rubber tape price. Well-known brands that have established a history of reliability and quality often charge premium prices. Their products usually undergo rigorous testing and come with better customer service and warranty policies.

rubber tape price. Well-known brands that have established a history of reliability and quality often charge premium prices. Their products usually undergo rigorous testing and come with better customer service and warranty policies.One of the key benefits of safety floor tape is its ability to improve traffic control and guide pedestrians and employees in the right direction. By using different colors and patterns, safety tape can be used to indicate walkways, restricted areas, emergency exits, or hazard zones. This helps to prevent confusion and ensure that people navigate the space safely and efficiently.

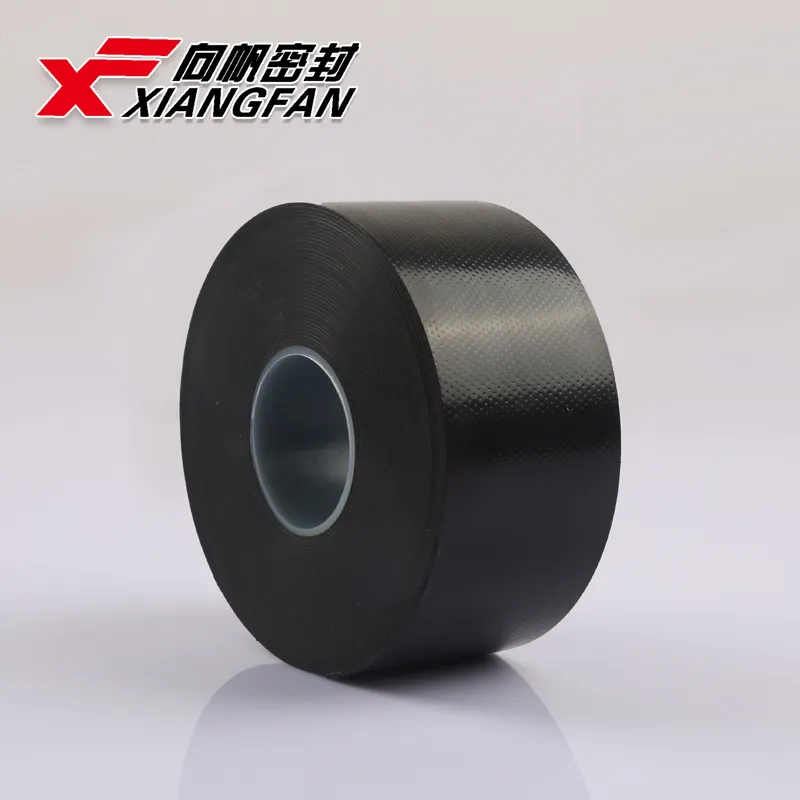

What Is A Self-Fusing Tape?

What Is A Self-Fusing Tape?