diamond metal mesh panels

Latest articles

diamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read Morediamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read Morediamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read Morediamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read MoreAttention should be paid to line collection and operation. Others shall not get on the train without the monitor’s consent. The wire reel should be put lightly, stacked firmly and neatly, not more than 5 discs. It is forbidden to contact human skin directly with acid and base. When the acid fog exceeds the specified target of the state, timely measures should be taken to control it; otherwise, production is not allowed.

diamond metal mesh panels...

diamond metal mesh panels 【diamond metal mesh panels】

Read Morediamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read More

diamond metal mesh panels

Post time: 10-05-23...

diamond metal mesh panels 【diamond metal mesh panels】

Read MoreThe most obvious difference in a short time is the cross section of this piece, hot dip galvanized barbed wire because of surface anticorrosion treatment, so there will be rust in the cross section of this piece, and stainless steel barbed wire because the internal raw materials and surface raw materials are consistent, so there is no such situation.

diamond metal mesh panels...

diamond metal mesh panels 【diamond metal mesh panels】

Read Morediamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read Morediamond metal mesh panels

...

diamond metal mesh panels 【diamond metal mesh panels】

Read More

Latest articles

-

6. Before commencing work or extending the period from time to time, cut off 15-20 feet of steel wire from the reel and reknot it, in order to prevent the knot from breaking due to fatigue.

-

-

Post time: 13-06-22 -

The antisepsis of these materials is very different, the use of life is not the same. Cold galvanized cattle net, also known as electroplating, galvanized amount is small, rust in rain, but the price is cheap, the service life is 5-6 years. The amount of zinc on hot dip galvanizing (low zinc and high zinc) is about 60g to 400g, the service life is about 20-60 years, and the corrosion resistance is general.

-

-

2, pasture installation of thorn rope spacing, if it is cattle or horses due to the larger size, the spacing can be appropriately relaxed. But if it’s a sheep, it’s a smaller animal and you have to make it a little bit narrower.

Links

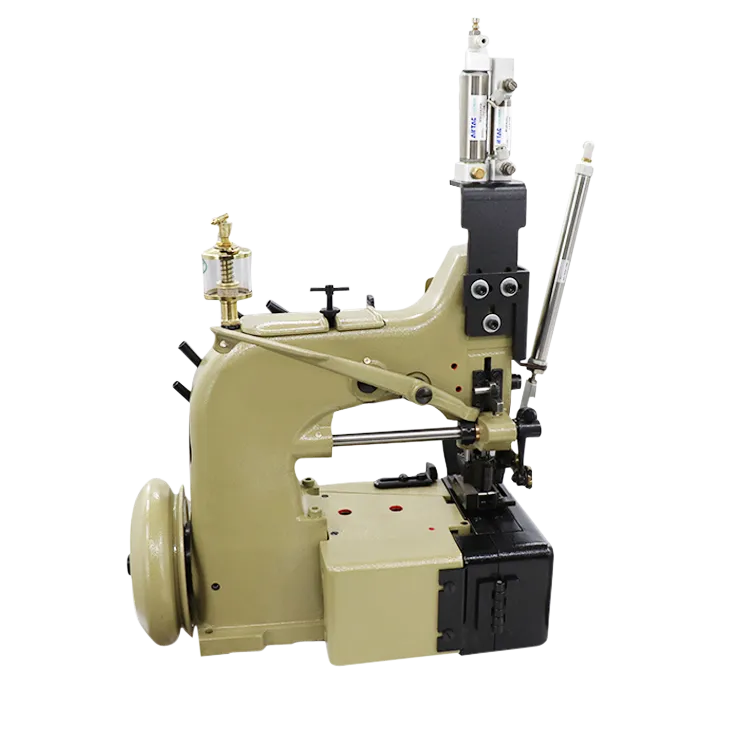

The Importance of Plastic Bag Closer Machines in Modern Manufacturing

- One of the key features of the Cub Leather Sewing Machine is its portability. It is small and lightweight, making it easy to transport from one place to another. This means you can take it with you to craft shows, workshops, or even just move it around your own workspace without any hassle.

- The single lockstitch machine, an engineering marvel that revolutionized the textile and garment industry, is an essential tool in modern sewing. This innovative device, with its simple yet effective mechanism, has been a cornerstone of clothing production since its inception.

Compound feed and triple feed sewing machines offer unmatched precision and durability for heavy-duty sewing tasks. Their advanced feeding mechanisms ensure consistent fabric movement and stitch quality, making them invaluable assets for industrial sewing operations. Elevate your production capabilities—buy a compound feed sewing machine today and experience the difference it can make.

Conclusion

- Sewing machines have become an essential tool for anyone who wants to work with leather or canvas. These heavy-duty fabrics can be difficult to sew by hand, but with the right machine, you can easily create professional-quality projects. When looking for a sewing machine for leather and canvas, there are a few key features to consider.