different types of building nails

Latest articles

different types of building nails

...

different types of building nails 【different types of building nails】

Read Moredifferent types of building nails

...

different types of building nails 【different types of building nails】

Read Moredifferent types of building nails

...

different types of building nails 【different types of building nails】

Read Moredifferent types of building nails

...

different types of building nails 【different types of building nails】

Read More

different types of building nailsWire mesh first welding after galvanized is through the end of welding and then the company to produce wire mesh wire mesh steel mesh construction mesh, floor heating mesh galvanized or hot dip galvanized. First galvanized after welding is to change wire mesh, after the end of welding can see the solder joint; The two processes are different in price. The cost of plating after welding is low, the appearance is smooth, and the cost of plating after welding is high, and it is not easy to rust.

...

different types of building nails 【different types of building nails】

Read More

different types of building nails

Post time: 07-04-23...

different types of building nails 【different types of building nails】

Read More

different types of building nails

Post time: 18-05-23...

different types of building nails 【different types of building nails】

Read MoreThe diameter of the wire is generally 0.3mm – 3mm, after the wire is not very strong, need to annealing, annealing this step is very important, can ensure the production of galvanized welding net, with good elasticity and toughness. After welding, the welding mesh becomes black wire welding mesh and can not be put on the market, because its corrosion resistance is poor and the service life is short, so it needs to be galvanized or dipped plastic treatment.

different types of building nails...

different types of building nails 【different types of building nails】

Read More

different types of building nailsGalvanized wire coating has galvanized, aluminum, nylon or plastic coating. Zinc plating is divided into thin coating after steel wire plating and thick coating after steel wire drawing. The mechanical properties of thick coating are lower than that of smooth steel wire rope, and it is suitable for use in serious corrosive environment. Aluminized wire rope it is more resistant to corrosion, wear resistance, heat resistance than galvanized wire rope, using the method of production after the first plating. The wire rope coated with nylon or plastic is divided into two kinds: coated rope and coated rope.

...

different types of building nails 【different types of building nails】

Read Moredifferent types of building nails

...

different types of building nails 【different types of building nails】

Read More

Popular articles

Latest articles

-

3, pay attention to the cage height

-

In order to pack and bundle galvanized wire on the surface of the deposit layer to remove the surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is caused by soaps and saponable fatty surfactants being brought into the tank. Moderate foam formation rates may be harmless. Small homogeneous particles of large denier present in the tank can stabilize the foam layer. To remove surface active substances by matting with activated carbon. Or filtration to make the foam less stable, which are effective measures; Other measures should also be taken to reduce the intake of surfactant. The electroplating speed can be significantly reduced by the introduction of organic matter. Although the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank.

-

-

3. Before cleaning the cage, put the birds in a safe place, and then clean out the garbage inside the cage. Clean it up with a sweep. Then use a wet rag to clean on site.

-

-

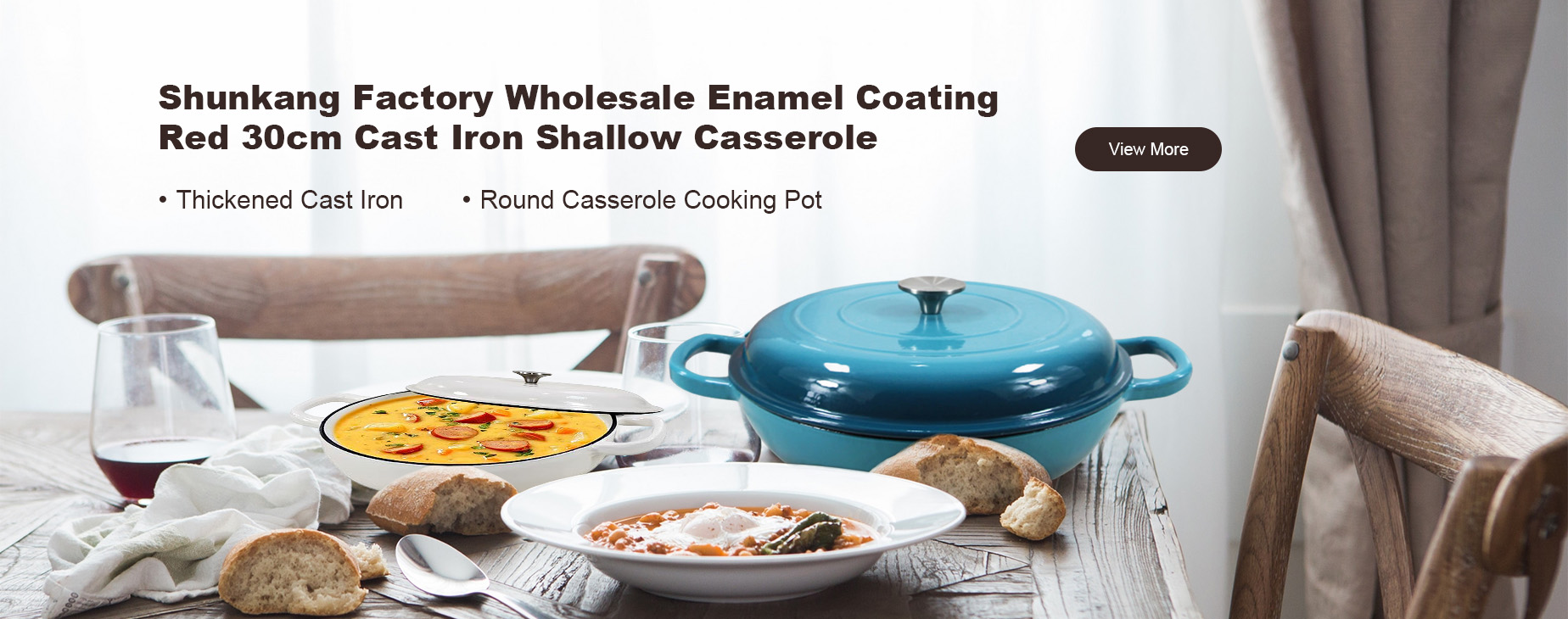

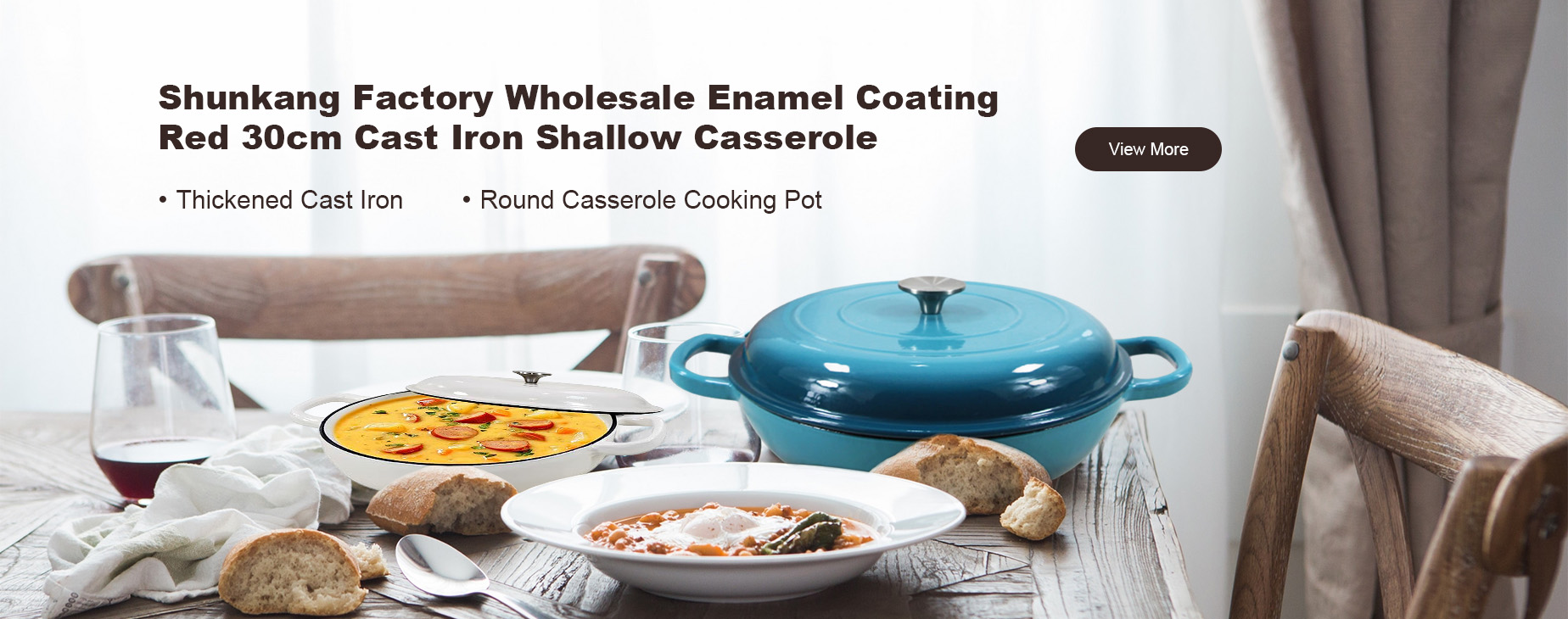

From carbon steel to enameled cast iron, we think almost every single kind of pan has its merits. But if you’re just getting into the home cooking game, or you’re looking to expand your toolkit, the sheer variety of pans on the market can feel intimidating—especially if you’re just looking for a good all-purpose pan for weeknight dinners.

enamel ware cookware.

One of the benefits of cast iron frying pans is that they are virtually indestructible. They can last a lifetime with proper care and can even be passed down from generation to generation.

cast iron flat top grill for stove. From juicy steaks to crisp vegetables, a cast iron flat top grill can handle it all with ease. Plus, the flat design of the grill makes it easy to flip and turn food, ensuring even cooking and delicious results every time.

Despite their attractive appearance, these skillets are robust enough to withstand high temperatures, transitioning seamlessly from stovetop to oven to tabletop Despite their attractive appearance, these skillets are robust enough to withstand high temperatures, transitioning seamlessly from stovetop to oven to tabletop

Despite their attractive appearance, these skillets are robust enough to withstand high temperatures, transitioning seamlessly from stovetop to oven to tabletop Despite their attractive appearance, these skillets are robust enough to withstand high temperatures, transitioning seamlessly from stovetop to oven to tabletop enamel coated cast iron skillet.

enamel coated cast iron skillet.Another thing to keep in mind when shopping for a pan is the amount of space you have available. If you have a farmhouse kitchen with ample drawer space and a pot rack, for example, you can justify picking up one (or more) of each. For more compact kitchens, however, a smaller multi-material set will allow you to do a lot with a little.

Flat bottom,Slope sides,No lids,Shallow depth.

Q:What are the disadvantages of using stainless steel frying pans?

A:The disadvantages of using stainless steel frying pans include their tendency to heat unevenly and their poor heat conductivity, which may require longer cooking times.

cast iron skillet cost. Heavier skillets tend to retain heat better, but they may also require more muscle to maneuver. The design, whether traditional or modern, can also influence the price, with some featuring ergonomic handles or unique shapes.

cast iron skillet cost. Heavier skillets tend to retain heat better, but they may also require more muscle to maneuver. The design, whether traditional or modern, can also influence the price, with some featuring ergonomic handles or unique shapes.Versatility and Culinary Capabilities:

Difference between stainless steel and non-stick cookware

Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests

Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests cast iron griddle.

cast iron griddle.Frying pans are usually made from various materials, including cast iron, stainless steel, aluminium, and copper. Each material has unique properties that make it suitable for specific types of cooking.

It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom

It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom big cast iron skillet.

big cast iron skillet.Stainless steel frying pans are also induction-ready. This means that they can be used on an induction cooker, which uses magnetic energy to heat the pan directly.