perforated plate sizes

Latest articles

Ask the factory to provide the corresponding quality inspection report before packing. Cold drawing is a kind of material often used in our life, especially in the construction of buildings. Cold wire drawing is used more in building materials, cold wire drawing testing standards are also different. The strength of cold wire drawing is high, and it can be used in many aspects. Where plasticity is not required, only strength is required, such steel can be used.

perforated plate sizes...

perforated plate sizes 【perforated plate sizes】

Read More

perforated plate sizesPlastic spraying is also we often talk about electrostatic powder spraying, it is the use of electrostatic generator to make plastic powder charged, adsorption on the surface of the iron plate, and then through 180~220 DEG C baking, so that the powder melting adhesion on the metal surface, plastic spraying products are used for indoor use of the box, paint film flat or matte effect. Spray powder mainly acrylic powder, polyester powder, etc.

...

perforated plate sizes 【perforated plate sizes】

Read Moreperforated plate sizes

...

perforated plate sizes 【perforated plate sizes】

Read Moreperforated plate sizes

...

perforated plate sizes 【perforated plate sizes】

Read More

perforated plate sizes

Post time: 07-07-22...

perforated plate sizes 【perforated plate sizes】

Read More

perforated plate sizes

Post time: 01-09-22...

perforated plate sizes 【perforated plate sizes】

Read More

perforated plate sizes...

perforated plate sizes 【perforated plate sizes】

Read MoreAnd for the external insulation system is used in the brick veneer, as for the role of first should also be anti fall off followed by anti cracking, so should choose the grid 10×10×0.6, these are some experience choice, grid conversion from the national regulations of steel mesh specifications, using steel level conversion. The index of wire mesh size, wire warp, square meter steel content, galvanized amount, etc., mainly consider the corrosion resistance of wire mesh and the safety of the system! Galvanized wire mesh is more critical than wire diameter, galvanized amount is very important, must be hot plating, welding after plating is better than plating after welding, as for wire diameter, comprehensive consideration of site construction and to meet the needs of safety, 0.6 ~ 0.7 is better.

perforated plate sizes...

perforated plate sizes 【perforated plate sizes】

Read Moreperforated plate sizes

...

perforated plate sizes 【perforated plate sizes】

Read More1, we should pay attention to the welding mesh moisture-proof: if it is just the general outdoor air humidity, do not bother. If the weather is foggy, use dry cotton cloth to wipe the bead on the welding mesh; If it rains, you should dry the water when the rain stops. Try to maintain and prolong the life of the welding mesh.

perforated plate sizes...

perforated plate sizes 【perforated plate sizes】

Read More

Popular articles

Compared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. Because the coating obtained is thicker, hot-dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for steel parts used in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, ocean exploration, metal structure, electric power transmission, shipbuilding and other industries.

- 2. If the surface of the stainless steel pet cage is adhered to organic juice (such as melon, vegetable, noodle soup, phlegm, etc.), in the case of water and oxygen, it constitutes organic acids, and the corrosion of organic acids on the metal surface for a long time.

Features: Strong flexibility, good plasticity, a wide range of uses process: selection of high-quality low-carbon raw materials, after drawing, annealing processing, soft and strong tensile resistance. The finished product is coated with anti-rust oil, not easy to rust, can be bundled according to customer requirements, each bundle is 1-50kg, can also be made into U wire, broken wire, etc., plastic inside and linen outside packaging, mainly used for binding wire, construction wire, etc.

Latest articles

-

-

In the processing of stainless steel barbed wire after cold galvanized or hot galvanized coating on the surface of the last zinc material, not only beautiful but also plays a good protective role.

-

Hexagonal cage has a wide range of applications, with the progress of science and technology, has been extended to the major hydraulic engineering, civil engineering. Geotechnical engineering and other projects. In the hydraulic hexagonal cage in the river construction to reach the utility, that is appropriate and the use of hexagonal cage used to fill stone, fixed river, can be used to avoid river erosion bring water and soil loss. In the civil engineering project, the hexagonal cage is considered appropriate and the use of similar particle size volume particle filling, the mesh wall is formed between the cage, which is the stone cage mesh retaining wall.

-

5, according to the thickness of the wire diameter to adjust zinc dipping time

-

The form of installation: in the top with the various cage tied together at least as wrapped stone cage net that combination closely not easy to use bad. If the local bandaging is appropriate, it can increase the stability of the structure. There are a lot of grid edge, if the stone cage net only hook in the cage edge and not prepared in the cage edge, even in loose.

-

Three is to do a good job in the production site of galvanized wire products clean and tidy, according to the scientific operation method to operate the production, the operator should wear the required dress. If it is hot dip galvanized wire products, we must do a good job of passivation treatment, will be able to effectively prevent discoloration, prolong the method of discoloration, can solve the problem of discoloration.

Links

1. Labor Costs The wage of the operators who run the machines is a significant component. Skilled machinists who can effectively operate overlock machines may command higher wages due to their expertise.

In conclusion, long arm stitching machines offer a range of benefits that make them a valuable investment for sewers of all skill levels. With their spacious workspace, greater visibility, versatility, and advanced features, these machines make sewing and stitching easier, faster, and more enjoyable. If you're looking to upgrade your sewing equipment and take your projects to new heights, consider adding a long arm stitching machine to your collection.

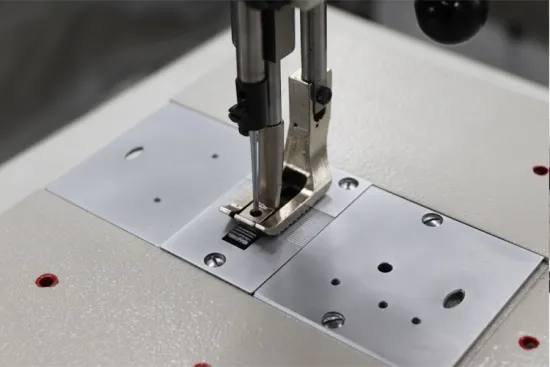

For quilting enthusiasts and professionals alike, a heavy-duty quilting sewing machine is an invaluable tool that makes the process of creating beautiful quilts more efficient and enjoyable. These machines are designed to handle thicker fabrics and multiple layers, providing the power and durability needed for heavy-duty sewing projects. In this article, we’ll explore the key features, benefits, and tips for selecting the perfect heavy-duty quilting sewing machine.

While double needle sewing machines offer numerous benefits, they can present a bit of a learning curve, especially for those new to sewing. The setup may require some practice, particularly when it comes to threading the machine and managing two threads simultaneously. However, many manufacturers provide comprehensive manuals and resources to help users navigate the initial challenges. Additionally, once familiar with the machine, users often find that the rewards far outweigh the initial hurdles.

Moreover, compound feed sewing machines are extensively used in garment manufacturing. They can easily handle multiple layers of fabric, which is crucial for creating garments that require precision and uniformity. Whether sewing intricate designs or constructing simple garments, these machines excel in delivering high-quality results.

- There are a few key factors to consider when selecting needles for upholstery sewing. The first factor to consider is the size of the needle. Needles come in various sizes, ranging from larger sizes for heavy-duty fabrics to smaller sizes for lighter weight materials. It's important to choose a needle size that is appropriate for the fabric you will be working with. Using the wrong size needle can result in skipped stitches or broken threads.

Another big factor is how much it will cost to purchase the device. Because the heavy-duty machine has been designed to do perform a wider range of tasks, it will tend to be more expensive. You might also be expected to pay higher electricity costs. This can be compared with a high-quality regular machine, that only costs a few hundred dollars to purchase and has much lower running costs.

4. New vs. Used Machines The market also offers the option of purchasing used double needle sewing machines, which can be a budget-friendly choice for those looking to save on costs. However, while used machines may come at a lower price point, buyers should be cautious about the condition of the machine, potential wear and tear, and whether it comes with a warranty. Investing in a new machine may provide more reliability and peace of mind.

One of the standout features of the lockstitch seam is its strength. The interlocking nature of the stitch creates solid seams that can withstand considerable strain, making them ideal for construction where durability is key, such as in sewing everyday clothing, bags, and upholstery. Additionally, the lockstitch lies flat against the fabric surface, which enhances the overall aesthetic appeal of the finished product.

Understanding the Price of Five Thread Overlock Machines

The activity of GSC367TD is also regulated by various signaling pathways within the cell. For example, certain signals can trigger the phosphorylation of GSC367TD, altering its ability to bind to DNA and regulate gene expression. In this way, GSC367TD can act as a molecular sensor, responding to changes in the cellular environment to modulate gene expression accordingly.

Furthermore, automatic quilting machines can also handle a variety of fabrics and materials with ease. Whether quilting cotton, silk, wool, or even thicker materials like denim, these machines are equipped to handle the job. This versatility allows for endless creative possibilities, as quilters can experiment with different fabrics and textures without worrying about the machine's capabilities.

Understanding Pattern Sewing Machine Prices

3. Bonded Thread Bonded threads are specially treated to withstand extreme conditions and are often used in industrial sewing. They have a protective coating that helps reduce friction and wear, making them ideal for high-stress applications.

Benefits of Using a Single Needle Edge Cutter Machine

Advantages

the cub leather sewing machine.

Applications in Leather Goods Production

Another consideration is the need for regular maintenance and updates to software, which can be an added expense. Companies must also ensure they keep abreast of technological advancements to maximize the capabilities of their machines over time.

4. Affordability Compared to motorized counterparts, hand crank sewing machines are often more affordable. This cost-effectiveness makes them accessible for beginners and those who want to explore the art of leather crafting without a hefty investment.

One of the primary advantages of using a 5% thread overlock machine is its ability to create durable seams. The overlocking stitch encases the raw edges of the fabric, thus preventing fraying. This is particularly important for those working with stretch fabrics, as a standard sewing machine may not provide the same level of support and flexibility.