15 degree stainless steel coil siding nails

Latest articles

Pressure welded steel grid plate is the steel grid plate fixed by pressure resistance welding at each intersection of bearing flat steel and transverse bar, which is called pressure welded steel grid plate. Torsion torsion square steel is generally used for cross bar of pressure welded steel grid. Although they do not belong to the same variety, but in the steel lattice plate standards and performance are still the same.

15 degree stainless steel coil siding nails...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More5. It prevents your dog’s fear from causing chaos or other problems.

15 degree stainless steel coil siding nails...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More1. Choose according to the size of your dog

15 degree stainless steel coil siding nails...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

15 degree stainless steel coil siding nails

Post time: 26-12-22...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More15 degree stainless steel coil siding nails

...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

15 degree stainless steel coil siding nailsApplication: Mainly used in communication devices, medical equipment and braided mesh, brush, steel cable, filter screen, high pressure pipe, construction, technical products and other professional electric galvanized wire: is a low carbon steel as core wire, metal composite materials processed by wire drawing, electric galvanized technology.

...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

15 degree stainless steel coil siding nailsGalvanized iron wire can be divided into hot-dip galvanized iron wire and cold galvanized iron wire according to different processing methods. Galvanized iron wire is more prominent in its corrosion resistance. Galvanized iron wire has good toughness and elasticity, the amount of zinc can reach 300 g/square meter, with thick galvanized layer, strong corrosion resistance and other characteristics. Galvanized iron wire products are widely used in construction, handicrafts, wire mesh preparation, the production of galvanized hook mesh, wall mesh, highway guardrail, product packaging and daily civilian and other fields.

...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

15 degree stainless steel coil siding nails2. Stainless steel 316 material should be used in coastal areas, which can resist corrosion of sea water.

...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

15 degree stainless steel coil siding nails

Post time: 31-01-23...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

15 degree stainless steel coil siding nailsSteel mesh galvanized: galvanized refers to the surface of metal, alloy or other materials coated with a layer of zinc to play a beautiful, rust prevention and other surface disposal technology. Now the first choice of method is hot dip galvanized, galvanized solution has cyanide bath and cyanide-free bath two categories. Cyanide bath bisects micro cyanide, low cyanide, medium cyanide, and high cyanide.

...

15 degree stainless steel coil siding nails 【15 degree stainless steel coil siding nails】

Read More

Popular articles

Post time: 02-06-23- In use, it can be well used to control its soft and hard degree in the annealing process, mainly used in the construction industry as a binding wire and binding line. Of course, its use is not limited to arts and crafts, but also widely used in the construction industry. Earlier woven lanterns were made of iron wire with appropriate candles placed inside. People hung them in front of their doors and looked very beautiful at night.

Post time: 23-04-23

Latest articles

-

First, galvanizing can enhance the corrosion resistance of the product. Zinc has high potential and excellent anodic protection. When the surface of the product is galvanized, zinc will have an electrochemical reaction with oxygen and water in the environment, thereby forming a dense zinc oxide protective film, preventing the metal from further contact with external oxygen, water and other substances, slowing the corrosion rate of the metal. Galvanized products after wire drawing processing, because the surface of the product has a more dense zinc oxide protective film, it can better resist external corrosion and improve the corrosion resistance of the product.

-

Post time: 08-03-23 -

Uses of galvanized hexagonal net: building wall fixed, heat preservation, heat insulation; Power plant tie pipe, boiler warm; Anti-freezing, residential protection, landscaping protection; Raising chickens and ducks, isolating chicken and duck houses, plays a role in protecting poultry; To protect and support seawalls, hillsides, roads and Bridges and other waterworks.

-

-

Compared with the traditional braided and twisted barbed rope, the price of raw materials is relatively high because of the relatively complex technology.

-

First of all, we need to pay attention to the material of the barbed wire, because the galvanized barbed wire itself includes cold plating and hot plating. The properties and prices of the two are obviously different, and it is easy to be confused by a little negligence.

3. Automotive Emergency Repairs

- Home Improvement and DIY Projects For general repairs, home electrical systems, and protecting outdoor wiring.

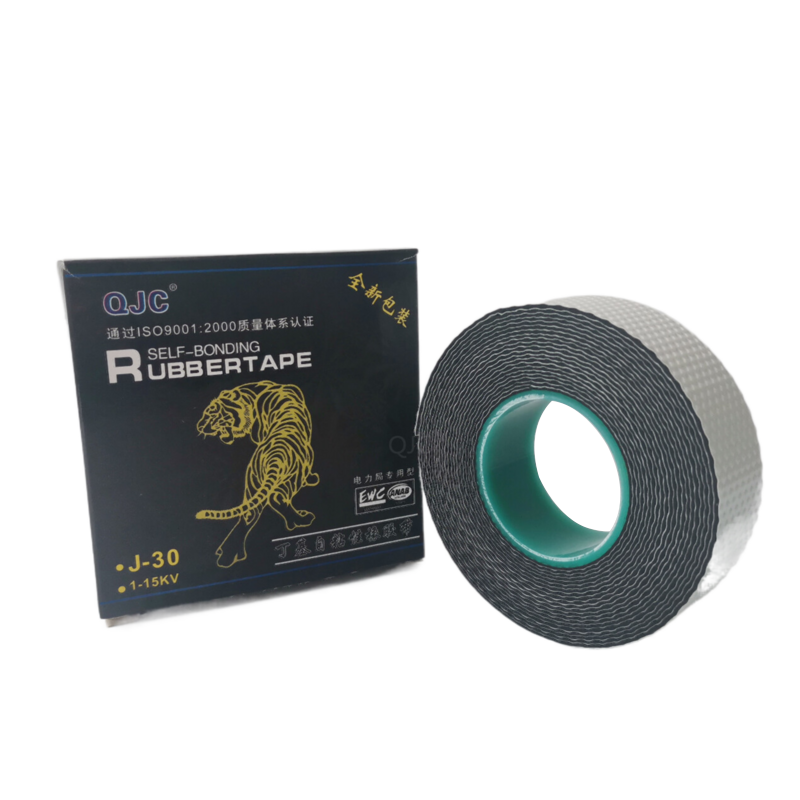

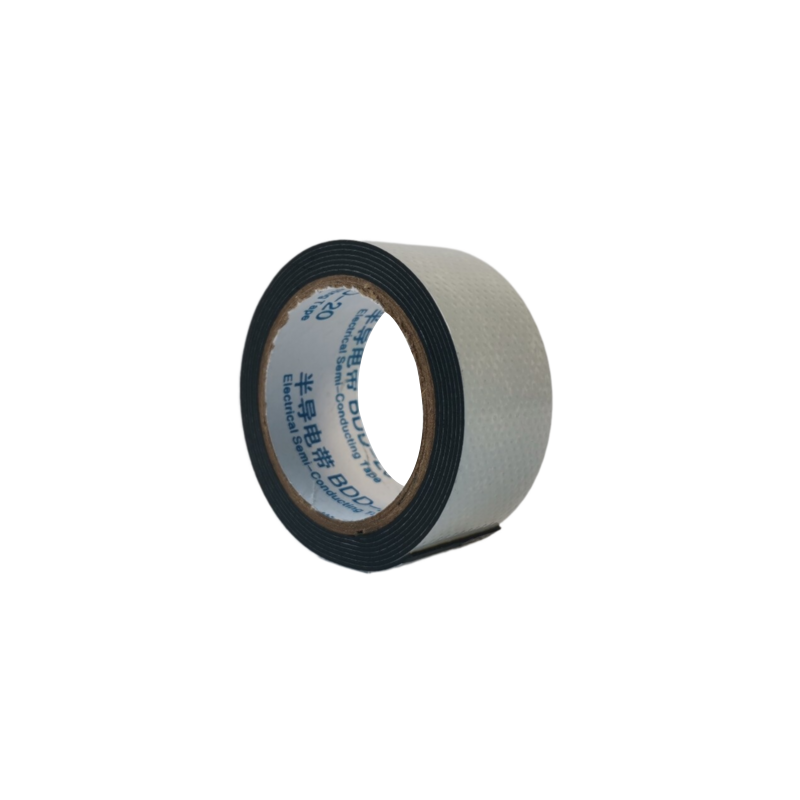

To use the tape, simply stretch it around the material you are trying to repair. As you wrap the tape in a circular motion, it begins to seal and “fuse” itself to the material. The most common forms of self-fusing / self-amalgamating tapes are made of silicone rubber (though other types also exist). They are designed to create a strong, seamless, rubbery, waterproof, and electrically insulating layer.

epr self amalgamating tape. It can also be used for sealing and repairing plumbing leaks, making it a handy tool to have in any toolbox. Additionally, the tape is chemically resistant, making it suitable for use in a variety of industrial settings.

Here are some specific things that control box can do:

Construction:In the construction industry, butyl sealant tape is widely used to seal joints, seams, and gaps in various building materials, such as roofing membranes, window frames, and metal panels.

flex tape black 4 in x 5 ft. Press down firmly to ensure a secure bond, and your repair is complete. There is no need for messy adhesives, complicated tools, or drying time – Flex Tape Black provides a quick and reliable solution to your repair needs.

high tension insulation tape. For instance, green indicates earth or ground, blue denotes neutral, while brown and black are commonly used for live conductors. This color coding not only enhances safety by visually differentiating wires but also streamlines installation and troubleshooting processes.

high tension insulation tape. For instance, green indicates earth or ground, blue denotes neutral, while brown and black are commonly used for live conductors. This color coding not only enhances safety by visually differentiating wires but also streamlines installation and troubleshooting processes.

waterproof door seal strip. A tight seal around the door prevents sound from traveling through the gaps, creating a quieter and more peaceful environment. This can be particularly beneficial for homes or buildings located in noisy neighborhoods or areas with high traffic.

Key Components of a Control Box

Not all butyl rubber tapes are created equal. Suppliers may offer various types of butyl rubber tape with different properties and qualities. When selecting a supplier, it is essential to ensure they offer a variety of products that meet specific project requirements. Look for tapes with certifications that confirm their quality standards, such as ISO or ASTM certifications. Quality materials will often reflect in the overall performance and durability of the tape.

butyl rubber tape supplier