cattle wire mesh fencing

Latest articles

In addition, when using the steel wire, it is also necessary to pay attention to protecting the surface of the steel wire. For example, if the surface of the steel wire is damaged or corroded, it may affect its electrical conductivity. Therefore, in the use of steel wire, should try to avoid steel wire with wet environment or chemical substances in order to protect its surface and electrical conductivity.

cattle wire mesh fencing...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read More

cattle wire mesh fencingAfter annealing, the wire will become soft, flexibility will increase, iron is a relatively active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements in dry air. Its production cost is lower, its use and scale are also relatively wide, and it has better protective function. Therefore, it is an important material for steel parts in strict working environment.

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read Morecattle wire mesh fencing

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read Morecattle wire mesh fencing

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read Morecattle wire mesh fencing

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read More

cattle wire mesh fencingCold wire drawing is mainly used in the production of hardened low carbon steel wire, with a diameter of 8 mm steel bar to play a fixed role in the development of the construction industry has played a role in promoting the development of the construction industry, widely used. The bonding and anchorage performance between cold wire drawing and concrete is good. When used in components, the phenomenon of cracking in the anchorage area of components and damage caused by steel wire slip is fundamentally eliminated, and the bearing capacity and anti-cracking capacity of the end of components are improved.

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read More

cattle wire mesh fencingIf it is not packaged, then a car of blade thorn rope can not be loaded with many pieces, and it is also relatively occupied and easy to lose in the transportation process. The number of the packed blade thorn rope is 50 bundles, and the volume is reduced after hydraulic compression so that it is more convenient to load and unload, and the forklift can easily load and unload. Under normal circumstances, when exporting, the blade thorn rope will be packaged and sold, so that the volume occupied in the container is relatively small, which can be easily placed and will not occupy much place.

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read Morecattle wire mesh fencing

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read Morecattle wire mesh fencing

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read Morecattle wire mesh fencing

...

cattle wire mesh fencing 【cattle wire mesh fencing】

Read More

Popular articles

- With the progress of the anti-corrosion skills of the cattle fence, the steel wire function of the cattle fence will also improve, so that the life of the progress of the use of great help. The number of years of use is primarily dependent on the environment of use and whether the operation of the construction is standard at the time. The operation standard of progress operation can also extend the number of years of use. The above is a general estimate of the life of the cattle net, I hope to help you.

Common galvanized iron wire equipment is usually used in barbecue net, barbecue net generally requires to have a long service life, with galvanized iron wire equipment to wire a layer of zinc, barbecue net is not easy to be corroded.

Post time: 07-05-22Cold galvanizing (galvanizing) is in the plating tank after the current unidirectional, so that the zinc gradually plated on the metal surface, slow production speed, uniform coating, thin thickness, usually as long as 3-15g, bright appearance, poor corrosion resistance, usually a few months will rust. Compared with hot dip galvanizing, the production cost of electric galvanizing is lower.

Latest articles

-

-

Large roll galvanized wire as a common industrial supplies in daily life, many people will use, but many of them are not standard operation. Cold galvanized wire is one of the many categories of iron wire, widely used, cold galvanized wire is a kind of galvanized iron wire products made of high quality low carbon steel wire processing, after drawing forming, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes.

-

4, galvanized can be used zincate galvanized or chloride galvanized process, should use appropriate additives to meet the requirements of this standard coating.

-

-

The corrosion or discoloration of galvanized iron wire in the atmosphere caused by oxygen, moisture and other pollution impurities is called rust or rust. After galvanized iron wire rusting, it will affect the appearance quality, seriously affect the use, and even cause scrap, so galvanized iron wire must be properly kept and pay attention to rust prevention.

-

No matter how old dogs are, they seem to love to touch noses with people and other animals. In fact, dogs touch noses as a way of socializing, just like humans shake hands and hug when they meet. But dogs don’t nuzzle every human or every animal. They pick and choose who to nuzzle. If they don’t like you, or don’t know you at all, they won’t touch your nose. However, adult dogs will touch almost every puppy’s nose, and they will not only touch the puppy’s nose, but also smell the puppy’s body.

Polyacrylate oil seals are a perfect compromise between quality and cost. They perform well with high temperatures and chemicals, but not as well as Viton oil seals. Polyacrylate has a temperature range of -25 degrees Fahrenheit to 300 degrees Fahrenheit. Due to their outstanding resistance to hot oil and oxidation, they are commonly used in automobile transmissions and hoses; however, they are also used for shaft seals, gaskets, and o-rings.

Make sure that the new gasket is clean, and confirm which way round it fits. The upper side is usually marked 'top', 'haut' or 'oben'.

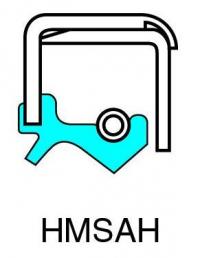

1) Common seal types and their features

Runout must be kept to a minimum. Movement of the center of rotation is usually caused by bearing wobble or shaft whip. When coupled with misalignment, this problem is compounded. Contrary to popular belief and common practice, the installation of flexible couplings cannot correct or compensate for misalignment.

Silicone

Wide temperature range

Commonly used in low temperature applications

Very prone to mechanical damage during fitting

Ultimately, oil seals are devices that help to exclude dust and dirt, etc., while at all times retaining the lubricant in the piece of equipment.

Oil seal type or shape

Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine

Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine br9es spark plug. However, the BR9ES Spark Plug is designed with a rugged construction that can withstand the harshest operating conditions, resulting in longer service intervals and reduced maintenance costs for vehicle owners.

br9es spark plug. However, the BR9ES Spark Plug is designed with a rugged construction that can withstand the harshest operating conditions, resulting in longer service intervals and reduced maintenance costs for vehicle owners.Polyacrylate (ACM) Oil Seals

Almost every lip seal is constructed to have a flexible inner part that creates a dynamic seal on the moving shaft, as well as a hard outer casing that statically matches the machine-end cover. The flexible part is made from different grades of rubber, while the hard part is made of light-gauge metal or strong plastic.