Safety and Hazard Marking

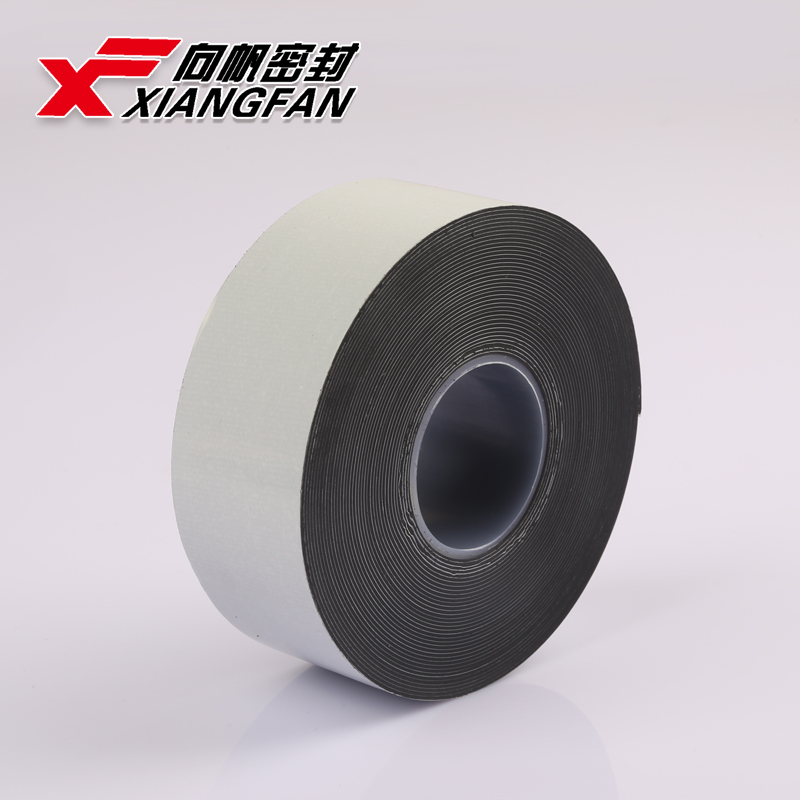

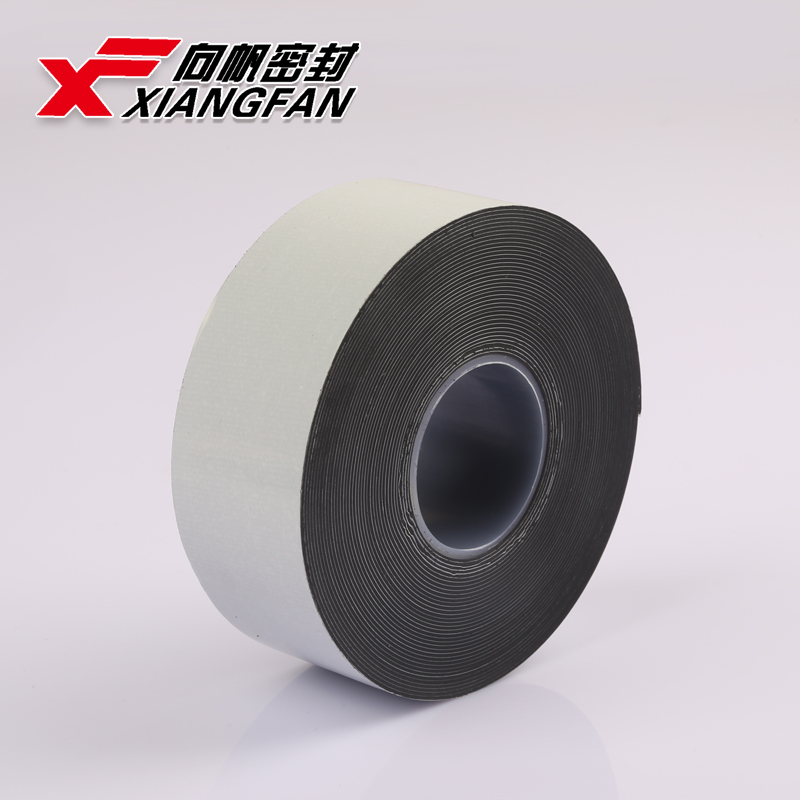

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials.

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials.Hot-dip galvanized wire is widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, electric power transmission, shipbuilding and other industries. It has been widely used in recent years in agricultural fields such as agricultural medicine sprinkler irrigation, greenhouse and construction industry such as water and gas transmission, wire casing, scaffolding, Bridges, highway guardrail and so on.

...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read More...

spiral barbed wire 【spiral barbed wire】

Read MoreHot dip galvanizing is dipped in zinc liquid melted by heating, with fast production speed and thick but uneven coating. The market allows a low thickness of 45 microns and a high of more than 300 microns. The color is dark, the consumption of zinc metal is much, the formation of infiltration layer with the matrix metal, the corrosion resistance is good, and the outdoor environment of hot dip galvanized can be maintained for decades. Application range of hot dip galvanizing: because the coating is thicker, hot dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for iron and steel parts in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, power transmission, shipbuilding and other industries, in the field of agriculture such as sprinkler irrigation, greenhouse and construction industry such as water and gas transmission, wire casing, scaffolding, Bridges, highway guardrail and other aspects, has been widely used.

This method is generally the use of hot rolled laminated plate as raw material, the annealed steel plate is first sent to the pickling workshop, with sulfuric acid or hydrochloric acid to remove the surface of the steel sheet oxygen hot galvanizing method. After pickling, the steel plate immediately enters the tank to soak and wait for galvanized, which can prevent the reoxidation of the steel plate. After pickling, water cleaning, squeeze dry, drying, into the zinc pot, the temperature has been maintained at 445-465℃.

Hard black galvanized iron wire is made of low carbon steel wire directly drawn by drawing machine. The primary characteristics of hard black galvanized iron wire are high hardness and bright appearance. Primary use for welding hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawn. The primary feature of soft black galvanized iron wire is good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving process, electric welding mesh, welding process products.

Steel wire and iron wire have many similarities, but carefully distinguish, will find that they are not only different in the material, but also in the product characteristics of the great difference. So when choosing, be sure to make a clear distinction between the two. Steel wire factory introduces steel wire carbon structural steel made above, generally not galvanized, used for machinery, spring. Black, very hard; Wire: made of mild steel (mild steel), galvanized, used for joining and binding. White and soft.

What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures

What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures expanding foam tape.

expanding foam tape.Material: Ethylene propylene rubber

If you’re working with live wires, for example, it’s always best to err on the side of caution and use heat-resistant tape instead.

Self-fusing rubber tape, also known as self-vulcanizing tape, is made from a specialized rubber material that adheres to itself when stretched and wrapped around an object. Unlike traditional tapes, which rely on adhesive to stick to surfaces, self-fusing tape bonds through a process called vulcanization. This means that when the tape is applied under tension, the molecules of the rubber intermingle and create a solid, impermeable layer that is both waterproof and electrically insulating.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

1. Enhanced Safety The primary benefit of floor marking tape is increased safety. By clearly marking hazardous areas, employees are less likely to wander into dangerous zones. This proactive approach helps prevent accidents and injuries.

PVC electrical tape and vinyl electrical tape are the two main types of cold-weather tape used for insulating wiring. The conditions in which they will be used may dictate which type you use as follows:

HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise

HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise black insulation tape price.

black insulation tape price.Safety and Hazard Marking

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials.

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials.Despite its many benefits, Flex Tape is not without its limitations. While it can be used to fix a wide range of issues, it is not a permanent solution and may need to be replaced periodically. It is also not recommended for use on flexible materials or surfaces that constantly move or bend, as it may not adhere properly.

Silicone tape is a double-sided, non-adhesive rubber tape that is:

5. Sustainability Practices