4 x 4 welded wire fence panels

Latest articles

4 x 4 welded wire fence panels

...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More

4 x 4 welded wire fence panelsCompared with other galvanizing processes, the cleaning requirements for low carbon steel wire before galvanizing are low. However, under the current trend of increasing the quality level of galvanized layer, some pollutants brought into the plating tank are obviously harmful. Because cleaning galvanized coating wastes a lot of time and reduces the production, it is very important to properly clean and effectively rinse the substrate before electroplating.

...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More4 x 4 welded wire fence panels

...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More

4 x 4 welded wire fence panels

Post time: 22-11-22...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More4 x 4 welded wire fence panels

...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More

4 x 4 welded wire fence panels

Post time: 24-05-23...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More4 x 4 welded wire fence panels

...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More

4 x 4 welded wire fence panels

Post time: 17-11-22...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More

4 x 4 welded wire fence panelsThe galvanized layer forms a particular metallurgical structure that is capable of accepting mechanical damage during transport and use. Every part of the plating can be zinc plated, even in dents, sharp corners and hidden places can be fully maintained. The galvanizing process is more convenient than other coating construction methods, and can avoid the required time after the installation on the site.

...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read MoreHard black galvanized iron wire is made of low carbon steel wire directly drawn by drawing machine. The primary characteristics of hard black galvanized iron wire are high hardness and bright appearance. Primary use for welding hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawn. The primary feature of soft black galvanized iron wire is good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving process, electric welding mesh, welding process products.

4 x 4 welded wire fence panels...

4 x 4 welded wire fence panels 【4 x 4 welded wire fence panels】

Read More

Popular articles

- 4, barbed wire protective net and culvert intersection, such as the ditch is narrow, barbed wire barbed wire protective net can be directly crossed, the ditch is wide, barbed wire barbed wire protective net is difficult to cross, can take the treatment method of bridge, channel.

Compared with electric galvanized iron wire, hot dip galvanized iron wire has higher zinc layer, better anti-corrosion performance, and is suitable for the more important anti-corrosion and anti-rust status.

- 2. Dissolution treatment: Put the pickling steel wire into the dissolution tank, and dissolve the zinc powder with the bath liquid by heating, and the dissolved zinc liquid will adhere to the surface of the steel wire.

The price of galvanized iron wire is relatively low, but the corrosion resistance is excellent, so it is favored by many screen businesses. In the production process of galvanized iron wire, first of all, we should check the equipment to see if there are any problems, and then we should look at the galvanized process, whether there are factors that cause product discoloration. If these problems do not exist, or some of them occur on the same equipment, and some are normal, then we should consider the problem of raw materials at this time.

Latest articles

-

-

In the selection of birdcage, the characteristics of the birds, the way of daily management, the impact of the surrounding environment and so on should be considered. Therefore, it is necessary to have requirements on the shape, structure and technology of the cage, so that the cage can not only be suitable for the birds’ activities, but also delicate and beautiful.

-

-

-

-

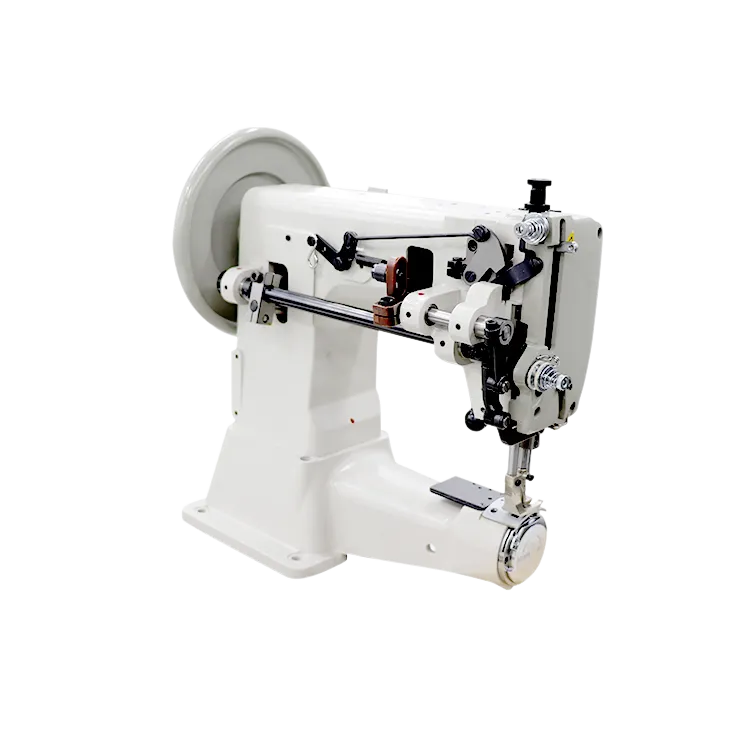

This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear

This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear dressmaker deluxe zig zag.

dressmaker deluxe zig zag.