effects of weathering.

-

There is no adhesion test of powder spraying or fluorocarbon spraying on packaged galvanized wire, but there are two points for reference: first, in sealed or air-free environment, non-metallic volatiles can corrode zinc coating; Second, zinc at higher than 230 degrees (c) will cause the matrix metal brittle. And powder spraying and fluorocarbon spraying are to be baked at a higher temperature and in a sealed environment, causing rapid corrosion of zinc, resulting in loose corrosion film resulting in coating adhesion decline, and even lead to (matrix) steel wire brittle situation may exist.

-

Electrode application range is wide, can realize a variety of materials, a variety of profiles and a variety of joint forms of welding. (1) Welding between low carbon steel, low alloy steel, medium carbon steel, alloy steel and other metal materials or dissimilar metal materials can be achieved. The weld has good comprehensive mechanical properties, and the tensile strength can reach more than 400MPa. ⑵ Can realize the welding of large plate, steel frame, plate – tube, rod – rod, tube – tube and other profiles. ⑶, can realize docking, Angle, lap, T joint and other joint forms of welding. ⑷ mainly suitable for flat welding.(5) it can surfacing the parts of wear failure, so as to obtain the surface surfacing layer with melting depth, smooth surface and excellent performance. ⑹ It can be realized that no bevel 1 ~ 6mm thick metal sheet single-side welding double-side molding.

-

Post time: 07-11-22 -

The welding process of galvanized steel wire mesh because of low carbon steel carbon content is low, manganese and silicon content is low, will not occur severe hardening or quenching structure due to welding. The low carbon steel joints have excellent plasticity and impact toughness after welding. In the welding process, it is generally not necessary to preheat, interlayer temperature control, post-heating control and heat treatment to improve the welding structure.

Links

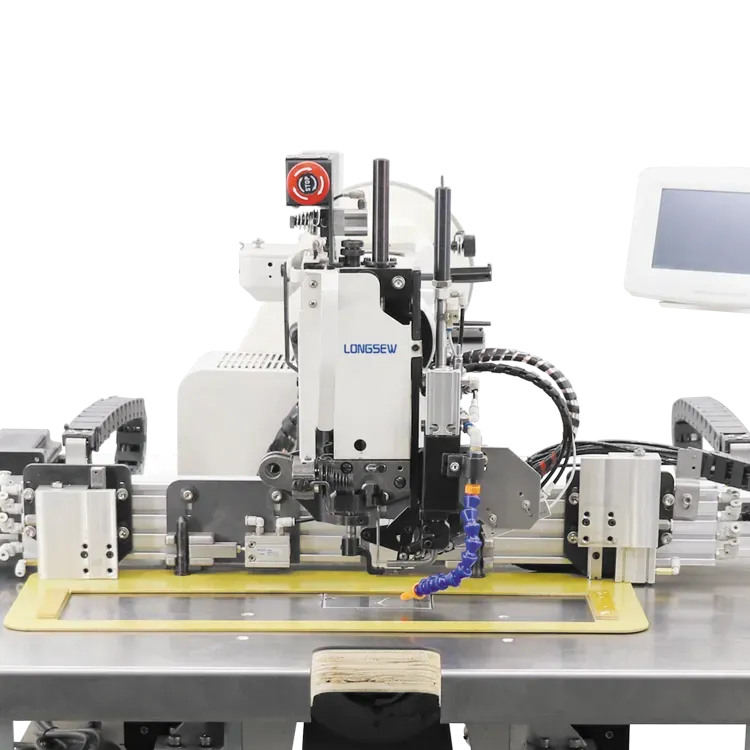

Understanding the PP Bag Silai Machine

Key Features of Industrial Serger Machines

3. Avoid Pins Instead of using pins, consider clips to hold your vinyl in place. Pins can leave holes in the material, while clips provide a more secure hold without damaging the fabric.

At the heart of the modern sewing machine lies the chain stitch mechanism. This technology uses a series of interlocking loops created by a needle and a looper. The chain stitch is distinctive due to its ability to create a durable seam that is both flexible and elastic. Unlike traditional lockstitches, which require two threads to form a cohesive seam, chain stitches use only one thread in a loop, significantly reducing the amount of material needed. This not only lowers costs but also accelerates the sewing process, enabling manufacturers to produce garments at a remarkable speed.

sewing machine chain

4. Stitch Selection A variety of stitch options can be beneficial when working with vinyl. Look for machines that offer straight, zigzag, and decorative stitching. Some machines even come with built-in patterns, providing extra creativity for your projects.

For those involved in the textile and garment industry, understanding the intricacies of hi-speed lockstitch sewing machines is essential. Their significance in improving production efficiency and ensuring quality craftsmanship cannot be overlooked. In a world where fast and reliable manufacturing processes drive success, investing in a hi-speed lockstitch sewing machine is a step towards achieving excellence in sewing operations.

Price

Moreover, a walking foot is beneficial when working with fabrics that have a tendency to stretch or shift, such as knits or certain types of lightweight materials. This foot can help maintain the integrity of the stitch and keep the fabric from distorting as it passes through the machine.

walking foot for thick fabric

self threading sewing machines for sale. Threading a needle can be one of the more intimidating aspects of sewing for beginners, but a self-threading machine can eliminate this hurdle. By removing the need for precise hand-eye coordination, beginners can focus on honing their sewing techniques and creating beautiful projects without the frustration of struggling to thread the needle.

One of the most critical features to look for in a sewing machine for both fabric and leather is stitch control. The ability to adjust the stitch length and type is vital when switching between materials. For instance, when sewing leather, a longer stitch length (usually between 3-5mm) helps reduce the chances of puncturing the material too many times, which can lead to tearing. In contrast, for lightweight fabrics, a shorter stitch length provides greater control and a more refined finish.

sewing machine for fabric and leather

3. Versatility Handheld leather stitchers are versatile tools that can handle various types of leather, from soft suede to thicker, heavier hides. Many models come with interchangeable needles and settings that allow users to adapt the tool for different thicknesses and stitching styles. This adaptability makes it an excellent choice for diverse projects, from wallets and belts to bags and intricate accessories.

handheld leather stitcher

Quality is a key concern for any textile manufacturer. Overlock sewing machines contribute to higher quality outputs by creating durable seams that withstand stress and movement. The overlocking stitch is inherently stronger and more flexible than a standard straight stitch, making it ideal for garments that require stretch, such as athletic wear or fitted clothing. This ensures that the end products do not only look good but also last longer, reducing return rates and improving customer satisfaction.

The evolution of stitching leather machines marks a significant chapter in the history of leathercraft. By merging traditional techniques with modern technology, artisans and manufacturers can produce leather goods that are not only functional but also artistic. As the industry continues to progress, the collaboration between man and machine will likely lead to even more innovative approaches, ensuring that leather stitching remains a revered craft for generations to come. Whether for mass production or bespoke creations, stitching machines stand as a testament to the harmony between artistry and engineering in the realm of leatherwork.

Advantages in Industrial Settings

The Evolution and Significance of Union Lockstitch in Textile Manufacturing

In conclusion, cylindrical bed sewing machines play an integral role in the textile manufacturing process, offering unmatched versatility and efficiency for tubular sewing applications. Their ability to handle complex shapes and provide high-quality finishes makes them indispensable in the production of modern garments. With continuous advancements in technology and design, these machines are likely to evolve further, enhancing productivity and quality in the sewing industry. As manufacturers seek to streamline operations and respond to market demands, investing in cylindrical bed sewing machines will undoubtedly remain a wise choice for achieving excellence in garment production.

The Versatile Zigzag Foot Sewing Machine A Seamstress's Best Friend

Heavy-duty sewing machines are engineered to sew through thick materials such as stubborn leather, heavy webbing, denim, and upholstery. Heavy-duty machines can be used both in a home environment and as industrial sewing machines in a commercial setting. The information will help you find the best sound-quality sewing machine for your individual needs.

Next, pin or clip the fabric pieces together, ensuring everything lines up properly. Using a heavy-duty needle and the appropriate stitch type, sew the pieces together, maintaining consistent seam allowances.

When it comes to sewing, one of the most fundamental techniques employed by sewing machines is the lock stitch. This method is integral to creating strong, reliable seams in a wide range of textiles. Whether you are a novice in the world of sewing or a seasoned tailor, grasping the concept of a lock stitch can significantly enhance your sewing skills and understanding of machine operation.

Conclusion

Key Functions of a Serger Machine

The Importance of Jumbo Bag Lock Stitch in Packaging

In the world of textiles and garment manufacturing, the sewing machine has long been a cornerstone of the industry. Among the various types of sewing machines, the needle feed sewing machine stands out for its ability to enhance efficiency, accuracy, and versatility in fabric handling. This article explores the features, benefits, and applications of needle feed sewing machines, highlighting their significance in modern textile production.

Another significant advantage of double needle sewing machines is their versatility. While they are exceptionally well-suited for leather, they can also handle various other materials, from heavy canvas to synthetic fabrics. This feature allows leatherworkers who also dabble in other sewing projects to invest in a machine that meets multiple needs. Furthermore, many models come equipped with adjustable settings, enabling users to tailor their sewing experience for different fabric thicknesses and types.

Industrial Overlockers for Sale A Comprehensive Guide

One of the primary benefits of using a long arm zig zag sewing machine is the efficiency it offers. The extended throat space enables sewists to work on larger projects without the frustration of fabric bunching. This feature is especially beneficial when quilting, where maintaining fabric integrity is crucial for achieving beautiful patterns. The zig zag functionality further enhances this efficiency. Zig zag stitches not only add decorative elements but also offer strength to seams, particularly in stretch fabrics. This dual capability allows users to explore a broader range of sewing projects, transforming an ordinary sewing experience into a creative adventure.

long arm zig zag sewing machine

Leather crafting is an ancient art that has evolved into a highly specialized field, requiring precision and the right tools to produce quality products. Among the most critical tools in leatherwork is the industrial leather sewing machine. These machines are engineered specifically to handle the unique demands of sewing leather, making them an essential investment for both small businesses and large-scale manufacturers. If you are in the market for an industrial leather sewing machine for sale, it is important to understand its benefits and what to look for when making a purchase.

One consideration for those new to leatherworking is the learning curve associated with manual machines. It may take time to master the coordination required for smooth operations, but the rewarding final product often outweighs the initial challenges. Aspiring leatherworkers can benefit from attending workshops or watching tutorial videos to build their confidence and skills.

The single needle edge cutter machine is known for its straightforward design combined with impressive functionality. Typically, it consists of a single needle and a cutting blade that works in tandem to trim the edges of fabrics neatly. The machine is equipped with a motor that drives the needle up and down to create continuous stitching along the fabric edge.

It is crucial to understand that there are various benefits one can get once they start using these heavy-duty sewing machines. In other words, they will offer you the comfort you need, and it will be easy to work on your project.

1. Standard Foot This is the most common presser foot, ideal for general sewing tasks. It works well for straight stitching and basic construction, making it suitable for beginners learning to sew.

A Guide to Beginner Heavy Duty Sewing Machines

Automotive sewing machines are designed specifically for the demands of the automotive industry. They are typically constructed to handle thick and layered materials like leather, synthetic fabrics, and foam, which are commonly used in car interiors. These machines often come with specialized attachments and stitching patterns that cater to a wide variety of tasks, from sewing intricate seat designs to creating durable door panels.

automotive sewing machine

One of the most notable features of automatic computerized sewing machines is their ability to store and recall stitch patterns. Users can select from a vast library of predefined stitches, ranging from simple straight stitches to complex decorative designs. With just the press of a button, users can switch between patterns, making it possible to create detailed projects without the need for manual adjustments. This versatility not only saves time but also encourages creativity by allowing users to experiment with different designs effortlessly.