steel weld mesh panels

Latest articles

steel weld mesh panels

...

steel weld mesh panels 【steel weld mesh panels】

Read More

steel weld mesh panelsHexagonal mesh is made of galvanized iron wire woven by automatic mesh machine, mesh into regular hexagonal shape, mesh standard, beautiful, mesh size can be customized according to customer requirements, usually 27mm,20mm, 13mm, wire diameter from 0.40mm to 1.20mm, to meet the requirements of different customers.

...

steel weld mesh panels 【steel weld mesh panels】

Read More

steel weld mesh panelsCold galvanizing, also called electric galvanizing, is the use of electrolytic equipment to remove oil, pickling, after the pipe fitting into the composition of zinc salt solution, and connected to the negative electrode of the electrolytic equipment. Wire factory on the opposite side of the pipe fittings placed zinc plate, connected to the positive electrode of the electrolytic equipment is connected to the power supply, the use of current from the positive electrode to the negative electrode will deposit a layer of zinc on the pipe fittings, cold plating pipe fittings is first processed after galvanized.

...

steel weld mesh panels 【steel weld mesh panels】

Read Moresteel weld mesh panels

...

steel weld mesh panels 【steel weld mesh panels】

Read More

steel weld mesh panelsMaterial: galvanized silk

...

steel weld mesh panels 【steel weld mesh panels】

Read More

steel weld mesh panelsGuardrail in the purchase of how to install the correct is very important, and the installation of guardrail is important, the requirements of height and material are very strict.

...

steel weld mesh panels 【steel weld mesh panels】

Read Moresteel weld mesh panels

...

steel weld mesh panels 【steel weld mesh panels】

Read Moresteel weld mesh panels

...

steel weld mesh panels 【steel weld mesh panels】

Read MoreIn addition, galvanized silk manufacturers can be required to passivation treatment after zinc immersion, after passivation treatment of zinc has a better anti-discoloration effect, can effectively extend the time of discoloration, the combination of the two, discoloration should be able to solve.

steel weld mesh panels...

steel weld mesh panels 【steel weld mesh panels】

Read Moresteel weld mesh panels

...

steel weld mesh panels 【steel weld mesh panels】

Read More

Popular articles

The galvanized layer forms a particular metallurgical structure that is capable of accepting mechanical damage during transport and use. Every part of the plating can be zinc plated, even in dents, sharp corners and hidden places can be fully maintained. The galvanizing process is more convenient than other coating construction methods, and can avoid the required time after the installation on the site.

Post time: 02-09-22To remove surface active substances by matting with activated carbon. Or filtration to make the foam less stable, which are effective measures; Other measures should also be taken to reduce the amount of surface-active substances brought in to Z. The electroplating speed can be significantly reduced by the introduction of organic matter. Although the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank.

- If adult dogs touch noses with puppies out of affection, adult dogs touch noses with dogs that have more meaning in life. For example, dogs can touch their noses to communicate where food is safe and whether people or other animals are in danger.

Latest articles

-

Flexibility because the wire is different from other stainless steel raw materials, it is low density so in the flexibility of the appropriate excellent, it can be described according to people’s fantasy into all kinds of different shapes. Some large enterprises will buy hook flower net products, its reasons are no more than two, one is to prevent people outside the enterprise to walk around at will, the second is to advance the whole image of the enterprise. Therefore, under the premise that the protection requirements are not high, galvanized hook net can play a role in its use, the appearance of flexible hook net is settled to the use of address, from a distance and look at it like a work of art quite appreciate the meaning.

-

Post time: 25-07-22 -

-

-

-

For those who enjoy seasonal crafting, gold wire is an excellent choice for creating holiday decorations. From elegant ornaments to lush garlands, the shimmering finish adds a festive touch to winter decorations. It can also be used to create unique gift wrapping accents, such as bows or decorative ties, to enhance the visual appeal of presents and add a personal touch.

Дар хулоса, сими сафед василаест, ки бо ин ки ҳамеша дар даст дер шакл мегирад, вале имкониятҳои эҷодии бесаросамон ба таъсири он вусъат мебахшад. Ҳунармандони дасти мо бо истифода аз ин сим, қарор ёфта метавонанд, ки ҳар яки мо дар оянда ҳаракат намоем, дар шодии хонаи худамон ва ҳамагонро хурсанд кунем.

Machined springs’ coil slots are often too small to pass shot. Hence, shot peening is not common. Fatigue resistance often comes from stress relief holes and slots added to the slot ends. You can also select high strength, fatigue-resistant materials.

3. Security If security is your top priority, a chain link fence offers a formidable barrier against intruders. While it may not provide the same privacy as a solid wood or vinyl fence, its height and material make it difficult to breach. Additionally, you can enhance its security features with barbed wire or privacy slats, providing an extra layer of protection for your property.

Підсумовуючи, yard signs — це не просто елемент виборчої кампанії, а важливий фактор, який може суттєво вплинути на результат виборів. Вони формують громадську думку, підтримують активність виборців і підвищують видимість кандидатів. У світлі цих аспектів їх значення в українському контексті не можна недооцінювати.

Аднак садовая дрот – гэта не толькі практычны элемент агародніцтва. Яна таксама можа быць выкарыстана як творчы матэрыял для стварэння розных дэкаратыўных элементаў. Садоўнікі ўсё часцей ўжываюць яе для стварэння арок, шпалераў і іншых структур, якія не толькі падтрымліваюць расліны, але і фарбуюць сад у новыя колеры. Стальная дрот ідэальна падыходзіць для фарміравання розных фігур і геаметрычных узораў, што робіць сад яшчэ больш унікальным.

steel garden wire

Here is a quick overview of the process of designing a custom spring.

Tension and extension coil springs of a given material, wire diameter and coil diameter exert the same force when fully loaded; increased number of coils merely (linearly) increases free length and compressed/extended length.

Moreover, bamboo tomato cages are not only functional but also aesthetically pleasing. The natural color and texture of bamboo blend seamlessly into most garden settings, enhancing the overall appeal of your home landscape. After the growing season, these cages can be easily disassembled and stored, ready to be reused in future gardening endeavors.

Металевыя шыльды і іх значэнне

When it comes to gardening, few plants are as beloved and versatile as the tomato. From fresh salads to hearty sauces, tomatoes are a staple in many kitchens around the world. However, growing tomato plants can sometimes be challenging due to their tendency to sprawl, resulting in broken stems and spoiled fruit. One effective solution to this problem is the use of tomato cages. In this article, we’ll explore the significance of using these structures, particularly focusing on the concept of 5% tomato cages in terms of their impact on plant growth and gardening practices.

Mild steel weld mesh, a commonly used material in construction and various industrial applications, is known for its strength, versatility, and cost-effectiveness. This type of welded wire mesh is made from mild steel wires that are electrically welded at their intersections, forming a grid-like pattern. The result is a resilient and durable product that offers a multitude of uses across different sectors.

Our spring technicians then develop a new coil spring design using the most advanced spring software programme - Optispring. Plus, we book a feedback session with you to evaluate the success of the design.

For professionelle indrettere og butiksejere er disse paneler også en attraktiv mulighed for visuel merchandising. De giver en fleksibel måde at præsentere produkter på, hvilket gør det nemt at ændre udseendet af et display baseret på sæson eller kampagne. Den åbne struktur af wire grid’en lader varerne ånde, hvilket skaber en indbydende atmosfære for kunderne.

У сучасным свеце, дзе інфармацыя распаўсюджваецца з вялікай хуткасцю, важна мець магчымасць прадстаўляць свае ідэі і прадукты у наглядны і прафесійны спосаб. Металевыя шыльды, асабліва ў форме шыльдазімальнікаў, з'яўляюцца адным з найлепшых рашэнняў для гэтай мэты.

커스텀 제작 코일 스프링에 대한 이해코일 스프링은 기계 및 차량 산업에서 필수적인 부품 중 하나로, 힘과 에너지를 저장하고 전달하는 역할을 합니다. 기본적으로 스프링은 금속 재질로 만들어지며, 다양한 형태와 크기로 제작될 수 있습니다. 특히 커스텀 제작된 코일 스프링은 특정 용도나 요구에 맞추어 설계되기 때문에 그 중요성이 더욱 커집니다.커스텀 코일 스프링의 제작 과정은 여러 단계로 나누어지며, 첫 단계는 고객의 요구 사항을 이해하는 것입니다. 고객이 원하는 스프링의 용도, 강도, 길이 및 지름 등의 세부 사항이 모두 설계에 반영되어야 합니다. 이후 적합한 재료를 선택하고, 스프링의 형상을 계산하여 디자인을 완료합니다.제작 과정에서 스프링의 성능을 극대화하기 위해 여러 가지 공정이 필요합니다. 예를 들어, 열처리 과정을 통해 스프링의 강도를 높이거나 피복 처리를 통해 부식에 견디도록 할 수 있습니다. 이러한 과정을 통해 고객이 필요로 하는 성능을 갖춘 스프링을 제공할 수 있습니다.커스텀 코일 스프링은 자동차, 가전 제품, 기계 장비 등 다양한 분야에서 사용됩니다. 자동차의 서스펜션 시스템에서는 도로의 충격을 흡수하고 승차감을 개선하는 데 중요한 역할을 합니다. 또한, 가전 제품에서는 진동을 줄이거나 안정성을 높이는 데 도움을 줍니다.마지막으로, 커스텀 제작 코일 스프링은 고객의 특수한 요구에 부합하는 솔루션을 제공함으로써 제품의 경쟁력을 높이는 데 기여합니다. 따라서 신뢰할 수 있는 제조업체와 협력하여 최상의 품질과 성능을 보장받는 것이 중요합니다. 코일 스프링의 성능이 전체 시스템의 안정성과 효율성에 직결되기 때문에, 사전 설계와 충분한 테스트가 필수적입니다. 이러한 맞춤형 솔루션을 통해 고객의 다양한 필요를 충족시킬 수 있습니다.

custom made coil springs

In conclusion, masonry ties are indispensable in modern construction, providing vital support and stability to masonry structures. By understanding their functions, types, and proper installation techniques, builders can enhance the longevity and safety of their projects, ultimately ensuring that buildings can withstand both natural and human-induced stresses. As the field of architecture continues to evolve, so does the importance of masonry ties in creating resilient and sustainable environments.

Sıkıştırma yayları, otomotiv endüstrisinde yaygın olarak kullanılır. Örneğin, süspansiyon sistemlerinde, motor bileşenlerinde ve fren sistemlerinde kritik bir rol oynamaktadır. Ayrıca, inşaat ve makine sektörlerinde de yaylar, çeşitli makinelerin ve aletlerin işlevlerini desteklemek için kullanılır. Bunun dışında, tüketici elektroniği ürünlerinde, oyuncaklarda ve beyaz eşyada bile sıkça yer almaktadır.

នៅចុងបញ្ចប់ សារល្អប្រសើរលើភាពមិនធម្មតាដែលហូហួរៗជាច្រើនគួរត្រូវបានការោត្ថាាំរន្ធថាប្រសិនបើវាត្រូវបានជួសជុលនៅក្នុងពេលក្រោយ ព្រោះវាបានបញ្ជាក់ថាក្រុមហ៊ុនឧស្សាហកម្មអាចមានសំណង់ការសម្រេចគំនិតថ្មីៗដើម្បីជួយរក្សាឬបន្ថយពីតំបន់មួយទៅមួយហើយក្នុងនាមជាញឹកញាប់ផងដែរ។

When springs are used in mechanical operations, it is extremely important to know how they will react to certain weights and pressures. Custom compression springs, for example, contain a specific amount of energy when they are extended (in an at-rest position) to resist a certain amount of force. Their performance is measurable and predictable, given the types of material used. This makes it much easier to determine what springs to use in different applications, and exactly how often they can be used before they start losing strength.

Security Features

Compression springs possess several defining characteristics that make them uniquely suited for their diverse range of applications. These characteristics include:

Applications of light duty extension springs are diverse and encompass various industries. In the automotive industry, they are commonly used in seat mechanisms, tailgates, and trunk lids, where they assist in opening and closing functions. In the household sector, light duty extension springs are found in items like window blinds, retractable awnings, and various appliances, contributing to ease of use and functionality.

MBHD Carbon Steel: Medium basic carbon cold drawn spring wire per ASTM 227, suitable for parts subjected to average stress and applications; also suited to static orvery low cycles

Music Wire: Spring wire, per ASTM-228, good for parts subjected to high stresses and requiring good thermal properties. For temperatures up to 250°F

Type 302/304 Stainless Steel: Springs are manufactured to meet ASTM-A313, a high quality wire. For temperatures up to 550°F. Slightly magnetic. It is the most widelyused stainless spring wire because of high corrosion resistance properties and good tensile strength.

Black Oxide Coating (good) or Zinc Plating (better):improves the corrosion resistance of HDMB Carbon Steel and Music Wire

Passivation:an acid treatment performed on Stainless Steel Wire to remove contaminants and improve corrosion resistance

Nickel-coated Stainless Steel Springs: made from Suzuki™ Wire®, Nippon-Seisen wire and Sumiden® Type 302 nickel-coated stainless steel for superior corrosionresistance particularly in marine environments. Nickel plating is used in electronics because it provides a good surface for soldering, prevents tarnishing, and conductselectricity well.

A: The best approach is to consult with a spring manufacturer or an engineer. They can help you consider all the variables, including load, environmental conditions, and space constraints, to select the perfect spring for your project.

Machined springs are different. The flexure—the section providing the desired elasticity—is captive between the end sections, which provides structure and attachment. The end sections have infinite stiffness when compared to the flexure. Furthermore, the slots do not taper to zero at the ends; they remain at the full or initial width, as seen at free length. Thus, to achieve the same elastic performance, machined springs likely need to be longer than wire ones.

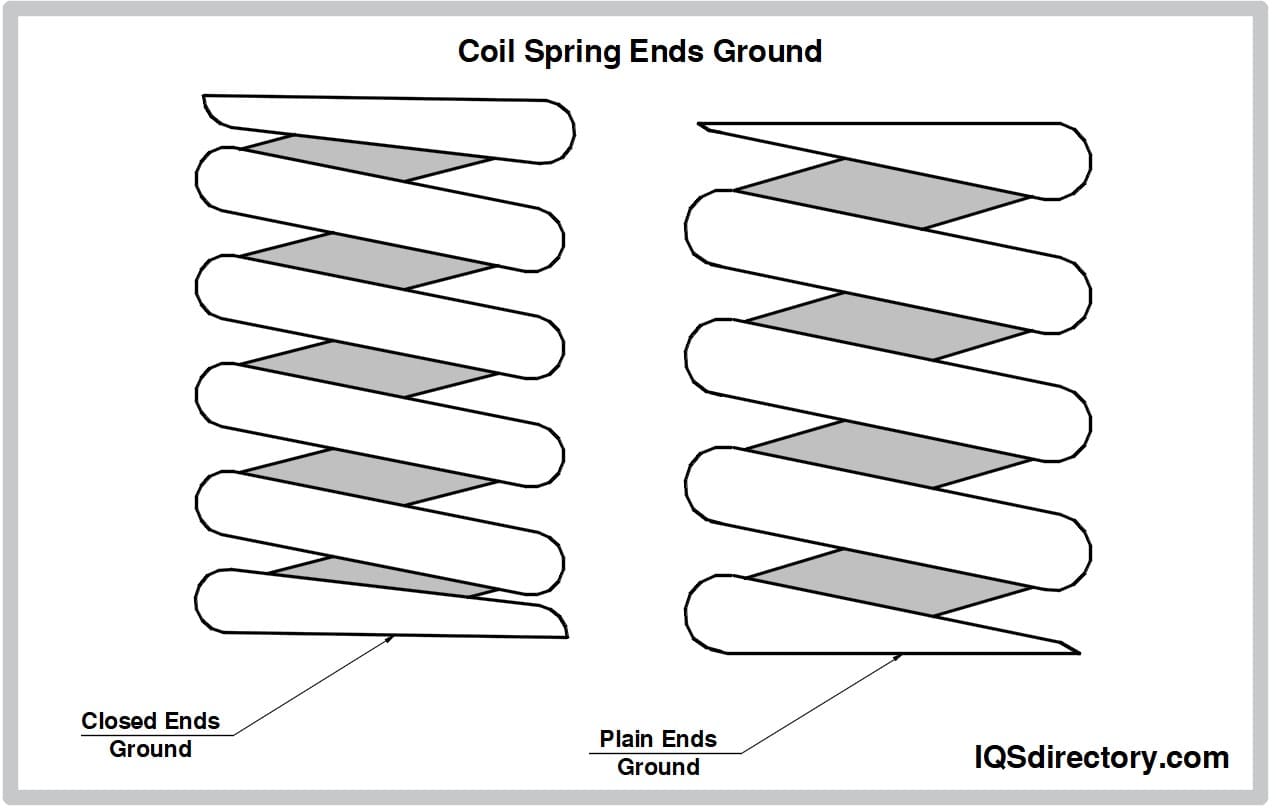

Grinding is frequently necessary to ensure the spring fits properly into its application and can sit flat. This process allows the spring to be positioned upright as required.

Applications

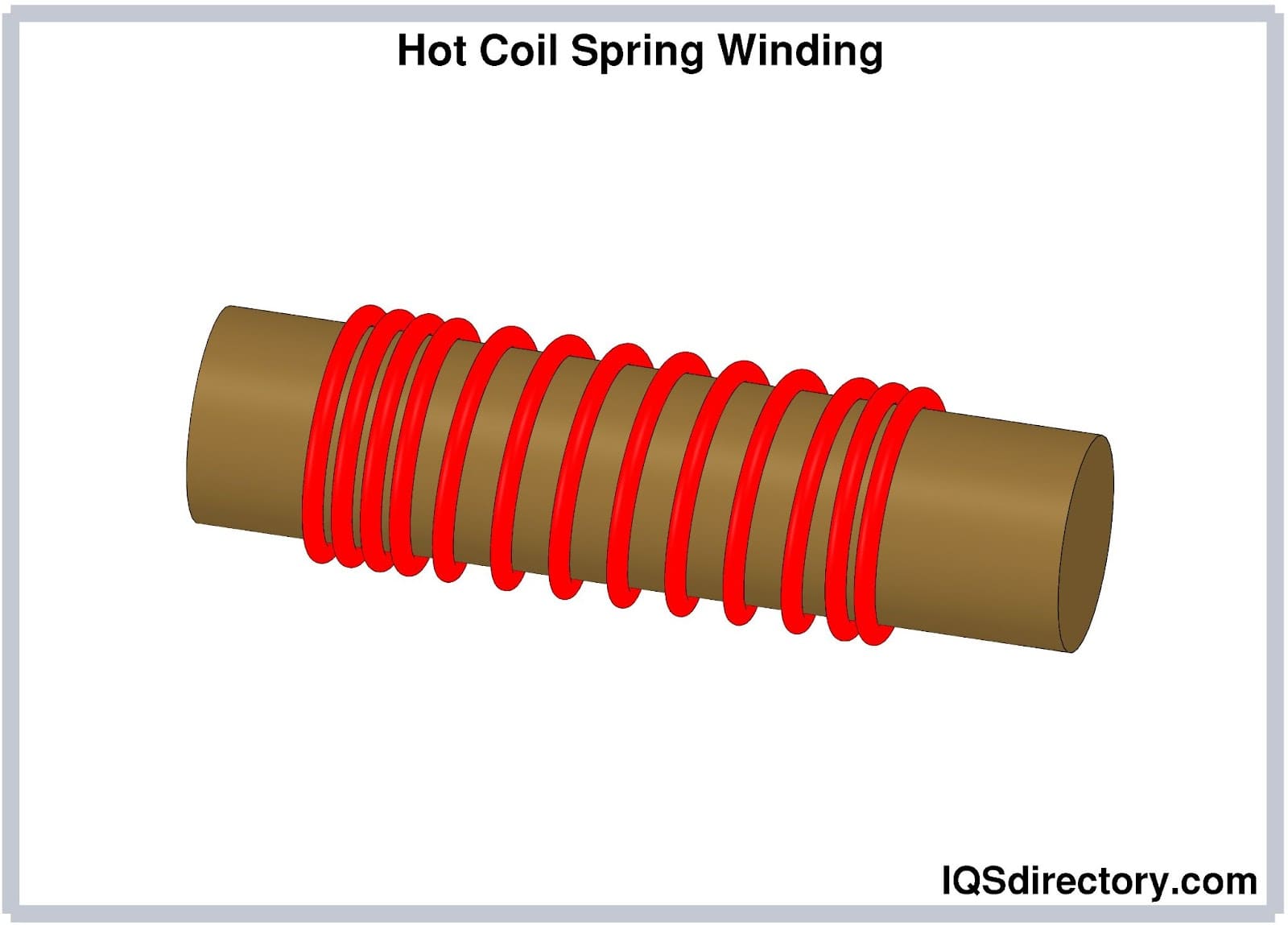

Metal coil springs are made by winding a wire around a shaped former – a cylinder is used to form cylindrical coil springs.

The design of double helical springs also offers some advantages in terms of space efficiency. Unlike single dislocation springs, which can be bulky, the double helical configuration can effectively compress into a smaller footprint. This compactness allows engineers to integrate these springs into applications where space is at a premium, without sacrificing performance.

It's also worth noting that the type and size of the wall brick tie can vary depending on the specific application. For example, ties used in residential construction may differ significantly from those employed in commercial buildings, where higher loads and different design considerations are at play. Additionally, architectural elements such as windows and doors may also influence the type of ties used.