welded wire mesh for rabbit cages

Latest articles

welded wire mesh for rabbit cages

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read Morewelded wire mesh for rabbit cages

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read Morewelded wire mesh for rabbit cages

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read More2. The positive and negative twisting barbed wire is cost-effective

welded wire mesh for rabbit cages...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read More

welded wire mesh for rabbit cagesThis method is generally the use of hot rolled laminated plate as raw material, the annealed steel plate is first sent to the pickling workshop, with sulfuric acid or hydrochloric acid to remove the surface of the steel sheet oxygen hot galvanizing method. After pickling, the steel plate immediately enters the tank to soak and wait for galvanized, which can prevent the reoxidation of the steel plate. After pickling, water cleaning, squeeze dry, drying, into the zinc pot, the temperature has been maintained at 445-465℃.

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read Morewelded wire mesh for rabbit cages

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read More

welded wire mesh for rabbit cages1. Zinc pot operators must stick to their posts

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read Morewelded wire mesh for rabbit cages

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read Morewelded wire mesh for rabbit cages

...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read More

welded wire mesh for rabbit cages

Post time: 15-09-22...

welded wire mesh for rabbit cages 【welded wire mesh for rabbit cages】

Read More

Popular articles

- The first difference is in the amount of zinc.

Post time: 29-12-22Widely used in practice, iron wire also has certain harm, simple rust and corrosion, so we can generally use galvanized method to prevent product corrosion. Together in addition to this method, metal commonly used treatment methods and phosphating treatment, oxidation treatment, etc. Metal phosphating treatment: iron and steel products to remove oil, rust, into the specific composition of the salt solution soak, you can form a layer of water soluble salt film on the surface of the metal, this process is called phosphating treatment.

Latest articles

-

-

-

In addition to these reasons, we should pay attention to the tooling and process must be stable, and regular testing should be done to ensure the uniformity of galvanized layer.

-

In addition, before the wire enters the zinc liquid, a layer of insulation material containing zinc oxide reducing agent can reduce the heat loss and zinc ash floating. When the zinc solution contains 0.002%-0.005% aluminum, the brightness of the zinc layer can be increased obviously, and excessive zinc ash can be prevented from oxidation on the surface of the zinc solution.

-

Then are there other barbed rope products with the same ability to prevent corrosion at a lower price? The answer is yes, the latest zinc-aluminum alloy barbed rope developed by our factory is a relatively new type of barbed rope products, which has anti-corrosion anti-aging ability can effectively prevent rust aging of barbed rope, at the same time the price is lower than stainless steel barbed rope, only half of it.

-

The use of PowerShell cmdlets makes these operations highly scriptable, enabling automation of repetitive tasks The use of PowerShell cmdlets makes these operations highly scriptable, enabling automation of repetitive tasks

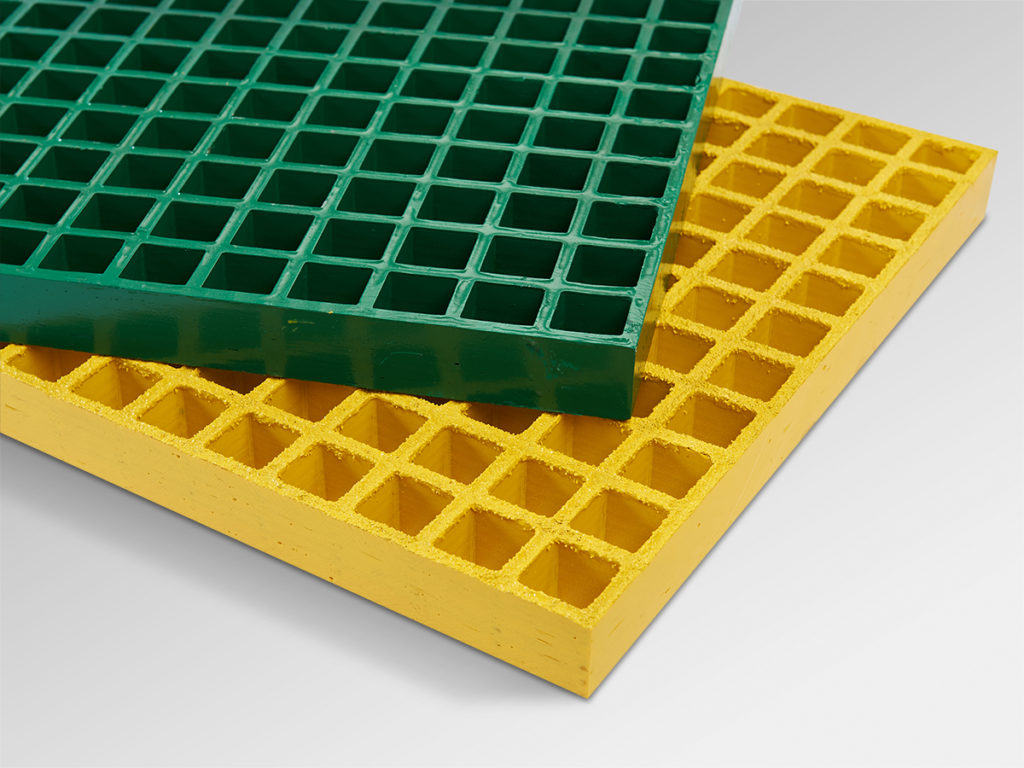

The use of PowerShell cmdlets makes these operations highly scriptable, enabling automation of repetitive tasks The use of PowerShell cmdlets makes these operations highly scriptable, enabling automation of repetitive tasks grp shell.

grp shell.

Available in the full range of resins offered for molded products, Micro-Mesh surface options are concave meniscus, optional smooth (sanded) surface, or optional coarse or fine grit surfaces.

Our fiberglass structural shapes and pultruded fiberglass profiles are made from a combination of fiberglass and thermosetting resin systems. All shapes are lightweight, impact resistant, low maintenance, non-magnetic, low conductive, and have dimensional stability, making them easy to install and ideal for several applications. Custom shapes are available upon request. For more on fiberglass structural shapes, click here.