coated screen wire

Latest articles

coated screen wire

...

coated screen wire 【coated screen wire】

Read Morecoated screen wire

...

coated screen wire 【coated screen wire】

Read More

coated screen wireWith a large pickpocket used for steel wire, into the zinc liquid before the surface of the zinc ash stirring; Use a small outlet for galvanized steel wire; Zinc pot steel wire outlet in 30 minutes, with pickpockets back and forth, until the large, floating zinc residue into brown, real zinc ash, zinc ash surface. The extracted zinc ash should be brown yellow real zinc ash, zinc surface, effectively reduce zinc consumption. This is one of the biggest steps to bring zinc consumption down, and it’s a real problem, one that hasn’t been solved for years.

...

coated screen wire 【coated screen wire】

Read Morecoated screen wire

...

coated screen wire 【coated screen wire】

Read More

coated screen wireCommon galvanized iron wire equipment is usually used in barbecue net, barbecue net generally requires to have a long service life, with galvanized iron wire equipment to wire a layer of zinc, barbecue net is not easy to be corroded.

...

coated screen wire 【coated screen wire】

Read Morecoated screen wire

...

coated screen wire 【coated screen wire】

Read More

coated screen wire

Post time: 30-05-22...

coated screen wire 【coated screen wire】

Read More

coated screen wireOne is to do a good job of galvanized wire packaging, to avoid bumping, to ensure the integrity of the zinc layer;

...

coated screen wire 【coated screen wire】

Read Morecoated screen wire

...

coated screen wire 【coated screen wire】

Read MoreAlthough to be able to reduce the production cost, but the strength of the whole product will have a great lack of, so in this case will also let it have a great strength decline. Of course, in the shopping mall, the higher the intensity of the data in production, the higher the implementation of standards, naturally there will be certain progress in price.

coated screen wire...

coated screen wire 【coated screen wire】

Read More

Popular articles

- Professional materials in use can meet the needs of most consumers for materials, and the quality of these products is certainly to withstand the test, so if you really can not make up your mind, choose what kind of barbed rope, it is recommended to choose the best blade barbed rope.

- Three is to do a good job of galvanized silk product production site clean and tidy, in accordance with the scientific method of operation to operate the production, the operator should wear the required dress. If it is hot dip galvanized wire products, we must do a good job of passivation treatment, will be able to effectively prevent discoloration, prolong the method of discoloration, can solve the problem of discoloration.

Latest articles

Links

- In the realm of cooking essentials, few tools can match the versatility and durability of a well-crafted cast iron skillet. These timeless cookware pieces have been cherished by chefs and home cooks alike for generations due to their exceptional heat retention and ability to develop a natural, non-stick patina over time. In this article, we delve into the top 20 rated cast iron skillets that have earned their spots in kitchens worldwide.

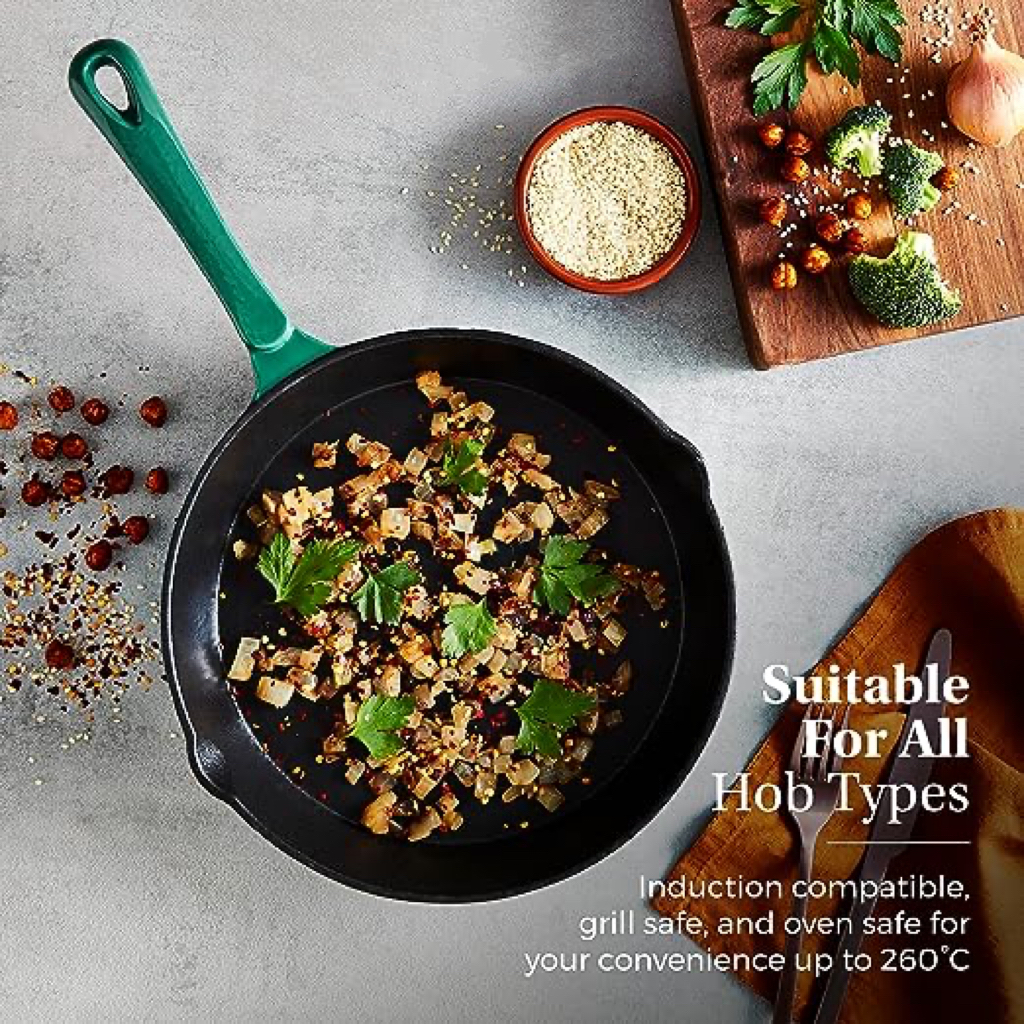

When it comes to cast iron skillet versatility, cast iron skillets stand out. cast iron skillet 's designed so that it can be used with a variety of heat sources, including stoves, ovens, grills, and even campfires. This means you can use cast iron skillet indoors or outdoors, making it a great choice for everyday cooking and outdoor adventures.

- In conclusion, investing in an iron skillet is an investment in timeless culinary tradition. Whether you choose a vintage find or a modern interpretation, each iron skillet holds the potential to create countless memorable meals. So, as you browse through the array of iron skillets for sale, remember to prioritize your cooking preferences, ergonomic needs, and aesthetic desires. With the right skillet in hand, you'll be well on your way to whipping up delicious, evenly-cooked dishes that will have your guests asking for seconds.

- Iron frying pans, often referred to as cast iron skillets, have been around since ancient times, originating from the ingenuity of early metallurgists. These pans are made by pouring molten iron into a mold, resulting in a thick, heavy, and robust cooking surface. The material's density is key to its ability to distribute heat evenly, ensuring a consistent cooking experience.

What Really Is The Difference Between A Skillet And A Frying Pan?

The depth of a frypan is usually more shallow than that of a skillet. This makes it more suitable for cooking food like steak, chicken breast, or stir-fried veggies. Its shallow depth also makes it ideal for food that requires frequent flips like frittatas, pancakes, eggs, and fish.

:max_bytes(150000):strip_icc():format(webp)/__opt__aboutcom__coeus__resources__content_migration__serious_eats__seriouseats.com__images__2014__06__20140701-skillet-flip-vicky-wasik-4-a83f7420d7954d14bd87fd3f4e0b890a.jpg)

Considerations:

Repairing Chipped Enamel Cookware Way

Stainless steel frying pans are also great for high-heat cooking and ideal for searing and browning food. They are also safe for use on all stovetops, including induction.

Not all pans are the same, however, and sometimes how your food turns out depends on what type of pan you use. Read on to see some of the most common types of frying pans and what they're used for.

The heavy-duty construction of the pot ensures that it retains heat well, allowing you to cook dishes that require long, slow cooking without burning or drying out The heavy-duty construction of the pot ensures that it retains heat well, allowing you to cook dishes that require long, slow cooking without burning or drying out

The heavy-duty construction of the pot ensures that it retains heat well, allowing you to cook dishes that require long, slow cooking without burning or drying out The heavy-duty construction of the pot ensures that it retains heat well, allowing you to cook dishes that require long, slow cooking without burning or drying out pre seasoned dutch oven. Whether you're making beef bourguignon, chicken pot pie, or even a batch of homemade bread, the pre-seasoned Dutch oven is sure to become your go-to cooking vessel.

pre seasoned dutch oven. Whether you're making beef bourguignon, chicken pot pie, or even a batch of homemade bread, the pre-seasoned Dutch oven is sure to become your go-to cooking vessel.Do chefs use non-stick cookware?

mini cast iron grill pan. Many such pans can be passed down through generations due to their long-lasting build quality, accumulating memories and flavors along the way. It's not uncommon for families to have a cherished cast iron pan that has been in use for decades, each grill mark telling a story of meals past.

mini cast iron grill pan. Many such pans can be passed down through generations due to their long-lasting build quality, accumulating memories and flavors along the way. It's not uncommon for families to have a cherished cast iron pan that has been in use for decades, each grill mark telling a story of meals past. classic cast iron skillet. It is a link to the past, evoking images of frontier cookouts, hearthside meals, and family recipes passed down through generations. Its weighty presence on the stove or in the oven is a reminder of the durability and resilience that characterized earlier eras.

classic cast iron skillet. It is a link to the past, evoking images of frontier cookouts, hearthside meals, and family recipes passed down through generations. Its weighty presence on the stove or in the oven is a reminder of the durability and resilience that characterized earlier eras.Durability and Longevity: Big black cast iron skillets are built to last a lifetime and beyond. With proper care and maintenance, they become seasoned over time, developing a natural non-stick surface that improves with use.

For small chips, epoxy repair kits designed for enamel and porcelain surfaces can be used. Clean the chipped area thoroughly, apply the epoxy according to the manufacturer's instructions, and carefully smooth the surface. Once the epoxy has dried, the repaired area should be sanded and polished to blend with the surrounding enamel.

A well-seasoned cast iron griddle forms a natural patina that prevents food from sticking, reducing the need for excess fats or oils during cooking A well-seasoned cast iron griddle forms a natural patina that prevents food from sticking, reducing the need for excess fats or oils during cooking

A well-seasoned cast iron griddle forms a natural patina that prevents food from sticking, reducing the need for excess fats or oils during cooking A well-seasoned cast iron griddle forms a natural patina that prevents food from sticking, reducing the need for excess fats or oils during cooking cast iron griddle for gas stove top. This not only makes cleaning up easier but also contributes to healthier meals.

cast iron griddle for gas stove top. This not only makes cleaning up easier but also contributes to healthier meals.