indoor pet cage

Latest articles

indoor pet cage

...

indoor pet cage 【indoor pet cage】

Read MoreWire mesh even in the mining industry also has a higher reflection, because the selection of low-carbon materials to do the material so that it has a general iron net class does not have flexibility, concluded that its plasticity in use, and then can be used in hardware crafts deep processing production, as the wall plastering, leak prevention crack and so on. Its light net body, lower cost, more can let customers experience its economic benefits.

indoor pet cage...

indoor pet cage 【indoor pet cage】

Read More2, galvanized silk mesh forming sheet storage ground should be flat, according to the symbolic needs of regular accumulation, height should not exceed 2M, and away from heat source, avoid exposure.

indoor pet cage...

indoor pet cage 【indoor pet cage】

Read Moreindoor pet cage

...

indoor pet cage 【indoor pet cage】

Read MoreIt is recommended to have a brush, comb or rake ready before bathing your dog; Shampoo, conditioner, shower gloves, tether, bath mat, floor drain lid, spray, towel and shower shower.

indoor pet cage...

indoor pet cage 【indoor pet cage】

Read More

indoor pet cage

Post time: 30-09-22...

indoor pet cage 【indoor pet cage】

Read More

indoor pet cageSecond: positive and negative twisting rope cost-effective

...

indoor pet cage 【indoor pet cage】

Read MoreCompared with the traditional braided barbed rope, the blade barbed rope has a relatively complex technology and a relatively high cost of raw materials.

indoor pet cage...

indoor pet cage 【indoor pet cage】

Read Moreindoor pet cage

...

indoor pet cage 【indoor pet cage】

Read Moreindoor pet cage

...

indoor pet cage 【indoor pet cage】

Read More

Popular articles

For the wide use of screen, the state has regulations. You also specify the diameter size, mesh size, or usage method. For plastering nets, the mesh should be less than 20 and the diameter should be greater than 1 mm. Not only are specifications specified, but safety is preferred if wire mesh is used in exterior plastering nets. If you fall, the consequences are unimaginable. Therefore, the application of norms should be combined with reality.

- Zinc pot workers should be determined to do duty and responsibility. Do not leave the post without leave, always observe the change of hot plating wire galvanized layer, and according to the analysis results, master the asbestos block gap friction, how long it takes to press, replace the pressing face; Adjust the working face; Until all four sides of the asbestos block are used up, maintenance workers will continue to use the block after repair when necessary to reduce the consumption of asbestos block.

The appearance quality of cold-drawn low carbon steel wire in each inspection lot shall be all visually inspected. The appearance of steel wire shall not have cracks, burrs, corrosion and mechanical damage affecting mechanical function. Cold-drawn low carbon steel wire with unqualified appearance can be used in engineering after treatment and inspection.

Latest articles

-

-

The welding process of galvanized steel wire mesh because of low carbon steel carbon content is low, manganese and silicon content is low, will not occur severe hardening or quenching structure due to welding. The low carbon steel joints have excellent plasticity and impact toughness after welding. In the welding process, it is generally not necessary to preheat, interlayer temperature control, post-heating control and heat treatment to improve the welding structure.

-

-

5. It prevents your dog’s fear from causing chaos or other problems.

-

-

Links

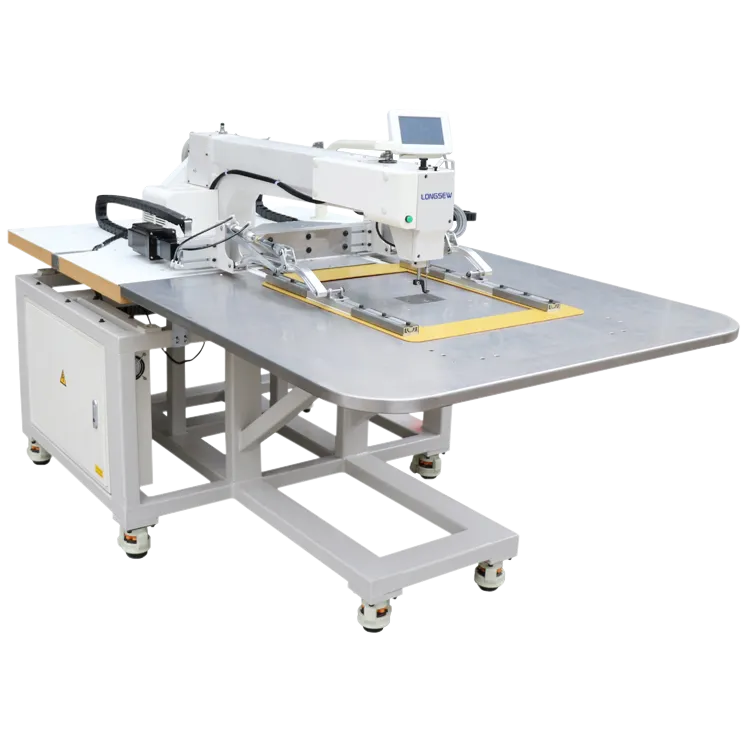

What is a Two Needle Embroidery Machine?

- The Art of Chain Lock Stitch A Tapestry of Enduring Craftsmanship

- Features Look for features that enhance functionality, such as differential feed for handling stretchy fabrics, adjustable presser foot pressure, and ease of threading. Some modern models also come with built-in cutting blades and a free arm for easier access to hard-to-reach areas.

Moreover, needle feed sewing machines often come equipped with advanced technology, such as programmable sewing patterns, automatic thread cutting, and adjustable stitch lengths. These features not only increase productivity but also allow for greater customization and precision in sewing tasks.