metal sheet with square holes

Latest articles

Purpose of galvanized hexagonal net: building wall fixed, heat preservation, heat insulation; Power plant tied pipe, boiler warm; Anti-freezing, residential protection, landscaping protection; Raising chickens and ducks, isolating chicken and duck houses, to protect poultry; To protect and support seawalls, hillsides, roads and Bridges and other waterworks.

metal sheet with square holes...

metal sheet with square holes 【metal sheet with square holes】

Read Moremetal sheet with square holes

...

metal sheet with square holes 【metal sheet with square holes】

Read Moremetal sheet with square holes

...

metal sheet with square holes 【metal sheet with square holes】

Read Moremetal sheet with square holes

...

metal sheet with square holes 【metal sheet with square holes】

Read Moremetal sheet with square holes

...

metal sheet with square holes 【metal sheet with square holes】

Read MoreLarge aperture hexagonal net is widely used in mountain, embankment protection, railway and highway isolation barrier, river channel management, soil consolidation berm, water conservancy engineering construction, rivers, DAMS and seawall anti-erosion protection and reservoir river interception, animal husbandry, grassland isolation guardrail, etc.

metal sheet with square holes...

metal sheet with square holes 【metal sheet with square holes】

Read Moremetal sheet with square holes

...

metal sheet with square holes 【metal sheet with square holes】

Read More

metal sheet with square holesGalvanized hexagonal mesh is a kind of galvanized metal wire mesh, the mesh shape is hexagonal.

...

metal sheet with square holes 【metal sheet with square holes】

Read More3, whether positive and negative twist, whether bilateral silk is needed.

metal sheet with square holes...

metal sheet with square holes 【metal sheet with square holes】

Read More

metal sheet with square holes

Post time: 29-08-22...

metal sheet with square holes 【metal sheet with square holes】

Read More

Popular articles

6, according to the wire diameter thickness to adjust zinc dipping time. Zinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is the length of the distance between the lead screw on the zinc pot and the ceramic sinking roll. The zinc dipping time of coarse wire diameter should be long, and the zinc dipping time of fine wire diameter should be short.

Post time: 24-04-22

Post time: 06-04-23- Hot dip galvanizing is in the hot melt zinc liquid dip plating, production speed, thick but uneven coating, the market allows the thickness of 45 microns, up to 300 microns above. It is dark in color, consumes more zinc metal, forms infiltration layer with base metal, and has good corrosion resistance. Hot dip galvanizing can be maintained for decades in outdoor environment. The protection of zinc coating on iron matrix has two principles: on the one hand, although zinc is more active and easy to oxidize than iron, but its oxide film is not as loose and compact as iron oxide. The dense oxide layer formed on the surface inhibits the further oxidation of zinc in the interior.

Latest articles

Links

- The sliding door roller system is primarily designed to provide smooth operation, ensuring that the door moves noiselessly and without any resistance. The rollers, usually made from high-quality materials like stainless steel or nylon, are attached to the top of the door and glide along the upper track. The lower track, or guide, keeps the door in alignment, preventing it from swaying or lifting off the track. This design not only enhances functionality but also contributes to the sleek, contemporary look of the interior.

- Maintenance of sliding door roller wheels is crucial for their longevity and optimal performance

What most people are after when they want a wrought iron fence is a certain appearance, like the distinctive look of wrought iron fencing in front of a Victorian house. To explain this look, you need to know something about ironwork. To start with, there are two main types of iron. Cast iron involves pouring the iron into a mold while it’s molten and allowing it to cool into a distinctive shape. Wrought (worked) iron is iron that has been heated until red hot, then pulled, twisted, or extruded into shape. These two processes used to be used to produce a variety of distinctive features in fences.

Energy-Efficient Buildings: Aluminium window profiles can be used with energy-efficient glazing to reduce heat loss and gain, contributing to lower energy consumption and a more sustainable building environment.

The Influence of Will on Wrought Iron Rust

Wrought Iron & Ornamental Iron

In addition to repairs, wrought iron welding near me can also be used for custom fabrication projects. This could include creating custom gates, fences, railings, or other decorative elements made from wrought iron. A reputable welding service will work closely with you to design and create the perfect piece to complement your home or business.

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box

What Is The Ideal Tolerance For Aluminum Profiles For Windows And Doors?

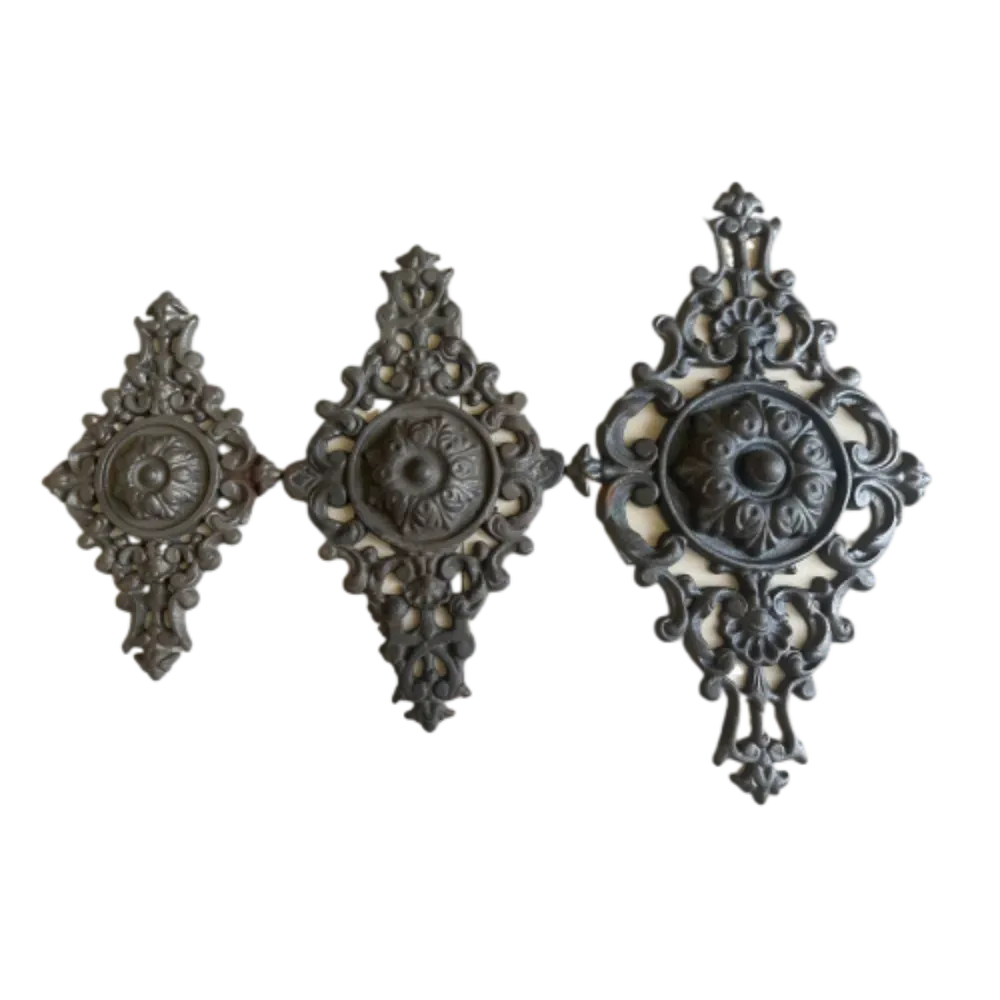

One of the most prominent uses of wrought iron is in the construction of gates, where ornaments play a crucial role in defining their visual appeal. Decorative elements such as scrolls, floral motifs, and geometric patterns can transform an ordinary gate into a stunning focal point. These adornments not only showcase the skill of the blacksmith but also reflect the personal style of the homeowner. Whether one prefers a traditional, ornate design or a minimalistic, modern look, there are wrought iron gate ornaments that cater to every taste.

At SHIJIAZHUANG TJJ TRADE CO.,LTD.(此处可链接至首页), we specialize in providing top-of-the-line door and window hardware solutions that combine unparalleled performance with exquisite design. Our extensive range of products caters to diverse needs, ensuring that every homeowner finds the perfect match for their style and requirements.

Commitment to Quality

Types of aluminum window profiles

Surface treatment: The aluminum profile is treated with a series of cleaning and pre-treatment processes to prepare it for painting. It is then powder-coated in a specialist powder coating booth and cured in specialist ovens .

cast iron designs.