quail farming cage design

Latest articles

Some welding methods of galvanized steel mesh will reduce the quality of low carbon steel welded joints, such as electroslag welding. Because the line energy is high, the coarse grains in the heat affected zone of welding will become very coarse, leading to a severe reduction in impact toughness. After welding, it is necessary to normalize with refined grains to improve impact toughness.

quail farming cage design...

quail farming cage design 【quail farming cage design】

Read More

quail farming cage designNow the production of stainless steel blade barbed rope unless it is a specially customized model, under normal circumstances are the use of a knife length of 22mm mold production, that is, we usually say bto-22 type. It’s not necessarily the case that there are specifications from 11mm to 65mm. Unless the customer insists on customizing the required length, the barbed rope manufacturer produces bto-22 stainless steel blade barbed rope.

...

quail farming cage design 【quail farming cage design】

Read Morequail farming cage design

...

quail farming cage design 【quail farming cage design】

Read More

quail farming cage design

Post time: 08-07-22...

quail farming cage design 【quail farming cage design】

Read More5, after the light plating should be carried out light treatment.

quail farming cage design...

quail farming cage design 【quail farming cage design】

Read More

quail farming cage designGalvanized wire coating is galvanized, aluminum plated, coated with nylon or plastic, etc. Zinc is divided into thin coating of steel wire after plating and thick coating of galvanized steel wire after drawing. The mechanical properties of thick coating are reduced compared with smooth steel wire rope, which should be used in severe corrosion environment. It is more resistant to corrosion, wear and heat than galvanized wire rope, using the first plating and then drawing method of production. Coated nylon or plastic wire rope is divided into two kinds of coated rope and coated stock after the rope.

...

quail farming cage design 【quail farming cage design】

Read Morequail farming cage design

...

quail farming cage design 【quail farming cage design】

Read More

quail farming cage design2. Adjust the drawing process parameters of the water tank

...

quail farming cage design 【quail farming cage design】

Read More

quail farming cage designAfter proper heat treatment or cold drawing hardening, high carbon steel wire has high strength and hardness, high elastic limit and fatigue limit (especially notched fatigue limit), cutting function is acceptable, but welding function and cold plastic deformation ability is poor.

...

quail farming cage design 【quail farming cage design】

Read Morequail farming cage design

...

quail farming cage design 【quail farming cage design】

Read More

Popular articles

- Reverse twist barbed rope: first wrap the barbed wire around the main wire (i.e. a single wire) and then add another wire to twist and weave it into a double strand barbed rope.

Post time: 15-11-22

Post time: 28-09-22- Pay attention to the maintenance of the dog cage, plastic and wire and other materials of the dog cage need to avoid exposure to the sun, the dog cage must be cleaned in time after cleaning with water, or rust will affect the service life.

Latest articles

Links

- To ensure the effective use of floor line marking tape, it is essential to follow best practices

- The importance of fire retardant duct tape becomes evident in emergency situations

- In conclusion, floor safety strips are an essential safety feature in any building or facility. By installing safety strips on slippery or wet surfaces, the risk of slips and falls can be greatly reduced, protecting employees, visitors, and customers from potential injuries. With their easy installation and minimal maintenance requirements, safety strips are a simple and cost-effective solution for improving safety and preventing accidents. Investing in floor safety strips is a smart choice for any business or organization looking to create a safe and secure environment for everyone.

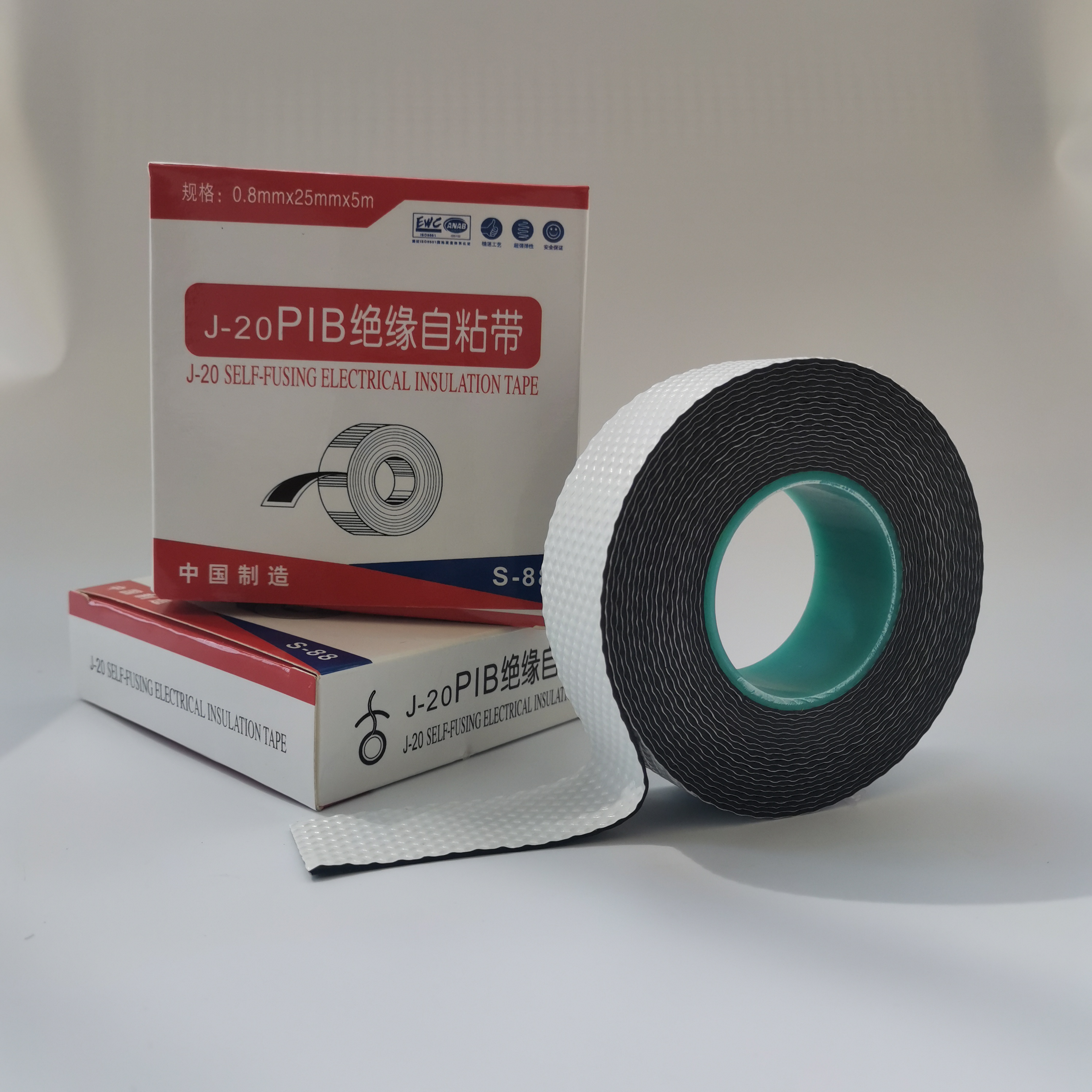

Linerless Insulating Rubber Tape

- One of the most common uses of rubber tape is in plumbing. When applied to the threads of pipe fittings, it creates a watertight seal, preventing leaks that can cause damage and inconvenience. Its thin and conformable nature enables it to penetrate into the smallest crevices, ensuring a secure seal even in tight spaces. The ease of application - simply winding the tape clockwise around the thread - makes it a favorite among DIY enthusiasts and professional plumbers alike.

These are typical control boxes designed to be installed on walls. This wall-mounted installation is preferred because it saves you space and makes it easier for you to access your box. Wall-mounted control boxes are commonly utilized in building systems, laboratories, and factory systems.

Compared to acrylic and rubber adhesives, they are significantly more expensive, but due to their excellent high temperature performance they are very well suited to splicing tapes, masking tapes and polyimide (Kapton) tapes.

Butyl weather stripping is made from a synthetic rubber compound known as butyl rubber. This material demonstrates impressive resistance to moisture, temperature fluctuations, and environmental factors, making it an ideal choice for sealing gaps around doors and windows. With an excellent lifespan, butyl weather stripping can effectively reduce energy loss, thus saving money on heating and cooling bills while increasing indoor comfort.

- In addition to its durability, self-vulcanizing tape is also flexible and stretchy. This allows it to conform to the shape of the object that you are repairing, ensuring a tight and secure fit. This flexibility also makes the tape easy to work with, as it can be wrapped around tight corners and odd shapes without issue.

Conclusion

butyl rubber tape uses.

Ensuring Your Control Box Meets Regulations

Product Variety:a wide range of options, allowing you to find the perfect tape for your specific needs.

Self-Fusing Silicone Electrical Tape A Versatile Solution for Electrical Insulation

4. Cost-Effective Solution Investing in premium butyl rubber tape is an economical choice. Compared to extensive repair work or replacing damaged materials, using butyl rubber tape to seal leaks can extend the life of existing structures. Regular maintenance with this tape can help prevent the occurrence of severe problems, leading to substantial savings in the long run.

In addition to its insulating properties, yellow tape is also useful for temporary markings. Electricians frequently work in environments where systems are being modified. In these situations, marking specific wires, circuits, or components temporarily can help maintain organization and ensure that everyone on site is aware of the current configuration. Whether it’s to indicate a wire that is to be rerouted or to label a circuit that is being serviced, the bright color of yellow tape offers high visibility, reducing the likelihood of accidental disconnections or mishaps.

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings