The electrical control box, on the other hand, is what?

Users can operate and monitor a piece of equipment using a Control Box, a physical interface. A container housing the mechanism or device that regulates and controls anything (mainly electrical or radio waves) within a system.

An electrical control box is analogous to a human body: Our bodies have essential organs that regulate and monitor our environment. Control panels for mechanical processes are similar in that they contain crucial electrical equipment for controlling and electronically monitoring the operation. Industrial equipment and machinery require well-defined functions and systematic control to meet diverse process objectives. In manufacturing equipment, control boxes provide these roles.

STRUCTURE OF CONTROL PANELS

The construction of a control panel consists of an enclosure and numerous distinct types of electrical components. These components define and arrange the various functions carried out by the control panel. These components include:

It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities

It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities floor marking tape. The ease of application and removal allows for quick adaptation to changing guidelines and protocols.

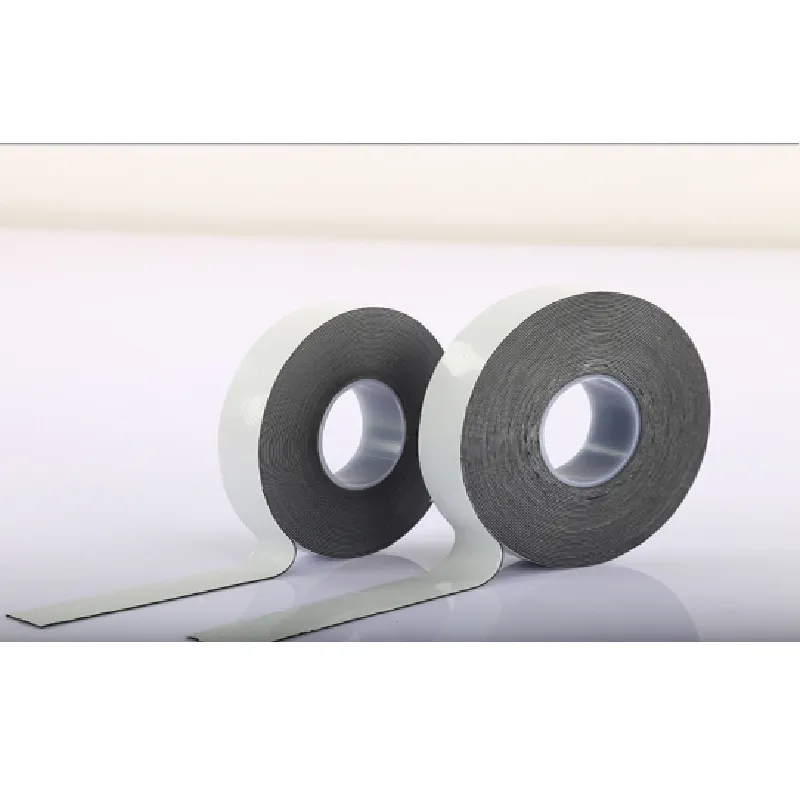

floor marking tape. The ease of application and removal allows for quick adaptation to changing guidelines and protocols.The key feature of amalgamating rubber tape is its ability to effectively bond to itself when stretched and wrapped around an object. This self-amalgamating characteristic creates a strong and durable seal that is resistant to water, chemicals, UV rays, and extreme temperatures. As a result, this tape is widely used for electrical insulation, plumbing repairs, cable management, and automotive applications.

3. Durability Self-fusing silicone tape boasts excellent durability and tensile strength. It endures significant wear and tear without losing functionality, making it ideal for both temporary and permanent repairs.

self fusing silicone electrical tape

Butyl Rubber Tape

What is Black Flex Tape?