1 4 wire screen

Latest articles

1 4 wire screen

...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screenElectric galvanized shaft wire direct selling is in the plating tank through the current unidirectional zinc gradually plated on the metal appearance, the production speed is slow, uniform coating, thin thickness, usually only 3-15 microns, bright appearance, poor corrosion resistance, generally a few months will rust. Compared with hot dip galvanizing, the production cost of electric galvanizing is lower. The difference between cold galvanizing and hot galvanizing: the difference between cold galvanizing and hot galvanizing is that the amount of zinc is different. They can be identified from the color. The color of cold galvanizing is shiny silver white with yellow. Hot dip galvanizing shiny white.

...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screenBecause the coastline is generally erected for protection, but often because of environmental factors lead to serious corrosion of the barbed rope lost its function. Stainless steel barbed rope is specially set up to prevent corrosion. Stainless steel barbed rope because the environmental requirements are not very high can be very good protection itself will not have a problem to extend the use of life, so that you can ensure safety.

...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screen

Post time: 05-06-23...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screen

Post time: 17-06-22...

1 4 wire screen 【1 4 wire screen】

Read More1 4 wire screen

...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screen

Post time: 28-09-22...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screen

Post time: 02-03-23...

1 4 wire screen 【1 4 wire screen】

Read MoreKnife width: 6 (mm)

1 4 wire screen...

1 4 wire screen 【1 4 wire screen】

Read More

1 4 wire screenGalvanized wire is processed from low carbon steel wire rod, after drawing forming, pickling rust removal, high temperature annealing, cooling and other processes. Galvanized wire is widely used. Electroplating temperature should be controlled at 30 to 50℃. Because the chloride ions in the bath are very corrosive, quartz glass heaters are generally used.

...

1 4 wire screen 【1 4 wire screen】

Read More

Popular articles

- There are many blade specifications, first of all there are three types: spiral type, straight line, spiral cross type. Different units, the strength of the protection of different rope models. The blade barbed wire is mainly made of low carbon steel wire and aluminum magnesium alloy wire by spraying and welding. The blade material of the blade barbed wire is attached to the core wire made of stainless steel wire with professional mechanical strength, so the blade barbed wire has the advantages of good strength and aging resistance.

Silk screen material can choose galvanized wire, stainless steel wire, copper wire, plastic coated wire, paint wire, etc., different materials used in different fields, such as construction, breeding, decoration, etc.

Plastic paint is often see way of electrostatic daub, can be fixed on the periphery of the barbed wire or iron wire board, requires two baidu after heat treatment, make plastic paint or powder coating adhesive on the wire plate, these are painted plastic razor wire is commonly used in indoor boxes, plastic paint surface look overall feeling is very good, strong adhesive force, at the same time is more durable, Coating processing does not take too long, mainly rust prevention and corrosion effect is quite good, much better than the general material.

- Pet cage has many types, and selective is bigger, pet cages are generally made of wire, with better coarse, then at the bottom with a wheel base, such a simple pet basket was made, in the wheel at the bottom of the mount is for the convenience of the mobile, a pet cages should also adapt to the location of the production in addition to a door, Convenient in pet feeding when more convenient.

- Because the coating obtained is thicker, hot-dip galvanizing has very good protective function than electric galvanizing, so it is an important maintenance coating for iron and steel parts in strict working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, electric power transportation, shipbuilding and other occupations. In the field of agriculture, such as pesticide irrigation, greenhouse and construction industry such as water and gas transportation, wire casing, scaffolding, Bridges, highway guardrail and other aspects, it has been widely used in these years.

Latest articles

-

Post time: 20-10-22 -

-

4, galvanized can be used zincate galvanized or chloride galvanized process, should use appropriate additives to meet the requirements of this standard coating.

-

4. Keep the rinse water clean after pickling the steel wire

-

The material of the electric welding net is black wire, galvanized wire and wire drawing. The mesh is 1 inch, 2/1 inch, 3/1 inch, 4/1 inch, 4/3 inch, 8/5 inch, etc. Different materials, different mesh, used in different places. Therefore, electric welding net is an indispensable building material in the construction industry.

-

Links

- Moreover, mine extension drill rods with improved thread designs and coatings have enhanced the drilling process

- Chemical storage

- Firstly, the type of jack hammer plays a crucial role in determining its price. There are two main types electric and pneumatic. Electric models are generally more affordable and easier to operate, but they may lack the raw power and durability of their pneumatic counterparts. Pneumatic jack hammers, fueled by compressed air, offer greater strength and longevity, which reflects in their higher price point.

- In the realm of water treatment technology, the Fiberglass Clarifier System stands as a testament to human ingenuity and commitment to environmental sustainability. This innovative system, primarily designed to purify and clarify water, has been making waves in various industries due to its efficiency and durability.

- In parallel with material improvements, design optimization played a critical role in enhancing drill rod performance

- The primary advantage of an air rock drill is its power-to-weight ratio. Despite their compact size, they pack a significant punch, capable of drilling through even the toughest rock formations with ease. The use of compressed air ensures a smooth and clean operation, reducing the chances of equipment damage and minimizing maintenance costs.

- Moreover, the future of gas rock drilling is intertwined with the ongoing energy transition. As the world moves towards cleaner energy sources, natural gas is often seen as a bridging fuel, reducing reliance on coal while renewable technologies mature. Gas rock drilling, therefore, continues to play a vital role in meeting energy demands until more sustainable alternatives become prevalent.

- Additionally, thread rod extensions are often used in the automotive industry to secure components together. For example, in the assembly of an engine, thread rod extensions can be used to connect various parts, ensuring that they are held securely in place during operation. This helps to prevent any movement or loosening of critical components, which could lead to mechanical failures or accidents.

Post time: Dec-21-2020- One of the standout features of CPVC FRP tanks is their exceptional durability. CPVC is known for its strength and resilience, making it an excellent material for withstanding the rigors of industrial environments. When combined with the strength and durability of FRP, these tanks are capable of withstanding extreme pressures and temperatures, making them an ideal choice for storing chemicals, solvents, and other hazardous materials.

- In addition, the manufacturing process of fiberglass tanks is environmentally friendly

- 2. Consider the Environment If you'll be drilling in a dusty or dirty environment, choose a drill with a dust collector or an air filter to reduce the risk of damage to sensitive equipment or injuries to workers.

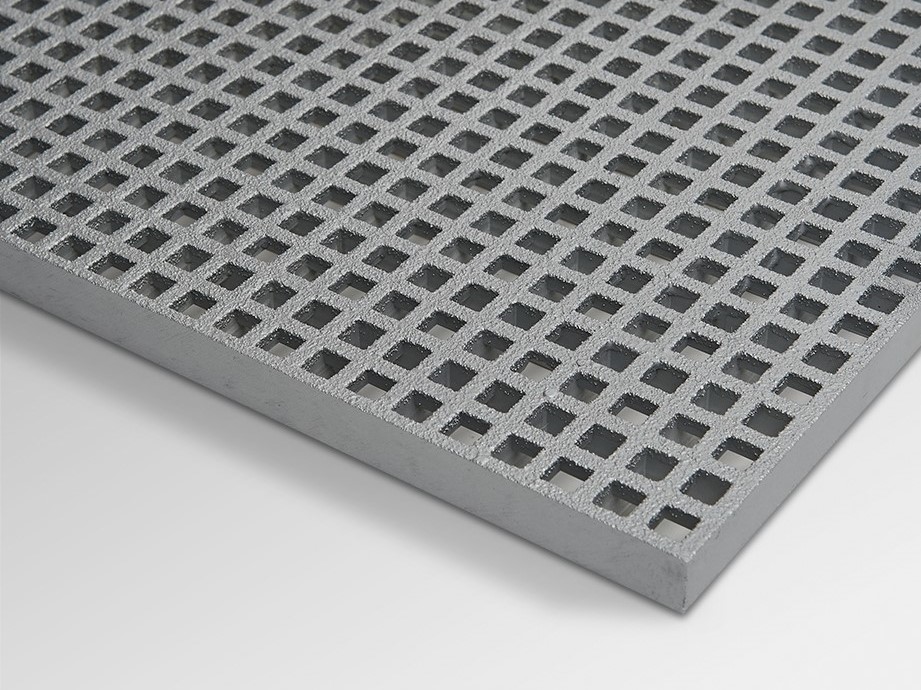

- Corrosion Resistant: FRP molded grating has good corrosion resistance, does not rust, and has a long service life, which reduces the cost of use, including life cost and maintenance cost.

Chemical Processing: Used in chemical plants and refineries due to its corrosion resistant and slip resistant properties.

These two sets of FRP launder systems adopted resin D411 and E fiberglass to resist the service medium and strength requirement.

Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating

Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating threaded rod drill bit.

threaded rod drill bit. fiberglass chemical tank. Their smooth, glossy surface is easy to clean and maintain, ensuring that they remain looking good even after years of use. And because they are available in a range of colors, they can be matched to existing equipment or branding schemes for a cohesive look.

fiberglass chemical tank. Their smooth, glossy surface is easy to clean and maintain, ensuring that they remain looking good even after years of use. And because they are available in a range of colors, they can be matched to existing equipment or branding schemes for a cohesive look. Because they are reusable and long-lasting, they can help reduce the amount of waste generated by disposable cleaning products Because they are reusable and long-lasting, they can help reduce the amount of waste generated by disposable cleaning products

Because they are reusable and long-lasting, they can help reduce the amount of waste generated by disposable cleaning products Because they are reusable and long-lasting, they can help reduce the amount of waste generated by disposable cleaning products fiberglass scrubber. This can have a positive impact on the environment and help reduce your carbon footprint.

fiberglass scrubber. This can have a positive impact on the environment and help reduce your carbon footprint.