thin wire trellis

Latest articles

thin wire trellis

...

thin wire trellis 【thin wire trellis】

Read More

thin wire trellisGenerally speaking, in dry main gas and indoor use, the thickness of galvanized coating is only 6-12μm, but under poor environmental conditions, the thickness of galvanized coating is 20μm, can reach 50μm. Therefore, environmental factors should be considered when choosing the thickness of galvanized layer. Galvanized layer after passivation treatment, can naturally form a layer of bright, beautiful color passivation film, can obviously improve its protective function, decorative.

...

thin wire trellis 【thin wire trellis】

Read Morethin wire trellis

...

thin wire trellis 【thin wire trellis】

Read More

thin wire trellisAfter proper heat treatment or cold drawing hardening, high carbon steel wire has high strength and hardness, high elastic limit and fatigue limit (especially notched fatigue limit), cutting function is acceptable, but welding function and cold plastic deformation ability is poor.

...

thin wire trellis 【thin wire trellis】

Read More1, galvanized wire mesh molding sheet must be packed with flat hard data, to avoid eternal deformation due to poor packaging. It IS VERY IMPORTANT THAT EACH PACKAGE AND ROLL OF RAW SHEET MATERIAL BE MARKED WITH PRODUCT NAME, STANDARD, QUANTITY, TRADEMARK, batch number, MANUFACTURER, DATE of production, STACKING SYMBOL, INSPECTOR CODE AND INSPECTION CERTIFICATE.

thin wire trellis...

thin wire trellis 【thin wire trellis】

Read MoreCore diameter: according to customer requirements (mm)

thin wire trellis...

thin wire trellis 【thin wire trellis】

Read Morethin wire trellis

...

thin wire trellis 【thin wire trellis】

Read MoreThird, 201 is high manganese content, the surface is very bright with dark bright, high manganese content is easy to rust. 304 contains more chromium, the surface is matte, no rust. Put the two together and you have a comparison. The most important thing is that the corrosion resistance is different. The corrosion resistance of 201 is very poor, so the price will be much cheaper. Because of the low nickel content of 201, the price is lower than 304, so the corrosion resistance is not as good as 304.

thin wire trellis...

thin wire trellis 【thin wire trellis】

Read Morethin wire trellis

...

thin wire trellis 【thin wire trellis】

Read More

thin wire trellisWet air in rain and snow climate, steel mesh sheet exposed, easy to rust, to avoid affecting the use of steel mesh, it is necessary to carry out simple rust prevention treatment, of course, slight rust float will not affect the use of steel mesh. Common network site storage, rainy days, heavy snow, rainy days and rainy days, how to better save the steel mesh, this is a lot of friends need to consider.

...

thin wire trellis 【thin wire trellis】

Read More

Popular articles

Post time: 22-09-22Hot-dip galvanized wire has longer service life and better corrosion resistance than ordinary steel wire. Hot dip galvanizing is a method of chemical combination of zinc metal and steel wire surface, through the formation of a strong and self-healing zinc-iron alloy protective layer on the steel wire surface, so as to prevent direct contact between the steel wire and the external environment, reduce the possibility of oxidation corrosion, and extend the service life of the steel wire.

The shape of the cage has round, square, octagonal, hexagonal and other shapes. Because the circular space uses a large area, it is more suitable for the activities of birds, and it is not easy to get hurt, so it is popular with everyone. A cage is dear to a man who loves birds, for it is inhabited by his master’s birds. If well maintained, it can be maintained for many years. Let’s look at how to maintain the cage.

Latest articles

-

Sodium and magnesium contain less combustible impurities, and when extinguished, they simply glow. Galvanizing belongs to the electrochemical processing process which is widely used on the surface of steel. So it is, first of all, because zinc coating (especially after supplementary processing, such as chromate treatment and phosphating) resistance to atmosphere and water is more stable, and the galvanized process itself this is cheaper and simple.

-

-

Production technology: Through the excellent low carbon steel rod drawing forming, pickling rust removal, high temperature annealing, hot dip galvanizing. Cooling and other 5 operation processes refined. Galvanized wire characteristics: good resistance and elasticity, strong corrosion resistance.

-

Post time: 17-02-23 -

-

Links

(1) Special personnel must be responsible for large lifting tools, use them appropriately, and strictly observe.Lifting rules to prevent vibration, impact, deformation or damage during the lifting process.

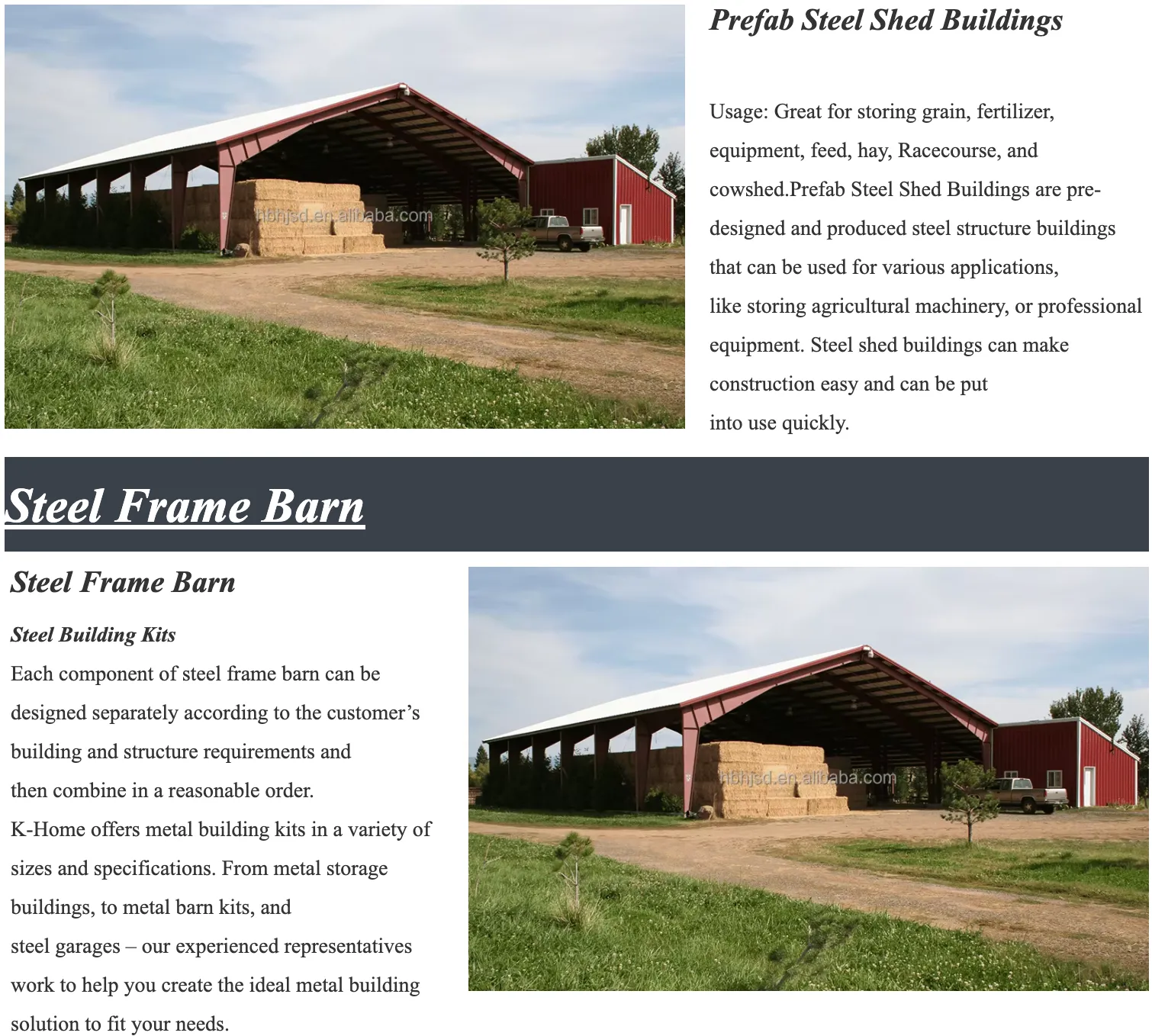

Additionally, metal structures are fire-resistant, which enhances the safety of the workplace. In environments where flammable materials are stored or handled, the fire-resistant properties of metal buildings can provide peace of mind to business owners and employees alike. Furthermore, metal construction is typically quicker and more efficient than traditional construction methods, allowing businesses to move into their new facilities sooner and start generating revenue.

Moreover, the introduction of smart technologies is transforming how industrial sheds are monitored and maintained. Sensors can be integrated into the frame to track structural integrity, monitor temperature, and even control ventilation systems, enhancing operational efficiency and safety.

The Rise of Metal Garage Shops A New Era in DIY Projects

The Rise of Metal Building Home Manufacturers

Moreover, the adaptability of shed frame structures allows for a range of insulation options and energy-efficient materials, which can significantly enhance their thermal performance. This makes them suitable for various climates and conditions, providing comfort while minimizing energy consumption.

shed frame structure

Over the past few decades, metal has emerged as a preferred choice for construction. Its inherent properties, such as resistance to pests, fire, and extreme weather conditions, make it an ideal option for various applications. Whether it’s for residential, commercial, or industrial projects, metal building materials like steel, aluminum, and copper offer longevity and sustainability that wood and concrete cannot always provide. As the construction industry continues to embrace green building practices, metal is often recognized for its recyclability, further enhancing its appeal.

When it comes to protecting your vehicles and enhancing your property, red barn metal carports offer an excellent solution that blends both aesthetic appeal and practical utility. These structures are becoming increasingly popular among homeowners who seek not only functional coverage for their automobiles and equipment but also a distinctive and charming architectural style reminiscent of traditional barns.

With a metal garage, maintenance becomes a breeze. Traditional garages often require regular upkeep like painting, sealing, and repairing damaged wood, which can be time-consuming and costly. On the other hand, metal garages typically only need occasional washing and inspections to ensure that everything is in good condition. Additionally, many metal garages come with pre-coated finishes that resist paint chipping and rust, further reducing the maintenance burden.

A slim metal shed can also enhance your property’s overall value. As prospective buyers look for homes that offer practical solutions to common challenges, the inclusion of a well-constructed shed can be a major selling point. It showcases your ability to utilize space effectively while demonstrating a commitment to organizing and maintaining your property.

Industrial storage buildings serve as a backbone for numerous sectors, providing essential spaces for storing, managing, and distributing goods and materials. As the economy continues to evolve with increased manufacturing, e-commerce, and global supply chains, the demand for specialized storage facilities has surged. This article explores the importance, design considerations, and the future trends associated with industrial storage buildings.

In recent years, the concept of combining a functional workspace with comfortable living spaces has gained immense popularity. Among the most innovative solutions to this practical challenge is the metal garage with living quarters. This unique structure merges the durability and strength of metal construction with the comforts of home, making it an ideal choice for various needs, whether for families, hobbyists, or those seeking a sustainable lifestyle.

Moreover, steel barn houses contribute to a sense of community and connection to the landscape. Many people choose to build these homes in rural settings, where they can enjoy expansive views and a close-knit atmosphere. The large open spaces often encourage outdoor activities and foster a lifestyle that embraces nature, from gardening to hosting family gatherings around fire pits. This connection to the land and community aligns with a growing trend towards minimalism and simpler living.

In conclusion, a mini metal shed is an excellent investment for those seeking an effective storage solution. Its durability, security, space efficiency, low maintenance, and customizable features make it a top choice for homeowners looking to optimize their storage capabilities. Whether you are a gardening enthusiast needing a place for tools or a homeowner looking for organized outdoor storage, a mini metal shed provides the perfect blend of functionality and style. With its various sizes and designs, it’s easy to find the ideal shed to meet your specific needs, making cluttered outdoor spaces a thing of the past.

Steel Span Building Factories Revolutionizing the Construction Industry

7. Adaptability to Zoning Laws Because of their smaller footprint, a 30x30 prefab building may be easier to fit into various zoning regulations and building codes than larger structures. This adaptability can expedite the approval process, making it a viable option for those looking to expand their property or start a new venture.

The Importance of Farm and Agricultural Buildings

Beyond their functionality, red iron barns stand as a testament to the evolution of farming practices. In an era when modern technology dominates agricultural methods, these traditional structures remind us of the hard labor and perseverance that defined the farming community. Each barn tells a story of the people who built and maintained it, reflecting their hopes, struggles, and achievements. Many barns have been passed down through family lines, burdened with the weight of history and the promise of the future.

When comparing the costs of building and maintaining a barn, metal structures often prove to be more cost-effective in the long run. Though the initial investment may be higher than wood, the low maintenance requirements and extended lifespan contribute to significant savings over time. Additionally, many metal barn manufacturers offer financing options, making it easier for horse owners to invest in a quality structure without breaking the bank.

Moreover, metal buildings can be customized to meet the specific needs of a farm. Whether a farmer requires a simple storage shed for tools or a large barn to house equipment, metal buildings can be designed to suit various dimensions and functionalities. Options for high ceilings and wide doors enhance accessibility for larger machinery, while added features such as insulation, ventilation, and lighting can be incorporated to create an efficient working environment.

The Rise of Industrial Warehouse Construction Trends and Innovations

Maximizing Space

· With a lifespan of 50 years or more, steel buildings are a long-term investment that will provide a secure and durable storage solution for years to come.

Commercial metal garages offer a high degree of versatility, making them suitable for various applications. Whether you need a workshop, storage facility, retail space, or even a manufacturing unit, these garages can be tailored to your specific requirements. Customization options are abundant, ranging from size and shape to features such as windows, doors, and insulation. This flexibility allows businesses to create a functional environment that aligns with their operational needs.

commercial metal garage

1. Size Determine what size shed best fits your needs. Consider storing equipment, workspace requirements, or if you plan to use the shed for hobbies.

One of the most compelling advantages of a narrow metal shed is its design tailored for limited spaces. Urban living often means dealing with small yards and restricted outdoor areas. Traditional wooden sheds can be bulky, taking up significant space and not fitting well in tight spots. In contrast, a narrow metal shed offers a streamlined silhouette that allows homeowners to utilize every square inch of their property efficiently. Whether placed alongside a fence, against the side of a house, or nestled in a corner of the yard, these compact structures can seamlessly integrate into the landscape without overwhelming it.