expanded plate mesh

Latest articles

expanded plate meshBecause there are many large livestock in pasture, and because of the large cost of development and easy to be destroyed by livestock, galvanized barbed rope is the best choice for enclosure. Pasture installation thorn rope is necessary, wire mesh factory to introduce the role of pasture installation thorn rope。

...

expanded plate mesh 【expanded plate mesh】

Read MoreCommon weight length conversion of barbed rope:

expanded plate mesh...

expanded plate mesh 【expanded plate mesh】

Read More2. When there are natural barriers such as canals, ponds and lakes on the side of the road, barbed rope protection nets shall not be set up in the section where there is no need to worry about people and livestock entering and illegally occupying the road land.

expanded plate mesh...

expanded plate mesh 【expanded plate mesh】

Read More

expanded plate meshStainless steel barbed rope in the way of corrosion is not very, because the surface is not treated but rely on its own raw materials for corrosion resistance, so there will be no chemical reaction.

...

expanded plate mesh 【expanded plate mesh】

Read Moreexpanded plate mesh

...

expanded plate mesh 【expanded plate mesh】

Read Moreexpanded plate mesh

...

expanded plate mesh 【expanded plate mesh】

Read Moreexpanded plate mesh

...

expanded plate mesh 【expanded plate mesh】

Read Moreexpanded plate mesh

...

expanded plate mesh 【expanded plate mesh】

Read Moreexpanded plate mesh

...

expanded plate mesh 【expanded plate mesh】

Read MoreThe use of bundled galvanized wire with the development of industry and agriculture also expanded accordingly. Therefore, galvanized wire products in the industry, such as chemical equipment, oil processing, Marine exploration, transport, electricity, shipbuilding, metal structure, etc.), agriculture (such as sprinkler irrigation, dim room, building (such as water and gas transport, wire casing, scaffolding, house, etc.), Bridges, shipping, etc., has been widely use in recent years. Because galvanized wire goods have beautiful surface, good corrosion resistance and other characteristics, its use scale is more and more extensive.

expanded plate mesh...

expanded plate mesh 【expanded plate mesh】

Read More

Popular articles

- Hot dip galvanizing, also known as hot dip galvanizing, is a method of obtaining a metal covering by immersing a steel member in a molten zinc solution. With the rapid development of high-voltage transmission, transportation and communication, the protection requirements for steel parts are becoming higher and higher, and the demand for hot-dip galvanizing is also increasing. Usually the thickness of electric galvanized layer is 5 ~ 15μm, and the large roll galvanized wire layer is generally more than 35μm, even up to 200μm. Hot dip galvanizing has good covering ability, dense coating and no organic inclusions.

Annealing wire is widely used because it has a good elasticity and flexibility, in the annealing process can be good control of its hardness, it is mainly made of iron wire, more often used in the construction industry binding wire use. In the production of the wire factory, annealing wire will be processed according to the properties of the material, according to the needs of different to change its hardness degree, can make it has more advantages, can reduce the consumption of metal, reduce the cost of production.

Choose birds, raise birds before you need to choose the right birds, generally choose young birds, or minor birds, the requirements of health, strong activity, these birds are relatively easy to keep.

Post time: 21-07-22

Latest articles

-

Post time: 17-05-23 -

-

-

The temperature of large roll galvanized wire should be controlled at 30 to 50℃ during electroplating. Because the chloride ions in the bath are very corrosive, quartz glass heaters are generally used. Continuous production does not need heating, but needs cooling. Cooling can be in the groove side row thin wall plastic pipe, through the flow of tap water cooling, can also be used as a titanium pipe temperature control device.

-

There are various specifications of barbed rope, which can be divided into two categories: ordinary barbed rope and blade barbed rope.

-

Links

Current PP bag stitching machines come with various features designed to improve performance and user experience. These machines typically incorporate automated feeding systems that ensure a consistent flow of bags, reducing downtime and labor costs. Additionally, many models have adjustable stitch patterns, allowing manufacturers to modify the closing technique depending on the bag's intended use.

An automatic button sewing machine is a specialized device that automates the process of sewing buttons onto fabric. Unlike manual machines, which require the user to position the fabric and button carefully, these automatic machines take over most of the heavy lifting. They use pre-set patterns and allow users to select the button size and type, ensuring consistent and precise results. This innovation drastically reduces the time needed for this common sewing task, freeing up hours for creativity and production.

- Another important factor to consider when choosing needles for sewing leather is the type of stitching you will be doing. If you are sewing seams or topstitching leather, you will need needles with a cutting point or wedge point, as these needles are designed to cut through the leather as they sew. For decorative stitching or embroidery, you may want to use needles with a rounded or ball point, which will glide through the fabric without causing damage.

Before diving into the sewing process, it's essential to understand the different types of leather. Full-grain leather is the most durable and retains the natural texture of the hide. Top-grain leather is slightly more processed and has a smoother finish. Suede is made from the underside of the hide and has a soft texture, while bonded leather combines leather scraps with synthetic materials. Each type has its own sewing requirements, so it's crucial to choose the right leather for your project.

When working with thick materials, it’s essential to have control over the presser foot pressure. An adjustable presser foot allows you to customize the amount of pressure applied to the fabric, which is vital for achieving even stitches and preventing puckering or dragging. Make sure the sewing machine you choose has this feature.

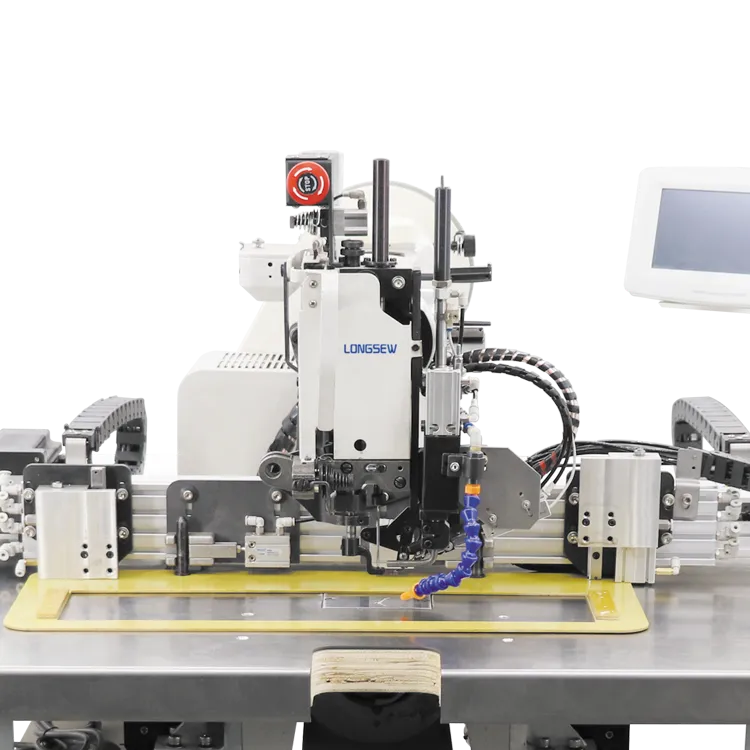

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

Understanding Single Needle Top Stitching

Maintenance of Heavy Duty Sewing Machine Motors

3. Cost-Effectiveness Investing in gunny bag sewing machines can yield substantial cost savings in the long run. The durability of the stitched bags reduces losses due to spillage or contamination, while the speed of operation allows businesses to scale up production without a significant increase in labor costs.

All walking foot sewing machines come with a cast iron finish and all metal working parts. Metal gears and parts will last much longer than any sewing machine with plastic gears and parts. Plastic gears and parts crack and break down quickly. Having a cast iron body proves to be much more durable than plastic bodies. If the machine drops, it will not shatter into 100 pieces. Durability is much higher with a walking foot sewing machine.

Challenges and Considerations

5. Extended Workspace Professional upholstery sewing machines often feature a larger table area. This additional space is invaluable when handling large upholstery projects, making it easier to maneuver fabrics without constraint.

This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear

This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear This versatility allows dressmakers to create a wide range of garments, from elegant evening gowns to casual everyday wear dressmaker deluxe zig zag.

dressmaker deluxe zig zag.Advantages of Using a Double Needle Sewing Machine

The applications of double needle lockstitch machines span a wide range of industries. In the apparel sector, they are used for sewing sportswear, children's clothing, and other garments that require durability and flexibility. The machine's ability to handle multiple layers of fabric makes it perfect for producing items like jackets or quilts, where strength is paramount.

1. Improved Stitch Quality Using a zigzag presser foot ensures that the zigzag stitches are uniform and even, preventing issues such as skipped stitches or uneven tension.

One of the significant advantages of machine embroidery in quilting is the ability to customize designs. Many quilting machines come with built-in editing software, allowing users to resize, rotate, and combine different elements to create a unique pattern. This feature empowers quilters to personalize their projects, adding their touch and making each quilt a true reflection of their style.

Conclusion

3. Control Panel The control panel is the operator’s interface with the bag closer machine. It allows for the adjustment of settings such as sealing temperature, speed, and pressure. Modern machines may also include digital displays and programmable features, enhancing user control and monitoring capabilities.

This combination of upper and lower threads creates a locked stitch, hence the name. The stitch type is denoted by the establishment of a series of continuous, parallel lines on the fabric's surface. The simplicity of the single needle lock stitch makes it a favorite among sewers; it can be easily manipulated for various fabric types and thicknesses.

The Versatility of Coverstitch Chain Stitch in Garment Construction

Exploring Handheld Sewing Machines

Finally, if you experience issues with the motor or other mechanical components of the machine, it’s best to consult with a professional technician or contact the manufacturer for assistance. Attempting to repair complex mechanical issues without proper knowledge or training can lead to further damage to the machine.

Canvas Products

The Evolution and Impact of Automatic Computerized Sewing Machines

- Practice Makes Perfect If you are new to leather stitching, take some time to practice on scraps before moving onto your main project. Familiarizing yourself with the tool's operation will enhance your confidence and skill.

The Role of Automatic Bag Closer Machines in Modern Packaging

Difference Between Heavy-Duty And Industrial Sewing Machines

Investing in a heavy-duty home sewing machine is not just about its immediate capabilities; it's also about the longevity it offers. These machines are engineered to last, making them a worthwhile investment for anyone serious about sewing. They require less frequent repairs and maintenance compared to lighter models, allowing you more time to focus on your projects rather than fixing your machine.

2. Aesthetic Appeal The parallel lines of stitching not only enhance the durability of leather products but also add a visually appealing element. This characteristic is particularly important for items such as bags and garments, where aesthetics play a crucial role in consumer choice.

- Keychains Small and manageable, perfect for learning basic stitches.

Final Thoughts

4. Adjustable Stitch Length Having the option to adjust stitch length is important when working on projects involving fur and leather. Thicker materials typically require longer stitch lengths to avoid perforating the leather and damaging the fur. A sewing machine that allows for easy adjustments will give you greater control over your projects.

The Evolution and Impact of CNC Programmable Sewing Machines in Modern Textile Manufacturing

What is a Serger Machine?

Hand-powered leather sewing machines are favored in several leatherworking applications. From creating bespoke leather bags and wallets to crafting intricate leather belts and saddles, these machines can handle a wide range of projects. Artisans who specialize in custom leather goods often prefer these tools, as they allow for full customization in terms of design, stitch type, and tension settings.

Enhancing Efficiency and Productivity

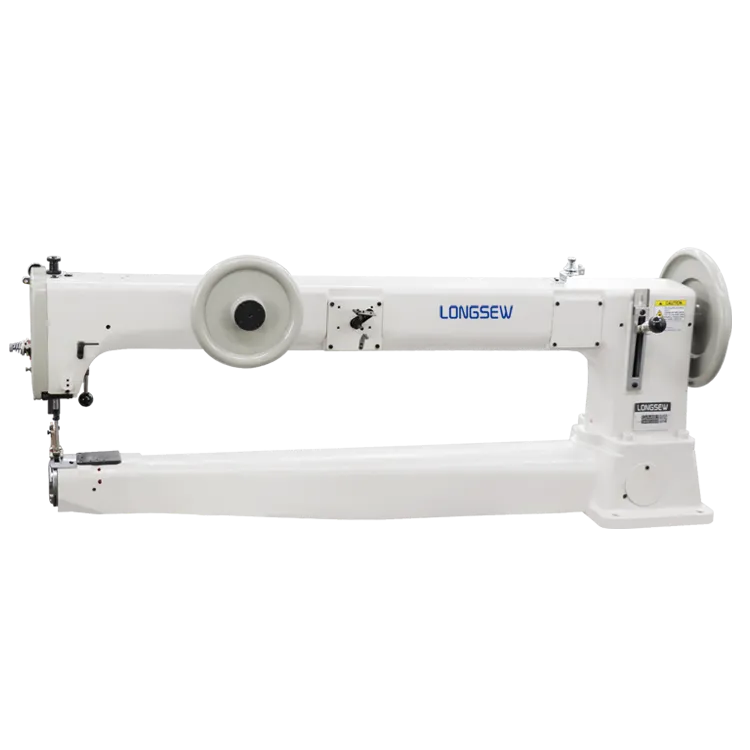

long arm sail sewing machine with puller

4. Quality of Stitches The even feeding mechanism results in straighter, more evenly spaced stitches, which enhances the overall quality of your finished project. This is particularly important for intricate designs and quilts.

walking foot sewing machine for sale

What Makes Heavy Duty Sewing Machines Different?

As technology continues to advance, the future of high-speed overlock sewing machines appears promising. Innovations such as computerized controls, integrated cutting systems, and enhanced automation are expected to further streamline the sewing process. The integration of sustainability practices, such as fabric-saving features and energy-efficient operations, will also likely gain traction as the industry shifts towards more environmentally friendly practices.