barbed wire for pigs

Latest articles

barbed wire for pigs

...

barbed wire for pigs 【barbed wire for pigs】

Read Morebarbed wire for pigs

...

barbed wire for pigs 【barbed wire for pigs】

Read Morebarbed wire for pigs

...

barbed wire for pigs 【barbed wire for pigs】

Read MoreThe drawing process of waste product drawing process has a great influence on product function. Generally, large total surface reduction rate (see area reduction rate) and small pass surface reduction rate (about ≤23%) are selected to ensure the tolerance of products. About high strength spring steel wire, the exit temperature of each pass steel wire should be controlled when drawing below 150℃, to prevent the steel wire from changing cracks due to strain aging, which is the main disadvantage of steel wire obsoletion.

barbed wire for pigs...

barbed wire for pigs 【barbed wire for pigs】

Read More

barbed wire for pigs...

barbed wire for pigs 【barbed wire for pigs】

Read Morebarbed wire for pigs

...

barbed wire for pigs 【barbed wire for pigs】

Read More

barbed wire for pigs

Post time: 12-06-24...

barbed wire for pigs 【barbed wire for pigs】

Read More6. It’s easy for your dog to get used to a strange place as long as it has a home he’s familiar with, so you can take your dog on a trip instead of leaving him at home.

barbed wire for pigs...

barbed wire for pigs 【barbed wire for pigs】

Read More4, according to the wire diameter thickness to adjust zinc dipping time

barbed wire for pigs...

barbed wire for pigs 【barbed wire for pigs】

Read MoreThe blade thorn rope is formed by the punching steel plate and mechanically rolled on the steel wire. The width of the blade is 22mm, the vertical distance between the two blades is 15mm, the longitudinal distance between the blade is 34mm, and the diameter of the core wire is 2.5mm. The blade is made of Q195 steel plate with 0.5mm thickness.

barbed wire for pigs...

barbed wire for pigs 【barbed wire for pigs】

Read More

Popular articles

Bridge protection system generally do not need to install special drainage system, the use of hexagonal mesh gabion cage, the filling is selected stones, the stones are not easy to wear, and between the stones and stones will retain some space, so it is very good to meet the drainage requirements.

Uses: water conservancy engineering, river regulation engineering, dike engineering, ecological protection engineering, channel lining, road engineering, river bank reinforcement, ocean engineering, landscape design engineering, bridge reinforcement, railway and highway slope protection, retaining wall, ecological river bank slope regulation and other engineering.

- The zinc layer on the galvanized wire has good ductility, can be cold blanking, rolling, bending and other molding without damage to the zinc layer. The zinc layer of galvanized wire with thick zinc layer has fine crystallinity, uniform and no void, and good corrosion resistance. The zinc layer obtained by electrogalvanizing is very pure and corrodes slowly in the gas, liquid and fog of acid and alkali, which can effectively protect the steel matrix. Galvanized layer can also be chromate passivation into a variety of colors, beautiful and generous, with good decoration.

Latest articles

-

-

When galvanized wire is galvanized, it is generally necessary to pay attention to the following problems: the duration of the protective effect of galvanized wire is greatly related to the thickness of the coating. Generally speaking, in the dry main gas and in indoor use, the thickness of galvanized wire galvanized layer only 6-12 μm “, and in harsh environmental conditions, galvanized wire galvanized layer thickness needs 20μm “to B height up to 50μm”. Therefore, the environmental impact should be considered when choosing the thickness of galvanized layer. Galvanized wire in galvanized, pay attention to the above problems, can be well galvanized, to ensure the quality of galvanized wire.

-

Post time: 30-05-23 -

-

-

Links

- 4’ x 12’

- The versatility of fiberglass covers extends beyond these examples, finding utility in everything from HVAC systems to decorative art pieces. Their ability to be molded into various shapes and sizes, coupled with their resistance to corrosion and weathering, makes them a go-to solution for designers and engineers alike.

- Another benefit of fiberglass chemical tanks is their flexibility. They come in a variety of sizes and shapes, allowing them to be customized to fit specific needs. This makes them particularly useful in industries where space is limited or where specialized storage requirements must be met.

Custom Colors & Sizes:

rock button bit. Construction companies use these specialized drill bits to create foundation holes, bore tunnels, and excavate rock for building projects. The rock button bit is essential for ensuring precise and efficient drilling, allowing construction projects to progress smoothly and on schedule.

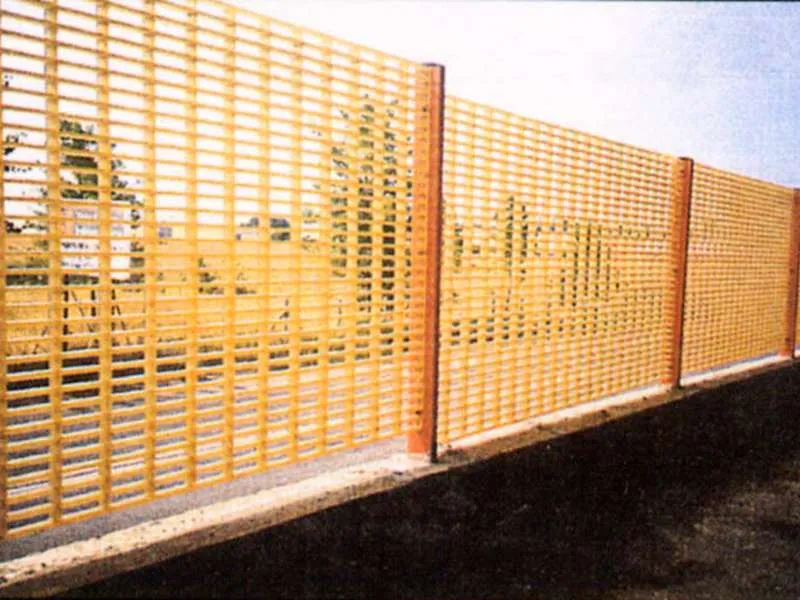

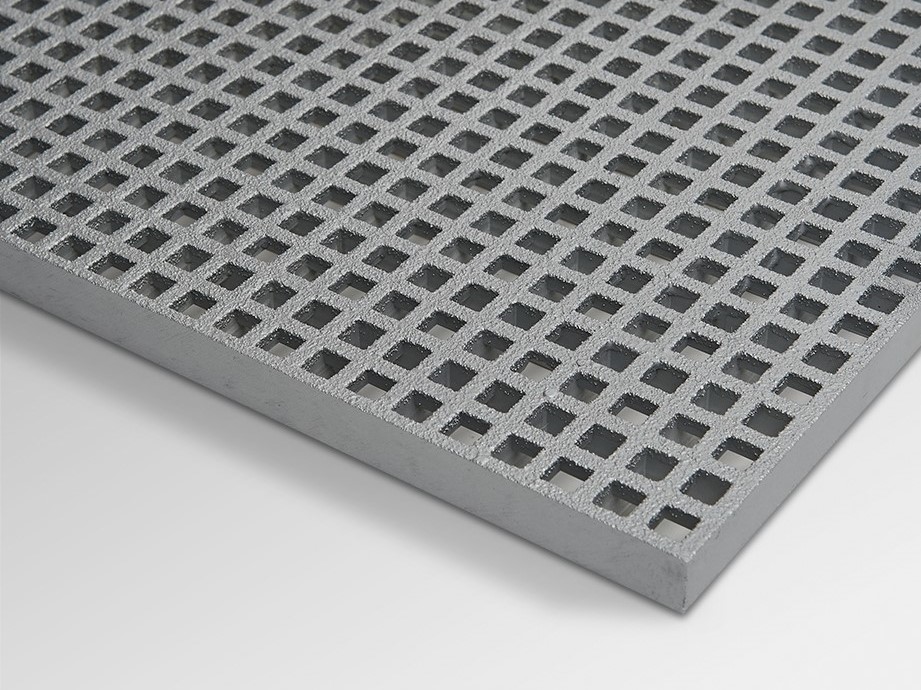

rock button bit. Construction companies use these specialized drill bits to create foundation holes, bore tunnels, and excavate rock for building projects. The rock button bit is essential for ensuring precise and efficient drilling, allowing construction projects to progress smoothly and on schedule.An excellent alternative to the metal grating system, fiberglass is more cost effective, durable and with plenty of safety benefits, making it a popular choice for general and industrial use.

thread button bit. Its unique design enables it to maintain a cooler operating temperature, thereby reducing wear and tear and prolonging the bit's lifespan. This, in turn, reduces costs associated with frequent replacement and maintenance.

thread button bit. Its unique design enables it to maintain a cooler operating temperature, thereby reducing wear and tear and prolonging the bit's lifespan. This, in turn, reduces costs associated with frequent replacement and maintenance.

This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology

This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology This flexibility makes it a popular choice among professionals in fields such as construction, mining, and geology anchor drill bit.

anchor drill bit.FRP grating is known for being durable in all kinds of environments. It can be exposed for long periods of time to the elements without showing any signs of wear and tear.