3d eps wire mesh panel

Latest articles

3d eps wire mesh panelDog cage mainly by welding, spraying, injection molding, surface treatment, electroplating dog cage is made of high quality steel wire, dog cages are with plastic and plastic surface treatment, electrophoresis, chrome plating, galvanized, imitation gold, etc., according to the customer request processing, respectively, also can be customized to sample, dog cage assembly of compact structure, neat and beautiful appearance, make folding and remove the cage is more convenient and quick, won’t take up too much space.

...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More

3d eps wire mesh panelGuardrail in the purchase of how to install the correct is very important, and the installation of guardrail is important, the requirements of height and material are very strict.

...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read MoreIf the surface of galvanized wire is black and the galvanized layer is thin and uneven, the galvanized wire is partly because the inventory storage time is longer, but also because the production technical requirements of galvanized wire do not meet the standard and lead to the quality problems of galvanized wire. According to the use of galvanized wire is different, galvanized wire has soft and hard, then the galvanized wire used for binding requires the flexibility of galvanized wire is better, the flexibility of galvanized wire is good, and it can be easy for workers to operate.

3d eps wire mesh panel...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More

3d eps wire mesh panel

Post time: 08-05-23...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More

3d eps wire mesh panelBlade barbed rope production links need to be many times before the finished product, roughly down to four or five links.

...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More3d eps wire mesh panel

...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read MoreHexagonal mesh is metal wire woven Angle mesh (hexagonal) made of barbed wire, the use of wire diameter is different according to the size of the hexagonal.

3d eps wire mesh panel...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read MoreGalvanized iron wire has excellent endurance and elasticity, zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, wire mesh, highway guardrail, commodity packaging and ordinary civilian and other categories.

3d eps wire mesh panel...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More3d eps wire mesh panel

...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More3d eps wire mesh panel

...

3d eps wire mesh panel 【3d eps wire mesh panel】

Read More

Popular articles

- 3. Daily maintenance of the blade stabbing rope

- Excellent anticorrosive makes its popularity in the feed, the net surface smooth and tidy, increased the look and feel, can be adornment effect, this characteristic makes it to show in the mining industry, due to high quality with low carbon materials as raw materials, to make it unique general iron mesh screen does not have flexibility, determine its plasticity in use process, It can be used for the deep processing manufacturing of hardware technology, the batch swing of complex wall body, underground leakage prevention and cracking prevention, light net body, so that this cost is much lower than the cost of iron screen, more can realize its economy and benefit.

- Of course, the quality of any kind of product is also affected by the implementation of the specification of the manufacturer, if it is the welding screen manufacturers in the production of their own is not very high implementation of the specification, or in the production line of the procedure specification has declined, or there is no higher requirements on the production link.

Post time: 12-04-23

Latest articles

-

The effect of chemical composition and metallographic structure of steel wire

-

-

High quality galvanized wire in general, the zinc layer attached to the surface of the wire is relatively thick, so when we buy galvanized wire, as long as we look at the thickness of the zinc layer machine, we can generally judge whether the quality of galvanized wire is high quality.

-

-

-

During this process, each time the wire is pulled over, the surface hardens due to the high friction temperature. So basically every time you pull it you have to annealing it in the furnace. On the one hand, it is to reduce the surface hardness. On the other hand, during the process of wire pulling, only the surface is deformed, and the center is unchanged. So there’s a lot of stress inside. Therefore, it is necessary to rely on annealing to eliminate the internal stress, so that the wire becomes soft again to eliminate the stress before being drawn again.

Understanding Thick Threads

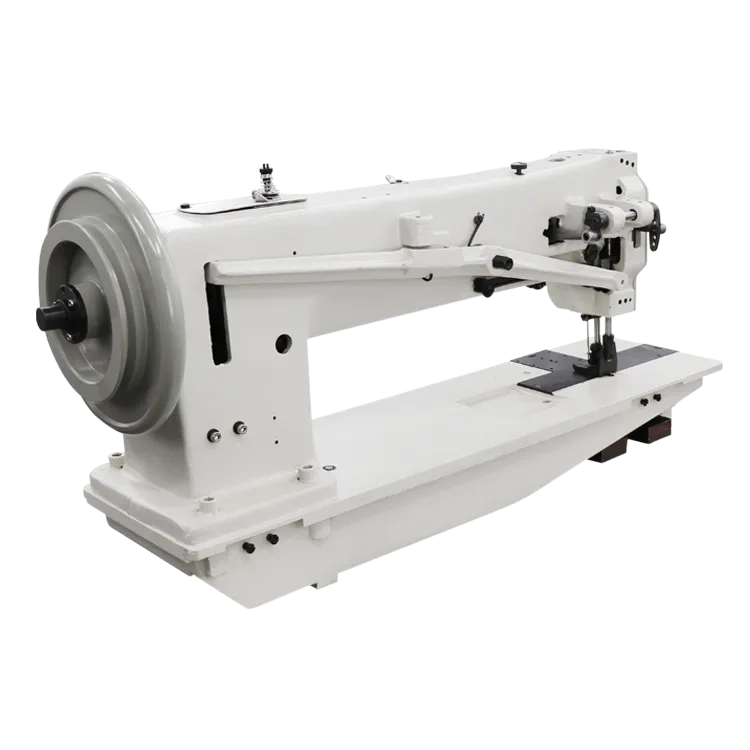

The manual lockstitch sewing machine operates using a simple yet effective mechanism. The user controls the machine with a foot pedal, which allows for speed regulation and precise stitching. The needle moves up and down, piercing the fabric and drawing the top thread through, while the bobbin supplies the lower thread from beneath. This interlocking of threads creates the iconic lockstitch that is favored for its strength and versatility.

Understanding the Industrial Chain Stitch Machine A Key Player in Textile Manufacturing

3. High-Speed Stitching Machines Designed for large-scale production, high-speed machines can significantly increase output while maintaining quality, making them a popular choice for manufacturers looking to scale operations.

Leather hand stitching is an ancient craft that marries functionality with artistry, creating unique and durable items that stand the test of time. From wallets and belts to bags and shoes, hand-stitched leather goods are celebrated for their beauty and craftsmanship, offering a personal touch that machine-made products often lack.

The Price of Double Needle Sewing Machines An Overview

If you are a beginner or hobbyist, you may not need all the bells and whistles that come with a more expensive machine. In this case, you could opt for a more budget-friendly option that still offers a reliable performance for your sewing projects. On the other hand, if you are a professional seamstress or tailor, investing in a higher-end model with advanced features may be worth the extra cost.

Benefits of CNC Machine Sewing

What are FIBC Spout Rosettes?

sewing cnc machine.

automatic bag closer sewing machine. Most models feature user-friendly controls and settings, allowing operators to quickly set up the machine for different bag sizes and materials. This versatility and ease of use make the machine suitable for businesses of all sizes, from small-scale operations to large industrial facilities.

Modern domestic lockstitch sewing machines come equipped with a variety of features that enhance their usability and efficiency. Most machines offer adjustable stitch lengths and widths, allowing users to customize their sewing experience according to the project at hand. Additionally, many machines include built-in stitches, such as zigzag and decorative stitches, providing even more creative possibilities.

Modern CNC sewing machines are equipped with advanced computer systems that allow for intricate designs and patterns to be programmed directly into the machine. This has enabled manufacturers to produce complex garments and textiles with relative ease. For instance, a designer can create a unique embroidery pattern on a garment by simply inputting the design into the CNC software, which then guides the machine to stitch it out accurately.

1. Increased Efficiency The capability to create two lines of stitching in one pass significantly boosts production speed. This efficiency is especially beneficial in high-volume manufacturing environments, where time is a critical factor.

double stitch machine

Understanding the Prices of Saddle Stitch Machines

When it comes to sewing, the choice of thread plays a pivotal role in the overall durability and quality of the finished product. One type of thread that stands out for its robustness and reliability is heavy-duty denim thread. As the name suggests, this thread is specifically designed for sewing denim fabric, which is known for its thickness and strength. In this article, we will explore the characteristics, benefits, and applications of heavy-duty denim thread, making it an indispensable tool for anyone working with tough materials.

Investing in a heavy-duty home sewing machine is not just about its immediate capabilities; it's also about the longevity it offers. These machines are engineered to last, making them a worthwhile investment for anyone serious about sewing. They require less frequent repairs and maintenance compared to lighter models, allowing you more time to focus on your projects rather than fixing your machine.

Different stitches serve various purposes, especially when dealing with thick fabrics. A good sewing machine should have a variety of stitch options, including straight stitches, zigzag stitches, and even decorative stitches. Additionally, being able to adjust stitch length is essential when sewing thick materials. Longer stitch lengths are usually preferred for heavy fabrics to allow for better flexibility and easier movement.

Advantages in Industrial Settings

domestic special sewing machine. With features like drop feed and free-motion quilting, domestic special sewing machines offer the flexibility and control you need to tackle a wide range of sewing tasks.

In the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the essential tools in this domain is the bag closer machine, a device designed to seal bags containing a variety of products, from food items to industrial materials. To ensure optimal performance, understanding the various parts of a bag closer machine is crucial.

What is Automatic Backstitch?

Getting Started with Multi-Needle Quilting

One of the key advantages of the single needle stitch is its versatility. It is commonly employed in various applications, from delicate hems on silk dresses to intricate embellishments on leather goods. Designers often opt for this stitch when they aim to achieve a clean and minimalist aesthetic. Moreover, the single needle stitch is ideal for working with lightweight and sheer fabrics, where bulkiness might ruin the overall look.

A PP bag silai machine is specifically designed for sewing and stitching polypropylene bags, which are commonly used for packaging agricultural products, industrial materials, and consumer goods. These machines are engineered to handle various bag designs and sizes, making them an essential tool in factories that manufacture PP bags.

This was precisely the machine for me. My aim, beyond some light garment tailoring, is to add upholstery to my quiver of skills, thereby making my pipe dream of amateur furniture making closer at hand. My friend Eric had extolled the virtues of his own adventures in sewing and by this point in the pandemic I’d just about run out of Netflix to watch. So: Sewing, it is!

- Sportswear The need for durability and stretch in sportswear makes this machine ideal for stitching seams that require high performance.

Another factor to consider in pricing is the timing of your purchase. Sewing machines are often discounted during promotional events such as Black Friday, Cyber Monday, or spring sales. Retailers may also offer discounts on previous year’s models to make way for newer inventory. Shoppers looking for a bargain can significantly benefit from keeping an eye on seasonal sales and clearance events, allowing them to purchase a higher-quality machine for a lower price.

Furthermore, an automatic needle threader can enhance the versatility of sewing machines

. Many modern machines equipped with this technology also come with advanced features such as multiple stitch options, embroidery capabilities, and adjustable speed controls. This combination allows for a more comprehensive sewing experience, where users can explore various projects, from simple repairs to intricate designs, all while benefiting from the ease of automatic threading.1. Speed and Efficiency Overlockers can sew, cut, and finish fabric edges in one go. This reduces the time spent on each piece, allowing manufacturers to increase production capacity and meet deadlines more effectively.

B. Benefits of Heavy Duty Machines:

In this section, we’ll delve into the advantages of using heavy duty sewing machines. We’ll highlight their durability, reliability, and ability to sew through multiple layers of fabric. Additionally, we’ll discuss how heavy duty machines can save time and effort by offering faster stitching speeds.

Industrial Overlockers for Sale A Comprehensive Guide

Why Choose Heavy-Duty for Vinyl?