what screws to use on drywall

Latest articles

what screws to use on drywall

Post time: 16-11-22...

what screws to use on drywall 【what screws to use on drywall】

Read More

what screws to use on drywall

Post time: 06-09-22...

what screws to use on drywall 【what screws to use on drywall】

Read More

what screws to use on drywallThe main difference is carbon content. Iron has a carbon content of 2.11 percent or more, while steel has a carbon content of 2.11 percent or less. Iron-carbon alloys with carbon content of more than 2.11% are cast iron (pig iron), which are basically not malleable and cannot be drawn into wire. Secondly, the content of impurities is different, and the content of harmful impurities such as sulfur and phosphorus in steel is smaller. Wire general color key, wire color light point, white point.

...

what screws to use on drywall 【what screws to use on drywall】

Read More

what screws to use on drywall4. Keep the rinse water clean after pickling the steel wire

...

what screws to use on drywall 【what screws to use on drywall】

Read Morewhat screws to use on drywall

...

what screws to use on drywall 【what screws to use on drywall】

Read Morewhat screws to use on drywall

...

what screws to use on drywall 【what screws to use on drywall】

Read More

what screws to use on drywallThe anticorrosion of these raw materials are very different, the use of life is not the same. Cattle fence cold galvanized, also known as electroplating, galvanized little, rust in rain, but the price is cheap, the use of life in 5-6 years. Hot dip galvanizing (low zinc and high zinc) zinc content in 60 grams to 400 grams, the use of life is about 20-60 years, corrosion resistance is general.

...

what screws to use on drywall 【what screws to use on drywall】

Read More

what screws to use on drywallWe can complete the installation of ordinary double-strand barbed rope by using wood shaft or even trees, but the blade barbed rope has high requirements for construction.

...

what screws to use on drywall 【what screws to use on drywall】

Read Morewhat screws to use on drywall

...

what screws to use on drywall 【what screws to use on drywall】

Read More

what screws to use on drywallGalvanized iron wire will rust, mainly and the thickness of galvanized layer and the use of the environment, galvanized iron wire is also divided into cold galvanized iron wire and hot galvanized iron wire, in general, hot galvanized iron wire galvanized layer is thicker, rust prevention time is longer, generally can be 7 or 8 years without rust. If the galvanized layer is damaged, or long-term use in a humid environment, it will accelerate the rust time of galvanized iron wire.

...

what screws to use on drywall 【what screws to use on drywall】

Read More

Popular articles

Latest articles

Links

- Moreover, the company's dedication to customer service and support is unparalleled. With comprehensive training programs, responsive technical assistance, and a global network of authorized service centers, Tio2 ensures that its clients have the resources they need to maximize the potential of their BLR-895 investment.

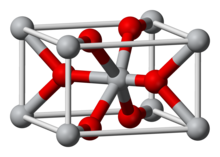

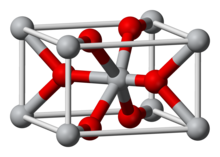

Production[edit]

Basic Information:

Fig. 8. Selected images of skin stratus treated with P25TiO2NPs 10% (left) and VitaminB2@P25TiO2NPs 10% (right) under light, showing no penetration of the nanoparticles (white arrows) beyond the outer stratum corneum.

Here it has been shown that functionalization of P25TiO2NPs with vitamin B2 was able to significantly decrease the oxidative stress produced when they are exposed to sunlight. This finding is of main importance to prevent skin damage and toxicity of sunscreens containing this form of untreated titanium dioxide and should be taken into consideration when updating the regulations mentioned above .

Research supports that applying titanium dioxide to the skin in the form of sunscreens, makeup, and other topical products does not pose any health risks.

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.

talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.4.Used as a white pigment, the hiding power is second only to titanium dioxide, but stronger than zinc oxide. The hiding power increases as the ZnS content increases, and the light resistance also improves, but the acid resistance decreases.

Ability to scatter and absorb UV radiation makes TiO2 a crucial ingredient for sunscreen, protecting the skin from harmful, cancer-causing UV rays.

Is titanium dioxide illegal in other countries?

Molar mass: 412.23

In order to achieve the same solids content, the larger filler and the binder should be reduced if necessary.

Is Titanium Dioxide Safe?

Composition

While IARC listed titanium dioxide as “possibly carcinogenic to humans,” they also add that “there is inadequate evidence in humans for the carcinogenicity of titanium dioxide.” Of the four human studies that they reviewed, only one showed a potential risk for occupational workers inhaling titanium dioxide particles and lung cancer, while the other three showed no risk for cancer at all. And it’s key to note that IARC did not assess the effects of titanium dioxide found in foods.

There are two primary forms of titanium dioxide commercially available: anatase and rutile. The rutile form is typically used in sunscreens due to its superior ability to handle UV rays and stability in the presence of UV light. The anatase form is typically used in other types of products, such as paint. Another plus of the rutile form is that its UVA protection extends past 400 nanometers, which is the upper limit of UVA.

CSPI says it might reconsider its rating if specifications for food-grade titanium dioxide in the U.S. are updated to ensure nanoparticles are minimized, and new studies are conducted to assess its capacity to cause cancer or other health problems.

For a mini-review published in the journal Particle and Fibre Technology in 2021, scientists wanted to evaluate whether Ti02 particles contributed to the development and/or exacerbation of irritable bowel disease, and whether they altered the four elements of intestinal barrier function: the intestinal microbiota, the immune system, the mucus layer, and the epithelium. The breakdown of these four elements can contribute to autoimmune, neurological, inflammatory, infectious, and metabolic diseases. Following their review, the researchers concluded: “Data indicate that TiO2 is able to alter the four compartments of IBF and to induce a low-grade intestinal inflammation associated or not with pre-neoplastic lesions.”

Overwhelmingly, research that’s relevant to human eating patterns shows us that E171 is safe when ingested normally through foods and drugs (1,2).

According to a 2011 study published in Radiology and Oncology, titanium dioxide may lead to some adverse effects in the body, including oxidative stress, inflammation, and changes in cell signaling pathways. Additionally, pure titanium dioxide can be notably harmful when inhaled.

Packaging containing this additive has been shown to decrease ethylene production in fruit, thus delaying the ripening process and prolonging shelf life (4Trusted Source).