coil master nails

Latest articles

coil master nails

...

coil master nails 【coil master nails】

Read Morecoil master nails

...

coil master nails 【coil master nails】

Read MorePacking is also very important. The cut wire should be bundled and tightly packed with plastic film, and then placed in a regular box. The whole box should be filled and sealed. It is better not to have half a box.

coil master nails...

coil master nails 【coil master nails】

Read Morecoil master nails

...

coil master nails 【coil master nails】

Read MoreBut there are some necessary precautions in the production of galvanized wire. Remove all tools and piles on the work site and equipment that hinder activities, and slowly put the wire into the cylinder during pickling to prevent acid splashing on the body. When adding acid, the acid must be slowly poured into the water. Do not pour water into the acid to prevent acid spillage and injury. Workers should wear protective glasses when working. Then in the handling of wire and other items, it is strictly prohibited to push hard.

coil master nails...

coil master nails 【coil master nails】

Read More

coil master nailsIn reinforced concrete structure, the crack width of cold wire drawing is smaller than that of circular steel bar or even that of hot rolled thread bar. So cold wire drawing is more popular in the construction industry. The material for cold drawing is made of steel bars and can be simply explained how it is made, that is, its production process is simple. It’s based on steel bars, which are constantly stretched evenly, stretching the bars into something very thin, like wire drawing, without plasticity.

...

coil master nails 【coil master nails】

Read Morecoil master nails

...

coil master nails 【coil master nails】

Read MoreIn white iron, its carbon and iron phase into iron carbide, crack white, extremely strong and brittle, for the malleable steel material. Alloy grades are made up of various alloying elements with different compositions and structures. Because the alloy element in the iron can make the copper material thick strengthening degree, hardness, impact force, strength resistance, collection rate, elongation rate, so the alloy iron in the exercise of high quality iron, is an additive element.

coil master nails...

coil master nails 【coil master nails】

Read More

coil master nailsGalvanized wire is processed from low carbon steel wire rod, after drawing forming, pickling rust removal, high temperature annealing, cooling and other processes. Galvanized wire is widely used. Electroplating temperature should be controlled at 30 to 50℃. Because the chloride ions in the bath are very corrosive, quartz glass heaters are generally used.

...

coil master nails 【coil master nails】

Read Morecoil master nails

...

coil master nails 【coil master nails】

Read More

Popular articles

Post time: 13-09-22

Post time: 20-10-22- When the barbed rope is installed in different places, the choice of barbed rope column is different. Usually, the barbed rope column we install is cement column, but the use of cement column also has its drawbacks. For example, it’s not so convenient if we install it on a steep hill where transportation is not very convenient. This time can use barbed rope with the composite column to install.

Latest articles

-

-

Packaging: electric welding net general packaging for moisture-proof paper (color is mostly gray white, yellow, plus trademarks, certificates, etc.), some like 0.3-0.6mm domestic sales of small wire diameter electric welding net, because the wire is relatively soft, coupled with small volume, customers often require packing processing, in order to prevent shipment caused by damage. The wire of electric welding mesh has straight, also has a wavy bend (also known as the Dutch net)

-

-

The material of small hexagonal mesh is the same as that of other hexagonal mesh, which is generally made of low carbon steel wire, stainless steel wire and galvanized steel wire as raw materials by the hexagonal mesh machine.

-

-

Poor pretreatment before plating; Bath temperature is too low; Poor quality of additives or too many additives and organic impurities will cause poor bonding. The quality of additives also has an effect on coating foaming. Some additives react incompletely during synthesis and continue to polymerize during long-term storage or use. The additive tends to distort the crystal lattice and cause stress, causing the coating to bubble.

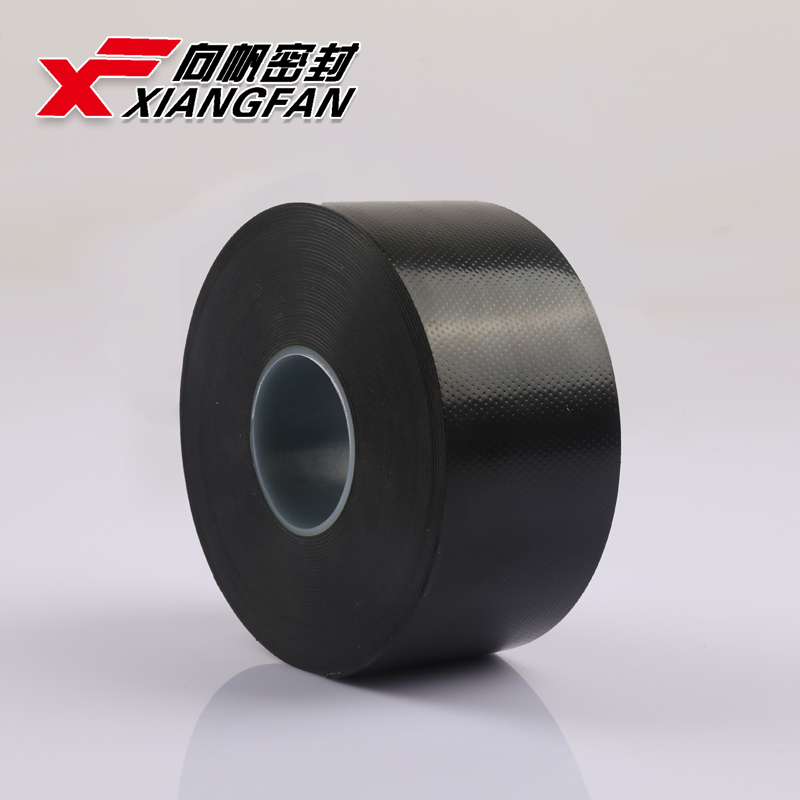

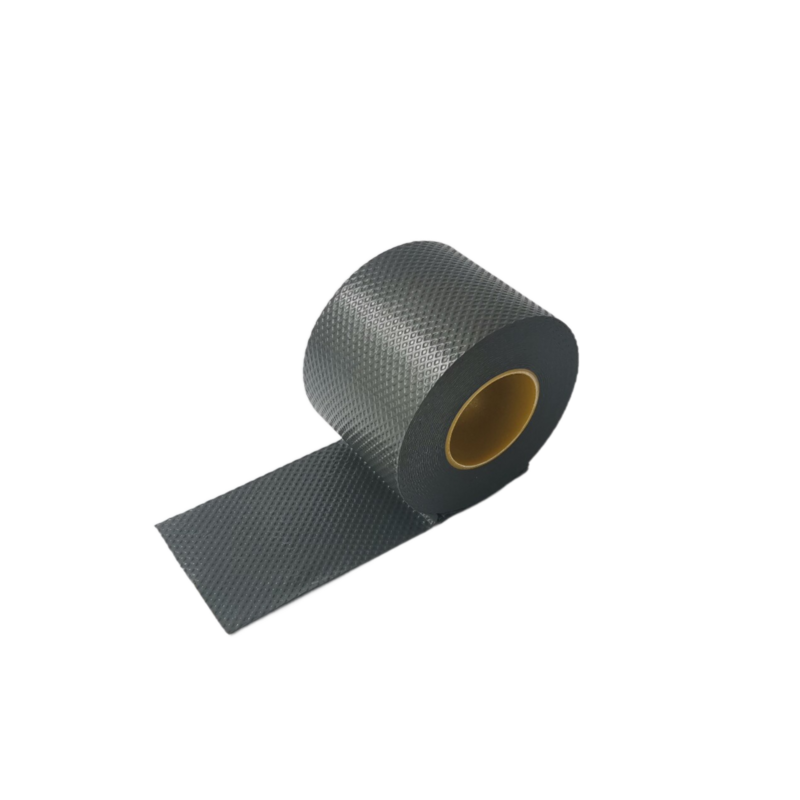

Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments

Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments rubber tape self fusing. Its dielectric properties also make it safe to use around electrical components, ensuring that your wiring job is both effective and safe.

rubber tape self fusing. Its dielectric properties also make it safe to use around electrical components, ensuring that your wiring job is both effective and safe.What is a control box?

The use of a vent or air handling units may be essential if the control box is situated in high atmospheric temperature area's. If temperature management is required, then air intakes and exhaust vents should be easily accessible so that filters may be accessed and replaced. Both the NEC and UL clearance requirements surrounding electrical wiring and heat-producing equipment must be considered.

2. Improved Organization A well-organized workspace leads to increased productivity. By utilizing floor marking tape to designate specific areas for equipment, inventory, and personnel movement, businesses can reduce clutter and confusion.

Repair Needs: Assess the nature and extent of your repair requirements. Each tape is best suited for different types of repairs.

flex tape 4 inch. The 4-inch size ensures that there is enough material to withstand the elements, whether exposed to sunlight, moisture, or temperature extremes. It resists aging, maintaining its stickiness and strength over time, which is critical for repairs that demand lasting solutions.

flex tape 4 inch. The 4-inch size ensures that there is enough material to withstand the elements, whether exposed to sunlight, moisture, or temperature extremes. It resists aging, maintaining its stickiness and strength over time, which is critical for repairs that demand lasting solutions.As we continue to seek effective and long-lasting solutions for everyday challenges, products like 3M Vulcanizing Tape remind us of the importance of quality in simplicity. When the need arises, this tape stands ready to provide a convenient, durable, and effective repair solution, reinforcing the idea that sometimes, the simplest tools can be the most powerful.

The primary difference between electrical and duct tape is their composition and material. Electrical tape is made from plastic vinyl or PVC, giving it a smooth and stretchy texture. Electrical tape is heat resistant and designed specifically for safely insulating electrical wires and materials that conduct electricity.

The benefits of butyl rubber rolls extend beyond their physical properties. Their long lifespan and low maintenance requirements make them a cost-effective solution for various industries. By reducing the need for frequent replacements or repairs, businesses can allocate resources more efficiently.

fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.

fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety. fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.

fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.The Versatility of Flex Tape A Comprehensive Review