chain link extension

Latest articles

chain link extension

...

chain link extension 【chain link extension】

Read Morechain link extension

...

chain link extension 【chain link extension】

Read Morechain link extension

...

chain link extension 【chain link extension】

Read More2.25*2.25mm indicates that the two strands are 2.25mm silk, and the thorn thread is also 2.25mm silk;

chain link extension...

chain link extension 【chain link extension】

Read More

chain link extensionSince the reform and opening up, China has stopped a series of reforms and explorations on the grassland pasture use and animal husbandry operation system in grassland pastoral areas. In the 1980s, the grassland contract system was introduced in Inner Mongolia and other regions, under which grasslands were collectively used and farmers contracted to operate them separately. Stainless steel barbed wire fence is widely used by herdsmen in grassland pastoral areas

...

chain link extension 【chain link extension】

Read MoreCages are more often used to contain large dogs, which have a lot of strength. So the choice of dog cage must be strong, otherwise the dog is easy to break out of the dog cage.

chain link extension...

chain link extension 【chain link extension】

Read Morechain link extension

...

chain link extension 【chain link extension】

Read Morechain link extension

...

chain link extension 【chain link extension】

Read More

chain link extensionThe wire used for barbed wire is woven or welded with low carbon steel wire, medium carbon steel wire, high carbon steel wire, stainless steel wire and other materials. The production process includes: general braid, embossed braid and spot welding. If the material is steel wire, after equipment processing into a network, it is called wire mesh.

...

chain link extension 【chain link extension】

Read More

chain link extensionGalvanized iron wire is widely used in construction, handicrafts, wire mesh, highway guardrail, product packaging and daily civilian and other fields.

...

chain link extension 【chain link extension】

Read More

Popular articles

Many electrogalvanized wire diameter products are formed by wire drawing, wire drawing is a kind of processing technology, can make the product reach the required shape and meet the standard mechanical properties. Cold wire drawing is carried out at recrystallization temperature, hot wire drawing is carried out at crystallization temperature, warm wire drawing is drawn at higher than room temperature and lower than crystallization temperature. Cold drawing is a common drawing method.

Latest articles

-

But there are some necessary precautions in the production of galvanized wire. Remove all tools and piles on the work site and equipment that hinder activities, and slowly put the wire into the cylinder during pickling to prevent acid splashing on the body. When adding acid, the acid must be slowly poured into the water. Do not pour water into the acid to prevent acid spillage and injury. Workers should wear protective glasses when working. Then in the handling of wire and other items, it is strictly prohibited to push hard.

-

-

Post time: 14-02-23 -

The cage should be strong so that the bars cannot be bent or damaged by the parrot, and weak bars can be bent or damaged by the parrot and injure the parrot. Cages made of plastic coated railings can cause parrots to eat the coating and are not suitable. Quality cages are made of stainless steel, especially those made of colorful mild steel railings. Railing spacing is very important for the parrot’s safety, and the railing should always be small enough to prevent the parrot from poking its head out between the railing gaps. For small parrot species, column spacing of 1/2 inch (1.3 cm) is necessary. Medium parrot species such as grey parrots and Amazons require a 1 inch (2.5 cm) pitch, while great macaws can reach a pitch of more than 1 by inch (3.8 cm).

-

-

Stainless steel blade barbed wire production process is similar to galvanized blade barbed wire production process, usually according to the mold to determine the size of the blade.

Links

This flexibility is crucial in complex drilling operations where varying depths are required This flexibility is crucial in complex drilling operations where varying depths are required

This flexibility is crucial in complex drilling operations where varying depths are required This flexibility is crucial in complex drilling operations where varying depths are required drill extension rod.

drill extension rod. 5 AMP motor generates a forceful 4000 BPM, ideal for intense demolition projects5 AMP motor generates a forceful 4000 BPM, ideal for intense demolition projects

5 AMP motor generates a forceful 4000 BPM, ideal for intense demolition projects5 AMP motor generates a forceful 4000 BPM, ideal for intense demolition projects best pneumatic jack hammer. The ergonomic design, complete with a vibration-dampening handle, ensures user comfort even during marathon work sessions. The CP714 is also lightweight, enhancing maneuverability in tight spaces.

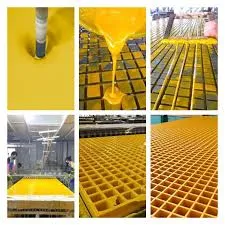

best pneumatic jack hammer. The ergonomic design, complete with a vibration-dampening handle, ensures user comfort even during marathon work sessions. The CP714 is also lightweight, enhancing maneuverability in tight spaces. frp customized product. Advanced techniques such as hand lay-up, spray lay-up, and vacuum infusion allow for intricate designs and shapes that would be impossible or impractical with other materials. This level of control ensures that every FRP product can be finely tuned to its intended application, maximizing efficiency and effectiveness.

frp customized product. Advanced techniques such as hand lay-up, spray lay-up, and vacuum infusion allow for intricate designs and shapes that would be impossible or impractical with other materials. This level of control ensures that every FRP product can be finely tuned to its intended application, maximizing efficiency and effectiveness.As we all know, there are fiberglass pultruded gratings and fiberglass molded gratings, but how to divide gratings by the shape? Generally speaking, fiberglass grating can be divided to four categories, the most important is divide according to product usage as well as the characteristics of their classification.

According to common usage rules it can be roughly divided to following few categories:

tungsten carbide button bits. During operation, these bits generate less heat than their softer counterparts, preventing workpiece damage and prolonging the bit's life. Coolant systems can also be integrated into the bit's design, further enhancing thermal management and lubrication during the cutting process.

tungsten carbide button bits. During operation, these bits generate less heat than their softer counterparts, preventing workpiece damage and prolonging the bit's life. Coolant systems can also be integrated into the bit's design, further enhancing thermal management and lubrication during the cutting process. When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

Molded fiberglass grating is available in various thicknesses, mesh patterns and dimensional sizes. Square mesh patterns enable the cutting of the panels efficiently, to accommodate a variety of floor layouts, while reducing the waste to minimal. Molded fiberglass mesh in rectangular shape is mostly used for trench covers in many industrial designs and is also a preferred grating option for walkways. The optional grit-top walking surfaces of fiberglass grating provide skid-resistance for the safety of the workers as well. The design of fiberglass grating is to ensure its reliability, in the most challenging conditions.

These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery

These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery fiberglass cover. Additionally, they provide an extra layer of safety by preventing accidental contact with moving parts or hot surfaces.

fiberglass cover. Additionally, they provide an extra layer of safety by preventing accidental contact with moving parts or hot surfaces. rock button bit. Construction companies use these specialized drill bits to create foundation holes, bore tunnels, and excavate rock for building projects. The rock button bit is essential for ensuring precise and efficient drilling, allowing construction projects to progress smoothly and on schedule.

rock button bit. Construction companies use these specialized drill bits to create foundation holes, bore tunnels, and excavate rock for building projects. The rock button bit is essential for ensuring precise and efficient drilling, allowing construction projects to progress smoothly and on schedule. rock button bit. Construction companies use these specialized drill bits to create foundation holes, bore tunnels, and excavate rock for building projects. The rock button bit is essential for ensuring precise and efficient drilling, allowing construction projects to progress smoothly and on schedule.

rock button bit. Construction companies use these specialized drill bits to create foundation holes, bore tunnels, and excavate rock for building projects. The rock button bit is essential for ensuring precise and efficient drilling, allowing construction projects to progress smoothly and on schedule. fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.

fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.