1 4 wire mesh screen

Latest articles

1 4 wire mesh screen

...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More1. Choose according to the size of your dog

1 4 wire mesh screen...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More

1 4 wire mesh screen

Post time: 20-02-23...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More1 4 wire mesh screen

...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More1 4 wire mesh screen

...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More

1 4 wire mesh screenIron and steel in the condition of cooling on the surface galvanized, and hot dip galvanized steel pipe in the condition of hot dip on the surface, its adhesion is strong, not easy to fall off, hot dip galvanized pipe although also rust phenomenon, but in a long period can meet the technical and sanitary requirements.

...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More

1 4 wire mesh screen

Post time: 16-12-22...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read MoreZinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is to use the lead screw above the zinc pot, the length of the distance to the ceramic sinking roller. Thick wire diameter zinc dipping time should be long, fine wire diameter zinc dipping time should be short, zinc dipping length is in the range of 2~3.5m, which is also to reduce the zinc consumption of steel wire, is an aspect of maintaining the uniformity of zinc layer.

1 4 wire mesh screen...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More1 4 wire mesh screen

...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More1 4 wire mesh screen

...

1 4 wire mesh screen 【1 4 wire mesh screen】

Read More

Latest articles

-

② Electric galvanized shaft wire direct selling shall not be used for waist hoop compression reinforcement, usually not used for all binding.

-

-

Operating procedures: When using cold galvanized wire, all tools and stacked objects obstructing activities should be removed from the work site and equipment. When pickling, put the wire into the cylinder slowly to prevent acid splashing on the body. When adding acid, it is necessary to pour the acid into the water slowly. It is forbidden to pour the water into the acid to prevent the acid from splashing out. Wear protective glasses when working. Do not push or beat cold galvanized wire and other articles when handling them.

-

Post time: 30-05-23 -

Industrial rust prevention method: coated with asphalt, iron roof, coated with asphalt, you can prevent rust. Metal coating: Some metal surface will form a dense oxide film, can be coated on the surface of the metal composed of this metal screen. Such as: galvanized iron, tinplate plating, bicycle underwire and some medical equipment are coated with chromium and nickel.

-

Post time: 30-05-23

Links

The versatility of stainless steel boxes with locks is another compelling reason to consider them. They are not limited to a specific use; instead, they can serve various purposes across different contexts. In office environments, these boxes can securely store confidential files, protecting sensitive information from prying eyes. For individuals, they can serve as safes for important documents, jewelry, cash, or heirlooms. Additionally, in industrial settings, stainless steel boxes can safeguard tools and equipment, ensuring that everything is organized and protected against theft or damage.

- In conclusion, adjusting the wheels on a sliding screen door is a quick and easy way to resolve common issues and restore smooth operation. By following these simple steps, you can keep your door functioning properly and enjoy the convenience and beauty of this versatile feature for years to come.

Excellent weather resistance

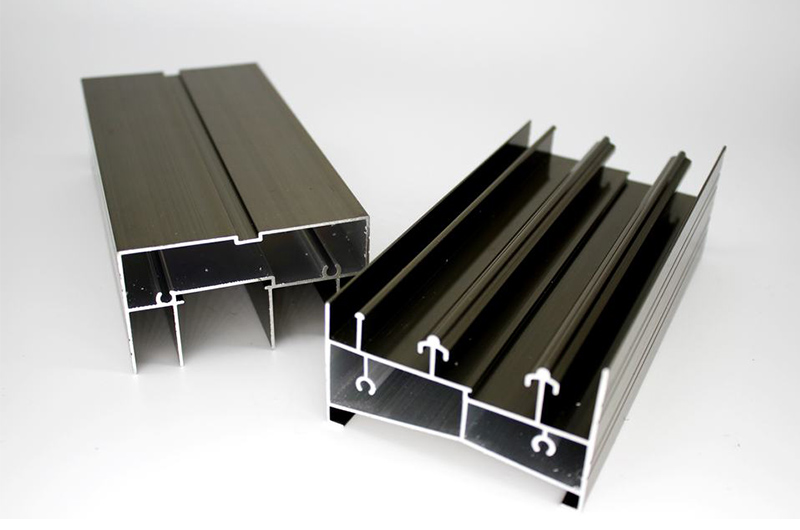

The aluminum alloy profiles are made of new thermal insulation materials. A cold and hot bridge is formed between the inner and outer profiles to minimize the thermal conductivity of aluminum alloy and achieve good thermal and sound insulation effects.

Stripping laces aluminum windows and doors profiles

Clean the window screens regularly: The window’s surface is susceptible to collecting dirt, dust, and grime, making it appear lifeless and gloomy. Use a gentle soap or glass cleaner, water solution, and a microfiber cleaning cloth to clean the door’s surface. Avoid using harsh chemicals or abrasive cleansers because doing so can ruin the door’s finish.

Locks and Latches: Mechanisms that secure the window closed or allow it to be opened to various positions.

Cast Iron Applications

Excellent for welded parts and assemblies

Rollers for aluminum sliding windows come in various designs, catering to the specific needs and preferences of users. Generally, there are two main types of rollers top-mounted and bottom-mounted.

1. Enhanced Energy Efficiency One of the primary advantages of thermal break aluminium profiles is their ability to improve a building's energy efficiency. Traditional aluminium frames conduct heat, resulting in significant energy loss. However, with thermal break technology, the flow of thermal energy is restricted, leading to a more stable indoor temperature.

Surface treatment: The aluminum profile is treated with a series of cleaning and pre-treatment processes to prepare it for painting. It is then powder-coated in a specialist powder coating booth and cured in specialist ovens .

The primary purpose of any box with a lock is to provide security. A stainless steel box equipped with a reliable locking mechanism offers peace of mind that your belongings are safe from unauthorized access. Whether you are storing sensitive documents, valuable tools, or personal items, the lock acts as a formidable barrier against theft or tampering. Many stainless steel boxes offer advanced locking systems, including combination locks, key locks, or even digital locks, ensuring that you can choose a security option that best fits your needs.

Most ornamental iron fences are machine made. They can be manufactured in large quantities and bought/sold in bulk.“Genuine” iron fences have not been commercially available since steel was popularized. However, you can still find the pieces needed to create a wrought iron fence, but rarely, if at all, will you find a true wrought iron fence manufacturer or mass producer.

This specific aluminum grade is highly machinable, weldable, and cold-worked. Additionally, you can use heat treatment, and it also offers suitable joining characteristics.

Beyond their functional attributes, stainless steel boxes with locks also boast a sleek, modern design that complements various settings. Their shiny finish and clean lines can add a touch of sophistication to any space, whether it’s an office, home, or workshop. Unlike bulky storage containers or unsightly filing cabinets, a stainless steel box can blend seamlessly into your décor, enhancing your space while serving a practical purpose.

Powder Coating

Powder coating is a safe, dry finishing process that uses finely ground particles of pigment and resin to create a protective finish. We choose to powder coat our steel frames because it is low in toxicity and has low flammability. The powder coating is then evenly melted and cooled into a thin, durable film. Powder coating can maintain its finish for up to 15-20 years, depending on pre-treatment and the type of powder. Its resistance to weather, corrosion, and chemicals makes powder coating a more durable finish than paint or other liquid coatings.