grow box plant support cage

Latest articles

grow box plant support cageSpeaking of pets, we have to talk about parrots. Because it’s easy to take care of, and it can talk, talk to you, and make you laugh. Parrots love to climb, so there is a cage with bars that are made up of horizontal bars rather than vertical bars, because this makes climbing easier for the parrots.

...

grow box plant support cage 【grow box plant support cage】

Read More

grow box plant support cageThe different spacing of the thorn rope is mainly in order to save costs to consider, because if they are too close, then obviously a little waste of resources, but the installation is too sparse will not work. Usually the bottom spacing is about 10cm, and the top is up to 20cm, this is because the higher the place is more difficult to climb over, usually more than one meter without the help of tools it is difficult for ordinary people to climb over, and the bottom because of the relatively tight can prevent personnel from drilling in the past.

...

grow box plant support cage 【grow box plant support cage】

Read More

grow box plant support cageWith the improvement of people’s living standards, kittens, dogs and other small pets also need a stable nest, pet cage has become a more important choice for people to raise pets. Suitable cat cage, dog cage is very necessary for kittens and dogs. There are many kinds of pet cage, cat cage, dog cage selectivity is relatively large, pet cage is generally made of thicker wire, and then get a base with wheels at the bottom, such a simple pet cage is made.

...

grow box plant support cage 【grow box plant support cage】

Read Moregrow box plant support cage

...

grow box plant support cage 【grow box plant support cage】

Read More

grow box plant support cageCompared with traditional braided and twisted braided rope, the process of blade braided rope is relatively complex, and the price of raw materials is also relatively high.

...

grow box plant support cage 【grow box plant support cage】

Read MoreIn use, it can be well used to control its soft and hard degree in the annealing process, mainly used in the construction industry as a binding wire and binding line. Of course, its use is not limited to arts and crafts, but also widely used in the construction industry. Earlier woven lanterns were made of iron wire with appropriate candles placed inside. People hung them in front of their doors and looked very beautiful at night.

grow box plant support cage...

grow box plant support cage 【grow box plant support cage】

Read More

grow box plant support cageSteel wire after galvanized treatment, the surface will be covered with a layer of zinc metal, to play the role of anti-corrosion, anti-fouling, enhance strength and beauty. The galvanized wire drawing treatment is to process the steel wire by stretching method to obtain a finer, higher strength and smoother surface, and improve its mechanical properties. However, will wire drawing affect the electrical conductivity of galvanized steel wire?

...

grow box plant support cage 【grow box plant support cage】

Read More③ Galvanized iron wire shall not be damaged when it is tightened.

grow box plant support cage...

grow box plant support cage 【grow box plant support cage】

Read Moregrow box plant support cage

...

grow box plant support cage 【grow box plant support cage】

Read Moregrow box plant support cage

...

grow box plant support cage 【grow box plant support cage】

Read More

Popular articles

Galvanized hook net cost is low: galvanized process is faster than other coating construction method, and can avoid the installation of time required on the site brushing; Galvanized hook net features: not easy to corrosion, long life, strong practicality, uniform mesh, smooth net surface, simple weaving, beautiful and generous, high quality mesh, wide mesh, thick wire diameter. Can do breeding protection net, coal mine protection net, court protection net, stadium fence net, training field protection net, slope protection, green enclosure, river, building, residential district safety protection, workshop/warehouse isolation, etc..

Now when most people buy barbed rope, they choose blade barbed rope. Why is this? From the material, the blade barbed wire process is made of hot-dip galvanized steel plate or stainless steel sheet to press the sharp blade sheet, and the high-tension galvanized steel wire or the blade barbed wire is made of stainless steel wire as the core wire. Because the shape of the gill net is not easy to contact, so it can reach an excellent protective barrier effect.

The quality of hot-dip galvanized barbed wire is only in the surface of the wire attached to the galvanized layer, and with the reason of the chemical reaction, the surface of the zinc layer will gradually lose its role because of the oxidation reaction, this situation is more prominent in humid areas. And because after all, the steel wire will rust, so the quality of hot-dip galvanized barbed wire is certainly not up to the level of stainless steel barbed wire.

Large aperture hexagonal mesh is also called large size hexagonal mesh, large wire hexagonal mesh, heavy hexagonal mesh, heavy stone cage mesh, gabion mesh, large wire mesh, is the use of 1.8mm-4.0mm metal wire diameter by mechanical woven into the twisted hexagonal wire mesh products.

- 5, there are no special requirements: such as whether to shrink packaging, etc.

Latest articles

-

Post time: 28-04-22 -

The production process of stainless steel blade and galvanized blade is basically similar. The blade size is usually determined according to the mold.

-

Weaving and features: mesh uniform, flat, woven, crocheted, beautiful and generous; Good mesh, wide mesh, coarse diameter, not easy to corrosion, long life, strong usefulness. Usefulness: widely used in highway, railway, highway and other guardrail equipment. To choose the hook mesh permeability special effect, a large area of application in mountain protection, used to fix the rock, together with the selection of green grass spray to reach the late curing effect. It is a perfect separation of greening and protection.

-

-

Post time: 07-07-22 -

Links

- Introduction

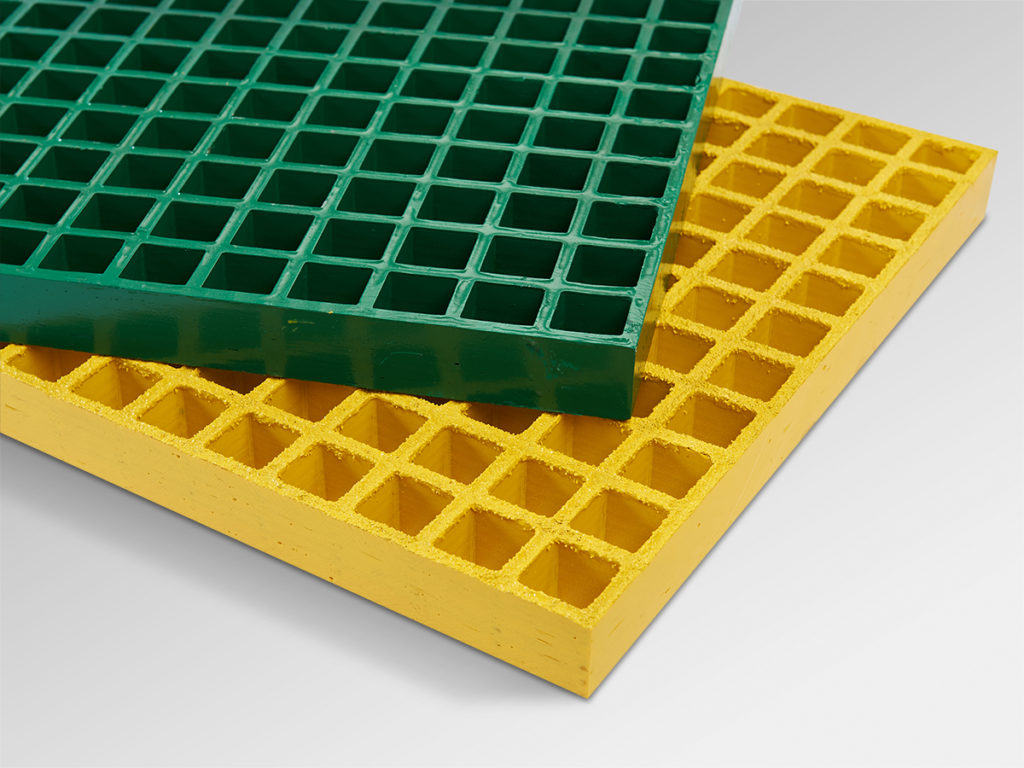

- The primary advantage of plastic gratings lies in their resistance to corrosion. Unlike traditional metal gratings, which can rust or corrode over time, especially in harsh or wet conditions, plastic gratings maintain their integrity and strength even when exposed to chemicals, saltwater, or extreme weather. This makes them perfect for use in industrial settings such as chemical plants, oil refineries, and wastewater treatment facilities, as well as coastal areas and bridges where exposure to corrosive elements is high.

- The Versatility of Cutting Drill Bits

- oil & gas

- The button element highlights the innovative design of these bits

- Exploring the Market for Rock Drills Features and Considerations for Prospective Buyers

- Firstly, the size alone denotes its purpose. A 42mm drill bit is a behemoth in comparison to standard bits, which typically range from 1mm to 13mm. Such a large diameter allows it to handle massive holes in materials like wood, concrete, and even metals, making it an indispensable tool for large-scale construction or renovation projects.

- Moreover, mine extension drill rods with improved thread designs and coatings have enhanced the drilling process

- 18. Oil-hardened hammer drill bits Heat-treated for added strength, they offer reliable performance in various drilling tasks.

- The 90% Pneumatic Jackhammer A Revolution in Construction Efficiency

fiberglass chemical tank. Their smooth, glossy surface is easy to clean and maintain, ensuring that they remain looking good even after years of use. And because they are available in a range of colors, they can be matched to existing equipment or branding schemes for a cohesive look.

fiberglass chemical tank. Their smooth, glossy surface is easy to clean and maintain, ensuring that they remain looking good even after years of use. And because they are available in a range of colors, they can be matched to existing equipment or branding schemes for a cohesive look.Gratings & Covers

Specialty Steel supplies various types of clips for its gratings. We offer specially designed attachments and clips that both fasten panels together and secure them to support structures. All clips are made of type 316 Stainless Steel and are available in 1”, 1-1/2” and 2” sizes. Call us today to find the perfect clip for your molded grating project.

portable jack hammer for sale. They are designed to be durable and long-lasting, so you can rely on them to get the job done time and time again.