hot dipped siding nails

Latest articles

hot dipped siding nails

...

hot dipped siding nails 【hot dipped siding nails】

Read Morehot dipped siding nails

...

hot dipped siding nails 【hot dipped siding nails】

Read More

hot dipped siding nailsNow large roll galvanized wire in our life the use of more and more, to galvanized wire products bring a great market, galvanized wire products are more and more types. The surface coating of good quality galvanized wire is continuous and smooth. When the plating parts are installed and combined, there can be no flow hanging, slag or drop remaining, and no surface defects such as iron exposure. Good quality galvanized wire, coating must be uniform, roughly uniform in copper sulfate solution soaking five times without exposing iron. And with hammering test does not bulge, do not fall off. This is a good galvanized wire should have characteristics.

...

hot dipped siding nails 【hot dipped siding nails】

Read MoreAfter a long time of use, it will not rust like the corrosion layer on the surface of hot dip galvanized barbed rope, because the internal material of stainless steel barbed rope is the same as the material on the surface.

hot dipped siding nails...

hot dipped siding nails 【hot dipped siding nails】

Read More

hot dipped siding nailsWhen the ground is undulating, the installation method of barbed rope also needs to be changed accordingly, because the installation of the original installation method will not play a protective effect.

...

hot dipped siding nails 【hot dipped siding nails】

Read More

hot dipped siding nailsThe lighting surface of each type of shed is designed to be curved, improving the Angle of the light surface, because the lighting surface is curved, no dust accumulation, good light transmittance, high temperature in the shed, after measurement, the average temperature in the shed is 3℃ higher than the traditional bamboo pole cement column shed, the yield is increased by 15~20%, and the harvest date is advanced. The formula is scientific, the surface does not absorb moisture, do not return halogen through modification technology and scientific production process, solve the greenhouse frame rod is easy to absorb moisture return halogen, poor water resistance and easy to change the shortcomings, so that the greenhouse steel pipe in the high temperature and high humidity environment, few drops, frost phenomenon, and reduce pests and diseases.

...

hot dipped siding nails 【hot dipped siding nails】

Read More

hot dipped siding nails

Post time: 01-11-22...

hot dipped siding nails 【hot dipped siding nails】

Read Morehot dipped siding nails

...

hot dipped siding nails 【hot dipped siding nails】

Read Morehot dipped siding nails

...

hot dipped siding nails 【hot dipped siding nails】

Read More

hot dipped siding nailsAccording to the different requirements of the industry, different weights of alloy ingots are put in the smelting furnace according to the standard, such as weaving, Ming, paper, lang, silicon, etc., and the data out of this smelting is called gold ore iron. Iron has gray iron, white iron and the above-mentioned gold, they have different characteristics, so in the industry according to their different characteristics to transport and selection. For example, in gray iron, its carbon exists in iron ore in graphite condition, the crack is often gray, soft and strong, simple filtering, suitable for casting.

...

hot dipped siding nails 【hot dipped siding nails】

Read More

Popular articles

Post time: 07-06-22The application of electric welding mesh is more widely, at present, it has replaced the use of other parts of the screen, the cost of electric welding mesh is low, the production speed is very fast, so it is very popular. The treatment required before galvanized welding mesh is recrystallization annealing, because the welding mesh must maintain an oxide and no other impurities of pure iron active surface, if you can’t keep its surface clean will lead to poor galvanized effect, galvanized layer and iron material is not tightly combined, so this step is necessary.

Post time: 06-01-23- The common barbed rope produced by the manufacturer is the 14*14 type of barbed rope product. Since the warp wire used is the same as the wire diameter of the barbed rope, it is easier to calculate the length and weight. Usually each kilogram of barbed rope can reach about 10 meters of service length. The length of each kilogram of raw material is about 35 meters. Since 35 meters of raw material wire diameter can produce 10 lengths of barbed rope cost.

Latest articles

-

Black iron wire application in the process, the main is through the hot metal billet rolling into six point five mm wire rod, and then put it in the drawing into a line of different diameter, the plant and then gradually narrow drawing plate aperture, cooling and annealing, plating process, such as making a variety of different specifications of the wire, the wire compared with ordinary black iron wire, will be more softer, Softness is also very uniform, color is also consistent, widely used in the construction industry, mining, chemical industry, welding mesh, welding coat hanger, reprocessing industry and so on.

-

-

Maintenance is indispensable in the use of galvanized wire. Large coils of galvanized silk should be coated with oil, fiber core immersion oil, oil is required to protect the fiber core is not rotten, not rust, wire moisture fiber, and from the internal lubrication wire rope. Surface coating so that all wire rope strands in the surface, are evenly coated with a layer of rust-proof lubrication grease, which for friction lifting and mineral water large mine rope, to be coated with grinding and water-resistant black oil grease. Coated with red oil with strong film and good rust resistance, it is required to have a thin oil layer, which is easy to keep clean during operation.

-

There are too many fake things on the market now, so shoppers should learn how to distinguish the quality of galvanized wire, the right to protect their consumers’ rights and interests. Galvanizing process of galvanized wire products is a very effective metal anticorrosion method, and it is also widely used in other industrial fields. After galvanizing, iron wire is commonly used in metal structure equipment of various industries.

-

-

The characteristics of galvanized hexagonal net: easy to use; Save transportation costs. It can be shrunk into small rolls and involved in moisture-proof paper packaging, taking up little space. Coating thickness uniformity, stronger corrosion resistance; The construction is simple and does not require special technology; Strong resistance to natural damage and corrosion resistance and adverse weather effects; Can withstand a large range of deformation, and still not collapse. It has the function of fixed heat preservation and insulation.

Links

Self fusing tape is a type of self-adhesive tape that can be used for emergency or temporary repairs to electrical wires, plumbing and hoses.

- One of the key advantages of butyl rubber waterproofing is its longevity. Its resistance to ozone, ultraviolet radiation, and chemical exposure ensures a long service life, reducing the need for frequent maintenance or replacements. Furthermore, its excellent fatigue resistance means it can endure constant movement and deformation without losing its sealing effectiveness.

- Despite these advantages, users must be mindful of the limitations of butyl rubber adhesive tape. While it exhibits great cohesion, its initial adhesion to surfaces may not be as strong as other types of tapes. Thus, proper surface preparation and application techniques are essential to maximize its performance.

- Diall self-fusing tape is a versatile and practical tool for a variety of applications. This unique tape is designed to bond to itself, creating a strong and durable seal without the need for adhesive. It is a handy accessory to have in your toolbox, whether you are a DIY enthusiast or a professional tradesperson. In this article, we will explore the uses and benefits of Diall self-fusing tape.

- Self-bonding rubber tape, an innovative and versatile material, has revolutionized the way we approach sealing, insulation, and repair tasks across various industries. This unique tape is essentially a rubber-based adhesive system that adheres to itself, forming a robust, waterproof, and durable bond when applied. It is particularly valued for its ability to stick to itself without the need for external adhesives, making it a highly convenient solution for a multitude of applications.

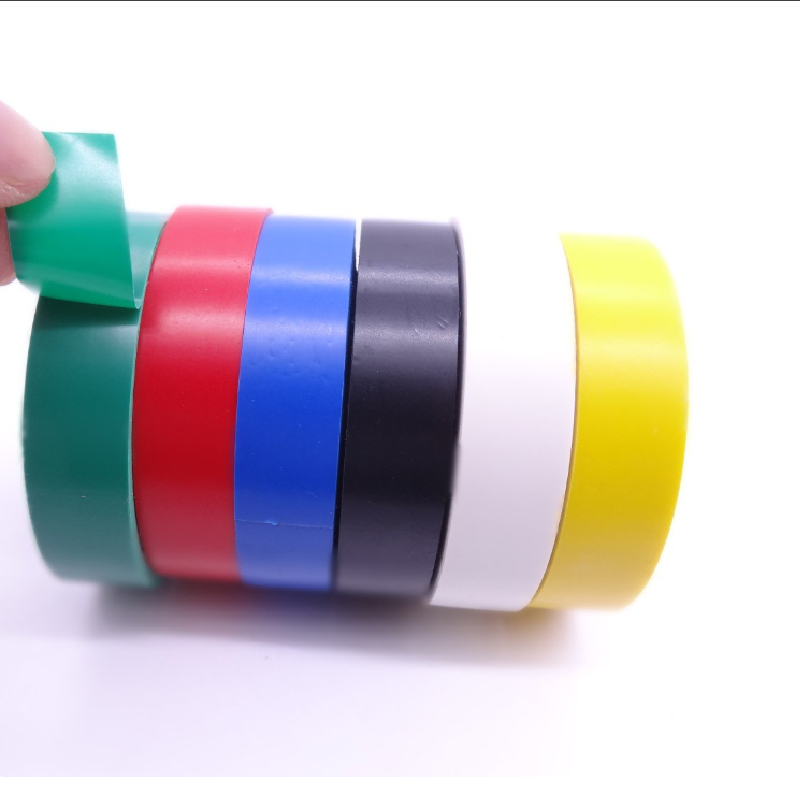

- 3. Protection PVC tapes can protect wires, cables, and other components from abrasion, moisture, chemicals, and other environmental factors.

Price

In conclusion, fireproof gasket tape is an essential tool for ensuring safety and efficiency across various industries. Its ability to withstand high temperatures, combined with its cost-effective and durable nature, makes it a preferred choice for organizations looking to enhance their fire safety protocols. By implementing fireproof gasket tape, businesses can protect their assets, ensure the well-being of their employees, and promote a culture of safety and responsibility in the workplace. As industries continue to evolve, the importance of incorporating reliable fireproof solutions will remain a priority in achieving operational excellence and safeguarding life and property.

In conclusion, a door bottom seal rubber strip is a practical and efficient solution for improving the insulation and weatherproofing of your doors. By creating a barrier against drafts, moisture, and dust, these strips can help to enhance the energy efficiency and comfort of your home. Invest in a high-quality rubber strip today and enjoy the benefits of a well-insulated and protected living space.

The Anatomy of a Control Box

In addition to safety, fire-resistant electrical tape can increase the longevity of electrical connections. Regular electrical tape may degrade over time, especially under extreme conditions, leading to insulation failures. The durability of fire-resistant tape means it can withstand harsher conditions, thereby extending the lifespan of electrical installations.

Lighting and A/V Electrical Control Boxes

It can also deter pests and dust, ensuring a cleaner living or working space It can also deter pests and dust, ensuring a cleaner living or working space

It can also deter pests and dust, ensuring a cleaner living or working space It can also deter pests and dust, ensuring a cleaner living or working space door seal tape. For homes with pets or young children, the added security provided by the sealant tape can be invaluable, preventing accidental exits or unwanted intrusions.

door seal tape. For homes with pets or young children, the added security provided by the sealant tape can be invaluable, preventing accidental exits or unwanted intrusions.Applications of Butyl Rubber Tape