extra small wire dog crate

Latest articles

extra small wire dog crateIn order to pack and bundle galvanized wire on the surface of the deposit layer to remove the surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is caused by soaps and saponable fatty surfactants being brought into the tank. Moderate foam formation rates may be harmless. Small homogeneous particles of large denier present in the tank can stabilize the foam layer. To remove surface active substances by matting with activated carbon. Or filtration to make the foam less stable, which are effective measures; Other measures should also be taken to reduce the intake of surfactant. The electroplating speed can be significantly reduced by the introduction of organic matter. Although the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank.

...

extra small wire dog crate 【extra small wire dog crate】

Read Moreextra small wire dog crate

...

extra small wire dog crate 【extra small wire dog crate】

Read Moreextra small wire dog crate

...

extra small wire dog crate 【extra small wire dog crate】

Read More2. Drying: Dry the washed steel wire through hot air or other drying equipment to remove water.

extra small wire dog crate...

extra small wire dog crate 【extra small wire dog crate】

Read Moreextra small wire dog crate

...

extra small wire dog crate 【extra small wire dog crate】

Read More

extra small wire dog crateU-shaped nail price products:

...

extra small wire dog crate 【extra small wire dog crate】

Read MoreTechnical product wire, choose a wire special processing, no broken end, zinc amount uniform bright, general quotation slightly expensive. Galvanized silk also contains sprinkling: one plate per volume weight of about 100kg-1000 kg, mainly suitable for industry, agriculture, animal husbandry. Strong corrosion ability, solid coating and other characteristics.

extra small wire dog crate...

extra small wire dog crate 【extra small wire dog crate】

Read Moreextra small wire dog crate

...

extra small wire dog crate 【extra small wire dog crate】

Read Moreextra small wire dog crate

...

extra small wire dog crate 【extra small wire dog crate】

Read MoreIn addition to these reasons, we should also pay attention to the tooling and process must be stable, and regular testing should be done to ensure the uniformity of galvanized layer.

extra small wire dog crate...

extra small wire dog crate 【extra small wire dog crate】

Read More

Popular articles

- Galvanizing refers to the surface treatment technology of plating a layer of zinc on the surface of metal, alloy or other materials to play the role of aesthetics and rust prevention. The main method used now is hot galvanizing. However, hot dip galvanizing industry has been developed with the rapid development of cold strip rolling in the past 30 years. The production process of hot-galvanized sheet mainly includes: raw plate preparation → pre-plating treatment → hot-dip plating → post-plating treatment → finished product inspection and so on.

4. Keep the rinse water clean after pickling the steel wire

Latest articles

-

1. The diameter of raw materials and the thickness of the diameter have a direct impact;

-

-

In the purchase of large rolls of galvanized wire, see the hardness of galvanized wire first, only after the hardness reaches the standard can be used. The hardness standard of large roll galvanized wire is a very important performance index and an economic test method. But for the hardness of metal materials, there is not a unified and clear definition including all test methods at home and abroad.

-

Take the blade cord for example, the quality of the cord and the shape and direction of the surface barbs are what consumers need to consider. Professional materials in use can meet the needs of most consumers for materials, and the quality of these products is certainly to withstand the test, so if you really can not make up your mind, choose what kind of barbed rope, it is recommended to choose the best blade barbed rope.

-

-

Another notable application is in the realm of automotive repairs. Mechanics often use black PVC electrical tape to secure and insulate wire harnesses and connections in vehicles. Its high tensile strength ensures that it holds up well even in the harsh conditions found under the hood.

black pvc electrical tape

You can find content on insulating motor connections in web-based magazines, YouTube, and manufacturer websites. EC&M printed a good article on taping motor lugs a few years back. You can download it here. EC&M article download

One of the reasons Flex Tape is favored by many is its ease of use. Simply cut the desired length, peel off the backing, and apply it to the surface you want to repair. It requires no tools, and its flexibility means you can easily maneuver it into place, even in tight spots.

splicing tape use. This ensures a smooth and consistent print job without any breaks or interruptions. Similarly, in the packaging industry, splicing tape is used to join the ends of rolls of film or other packaging materials to create a continuous stream for packaging machines to work efficiently.

For instance, in construction sites, yellow tape may be used to outline areas that are off-limits or require special attention. In warehouses, it can signify pathways or areas where heavy machinery operates. By using yellow insulation tape, organizations can ensure that workers are aware of potential hazards, thereby reducing accidents and enhancing overall safety.

Heat and water-resistant

Silicone tape is renowned for its waterproof properties. It is an ideal solution for sealing leaks in boats, outdoor equipment, or even temporarily fixing damaged gutters during heavy rain.

Insulation tapes come in various specifications, which also impact their prices. Factors like tape thickness, width, and adhesion strength can make a considerable difference. For instance, thicker tapes typically offer better insulation and durability, which may justify a higher price. Some insulation tapes are designed for specific applications, such as high-voltage electrical work or outdoor exposure, and these specialized products often have a price tag to match.

emergency exit floor markings.

floor safety strips. They are easy to install and require minimal maintenance, making them a practical solution for reducing the risk of slips and falls. In addition to preventing accidents, safety strips can also help businesses comply with safety regulations and avoid costly liability claims.

Similar to its use in cars, butyl tape can also be a saviour in a motor home! While butyl tape is generally slightly more expensive than the usual putty tape used for RVs, the extra few dollars spent is worthwhile for a tape that doesn’t dry out as fast, is much easier to work with and isn’t as messy. Butyl tape is excellent for sealing motor home skylights.

By adhering to building codes and employing fire seal tape, builders and developers demonstrate their commitment to safety. Regular inspections and maintenance of fire seal tape can also ensure that it continues to perform its function throughout the life of the building.

Furthermore, PVC marking tape is highly durable and resistant to various environmental factors. It is often made from high-quality PVC material, which is known for its strength and flexibility. This ensures that the tape can withstand harsh conditions, such as exposure to moisture, UV rays, and chemicals, without deteriorating or losing its adhesion.

pvc marking tape

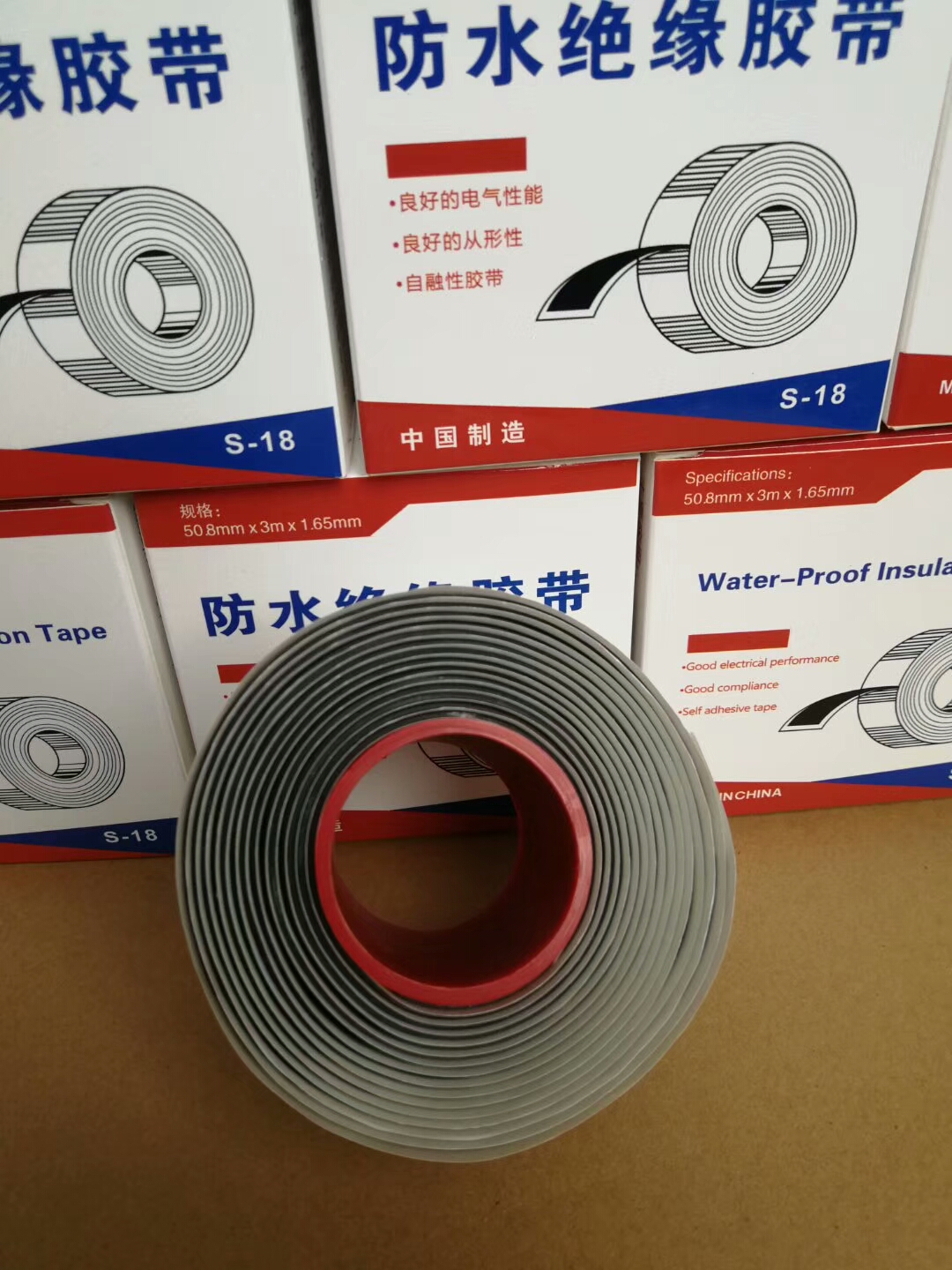

To use the tape, simply stretch it around the material you are trying to repair. As you wrap the tape in a circular motion, it begins to seal and “fuse” itself to the material. The most common forms of self-fusing / self-amalgamating tapes are made of silicone rubber (though other types also exist). They are designed to create a strong, seamless, rubbery, waterproof, and electrically insulating layer.

5. Allow the tape to cure Once wrapped, let the tape sit for a few minutes to allow it to cure and create a strong bond. Depending on the type of tape, it may take anywhere from a few minutes to a few hours to fully cure.

For best results, clear any debris or dirt away from the surface to which you’re applying the tape

industrial floor tape. This can help employees quickly locate necessary resources or navigate to safety in the event of an emergency. By using floor tape to clearly communicate important information, workplaces can enhance their overall safety and efficiency.