water filter mesh screen

Latest articles

water filter mesh screen

...

water filter mesh screen 【water filter mesh screen】

Read Morewater filter mesh screen

...

water filter mesh screen 【water filter mesh screen】

Read More

water filter mesh screenThe weight calculation method of hexagonal net is: the weight calculation method of hexagonal net: silk meridian.× silk meridian.× base x length x width ÷2=kg base: 1/2′=2.151′=1.273/4′=1.65/8′=1.875/4′=1.091′x1/2′ : 3′=0.4 silk warp. x silk warp. X 2x length x width ÷8×3=kg

...

water filter mesh screen 【water filter mesh screen】

Read MoreThe second is price.

water filter mesh screen...

water filter mesh screen 【water filter mesh screen】

Read Morewater filter mesh screen

...

water filter mesh screen 【water filter mesh screen】

Read Morewater filter mesh screen

...

water filter mesh screen 【water filter mesh screen】

Read Morewater filter mesh screen

...

water filter mesh screen 【water filter mesh screen】

Read More

water filter mesh screenThe error of construction welding net diameter should be controlled at 0.02 mm. For example, we buy wire diameter of 89 wire welding net, with a micrometer to measure the diameter, the diameter of the allowable range is 87 -91 wire. In this range is qualified welding net. Because the accuracy has been compared, but no one can control it so well in the production process. The welding net can be accurate to 0.01 mm, so the error is allowed.

...

water filter mesh screen 【water filter mesh screen】

Read MoreHeavy hexagonal mesh is made of low carbon steel wire galvanized large wire braided, the tensile strength of steel wire is not less than 38kg/m2, the diameter of steel wire can reach 2.0mm-3.2mm, the surface of steel wire is usually hot galvanized protection, galvanized amount can reach 500g/m2.

water filter mesh screen...

water filter mesh screen 【water filter mesh screen】

Read MoreHeavy hexagonal net is made of low carbon steel wire galvanized large wire braid, the tensile strength of the steel wire is not less than 38kg/m2, the diameter of the steel wire can reach 2.0mm-3.2mm, the surface of the steel wire is usually protected by hot dip galvanizing, the amount of galvanizing can reach 500g/m2.

water filter mesh screen...

water filter mesh screen 【water filter mesh screen】

Read More

Popular articles

Large hexagonal net called stone cage net, mainly used for mountain preparedness protection, hydraulic construction, etc. Small wire hexagonal net is used as a good material for breeding, will twist the hexagonal net in the welding of the iron frame on the hexagonal net welding into chicken cage, pigeon cage, rabbit cage and other cage, hexagonal net is an excellent material for breeding with the net.

Iron products are common metal products in life. Iron products appear everywhere in our life, but there is a big problem in using iron products. Iron products will rust, and when rust occurs, it will affect the use and appearance of iron products. Adding non-metallic coating: clean, dry and coat the surface of iron and steel products with a layer of protective materials, such as oil, mineral grease, rust-proof grease, plastic and lacquer.

The application of cold wire drawing is very wide today. What problems need to be paid attention to in the acceptance of cold wire drawing in galvanizing plant?

Are you familiar with galvanized silk mesh? Do you know what to pay attention to in the process of use?

Latest articles

-

With a large pickpocket used for steel wire, into the zinc liquid before the surface of the zinc ash stirring; Use a small outlet for galvanized steel wire; Zinc pot steel wire outlet in 30 minutes, with pickpockets back and forth, until the large, floating zinc residue into brown, real zinc ash, zinc ash surface. The extracted zinc ash should be brown yellow real zinc ash, zinc surface, effectively reduce zinc consumption.

-

There is still some demand for galvanized barbed rope by daily residents, but often the quantity is not particularly much. If the barbed rope factory delivers goods, then the extra freight may be higher than the price of the customer to buy the barbed rope in the market. The thorn rope factory sells to customers who buy in large quantities. There is a lot of demand for it, and it also hopes to find a manufacturer to purchase. Customer procurement problems can be much more complete introduction in the thorn rope factory, but also let customers more at ease.

-

As we all know, the mechanism of resistance to atmospheric corrosion of zinc includes mechanical protection and electrochemical protection. Under the condition of atmospheric corrosion, there are ZnO, Zn(OH)2 and basic zinc carbonate protective film on the surface of zinc layer, which to a certain extent slows the corrosion of zinc. When this protective film (also known as white rust) is damaged, a new film will be formed.

-

-

The hook mesh is a good material for flood control and flooding. Can also be used for arts and crafts manufacturing, mechanical equipment transport network mountain beautification network – high strength steel wire grid (hook mesh, diamond mesh) hook mesh mountain protection application principle, hook mesh interests, mesh uniform, flat, woven concise, hook woven, beautiful and generous, net, net width, wire diameter is thicker, not easy to corrosion, long life, strong usefulness.

-

Galvanized wire is processed by low carbon steel wire rod. It is made of low carbon steel, after drawing forming, pickling and rust removal, high temperature annealing, hot dip galvanizing, cooling and other processes. Electrogalvanized iron wire using low carbon steel as raw materials, after drawing, galvanized and other processes completed. It has the characteristics of galvanized layer, strong corrosion resistance, strong galvanized layer, and so on. Galvanized iron wire is widely used in construction, highway walls, Zahua, weaving and other industries.

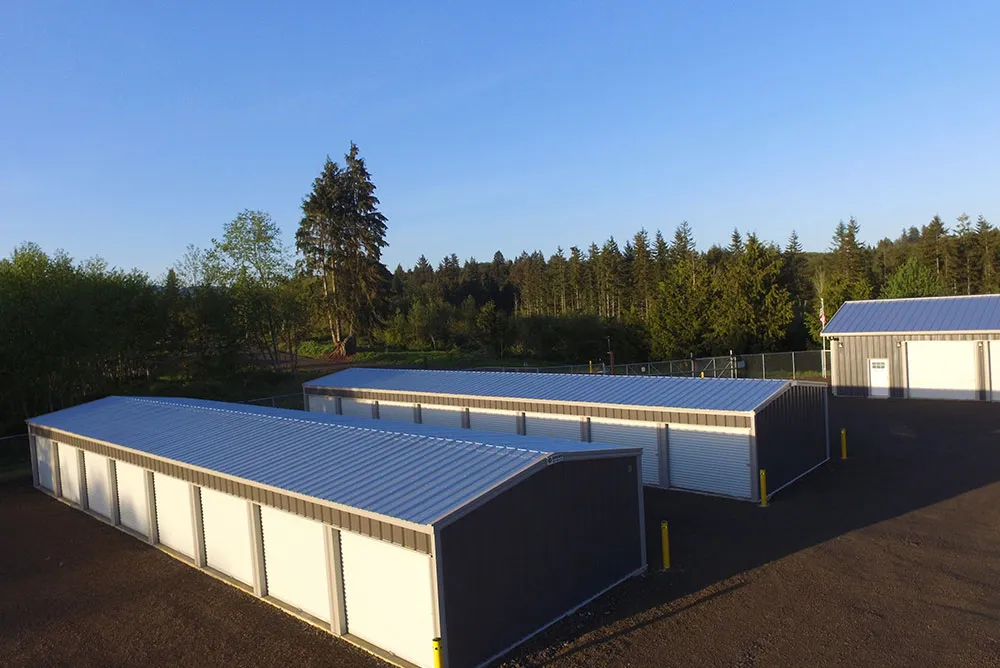

Factory Direct Steel Buildings A Smart Choice for Your Construction Needs

In summary, the 8x8 metal shed with a floor is an excellent solution for those seeking a reliable and aesthetically pleasing storage option. Its combination of durability, security, and low maintenance makes it suitable for various uses, from gardening to general storage. As homeowners look to maximize their outdoor spaces, opting for a metal shed is a decision that promises satisfaction and functionality for years to come. Whether you're an avid gardener, a DIY enthusiast, or simply in need of extra space, an 8x8 metal shed is sure to meet your needs effectively.

The Advantages of Prefab Metal Storage Buildings

Steel structures have gained popularity for numerous reasons. First and foremost, steel is renowned for its strength and resilience. Unlike traditional wood or concrete, steel can withstand extreme weather conditions, resist pests, and is less likely to warp or crack over time. This durability makes steel an excellent choice for a variety of structures, from industrial buildings to high-rise apartments.

Protection from Environmental Elements

What is a 12x20 Metal Garage Kit?

Another significant advantage of custom metal garages is their durability. Constructed from high-quality steel, these buildings can withstand harsh weather conditions, including heavy snow, strong winds, and extreme temperatures. Unlike wood, metal is not susceptible to pests, rot, or rust when treated properly, ensuring that your garage maintains its integrity over the years. This durability translates to lower maintenance costs and longer lifespans, making metal buildings a wise investment for the future.

Cost-Effectiveness

One of the primary benefits of all steel sheds is their unparalleled durability. Unlike wooden sheds that are susceptible to rot, pest infestations, and weather damage, steel sheds are built to withstand the elements. They can endure harsh weather conditions, from heavy rain to snow, and are resistant to fire, rust, and corrosion. This reliability ensures that whatever is stored inside remains protected and secure.

Installation Considerations

In conclusion, an 8x8 metal shed represents an outstanding investment for anyone looking to enhance their property’s storage solutions. With their durability, security, low maintenance needs, versatility, aesthetic appeal, easy installation, and cost-effectiveness, these sheds provide an efficient way to organize tools, equipment, and personal belongings. Whether you’re a gardener, DIY enthusiast, or just need some extra space, an 8x8 metal shed is a practical addition that will serve you well for years to come.

Exploring the Charms of Red Barn Metal Buildings

In an age where sustainability is increasingly vital, industrial metal storage sheds present an environmentally friendly option. Metal is a recyclable material, and many manufacturers utilize recycled content in their products. Choosing metal storage solutions not only reduces the demand for new raw materials but also contributes to a circular economy. Additionally, these sheds can often be designed for energy efficiency, with options such as natural lighting and insulation to minimize energy consumption.

The global push toward sustainable farming practices has led many poultry farmers to consider eco-friendly alternatives. Steel is a recyclable material, making it an environmentally responsible choice for poultry housing. By opting for steel sheds, farmers can contribute to sustainability efforts while benefiting from the lower carbon footprint associated with metal structures. Moreover, modern steel poultry sheds can incorporate energy-efficient systems, such as natural lighting and solar panels, further enhancing their sustainability.

Finally, building a sustainable farm involves engaging with the local community. Sharing knowledge through workshops, farm tours, and educational programs can inspire others to adopt sustainable practices. Collaborating with local organizations can also provide support and resources necessary for success.

Understanding Steel Warehouse Building Prices

Versatility in Design

Before diving into the design and construction of your metal garage workshop, the first step is selecting an appropriate location. Consider factors such as accessibility, local zoning laws, and proximity to utilities. A flat, well-drained area is ideal to prevent water pooling and foundation issues. Additionally, think about the noise and traffic that might affect your neighbors. Ensuring a sufficient distance from residential areas can maintain harmony in your community.

Conclusion

Environmental Considerations

5. Location and Site Conditions

Metal has been a cornerstone of industrial development since the dawn of the industrial revolution. Its strength, durability, and versatility make it an ideal material for factories, especially in settings where heavy machinery and large-scale production are fundamental. Metal factory buildings are designed to accommodate the rigorous demands of production lines, housing everything from welding stations to assembly lines.

5. Eco-Friendly Option

Environmentally Friendly

Additionally, consider the size and layout of the barn you need. Take into account the purpose of the barn, whether it's for storage, agriculture, or leisure, and plan accordingly. Many suppliers offer design services to help you create a functional space that meets your requirements.

Furthermore, suppliers typically have established relationships with various manufacturers, allowing them to source high-quality materials at competitive prices. This capability not only enhances the quality of the final product but also ensures that projects stay within budget.

Forklifts transporting inventory don’t have to maneuver around columns. Pallet racks can extend up to the ceiling. Production lines can function anywhere without a column blocking access to the control panel.

As urban populations continue to grow, the demand for fresh produce and sustainable food sources has never been greater. Traditional agriculture is increasingly challenged by limitations such as land availability, water scarcity, and the carbon footprint of transporting food over long distances. In response to these challenges, the concept of agriculture in buildings, also known as vertical farming, has emerged as a promising solution. This innovative approach combines architecture with agriculture, utilizing the often underutilized space within urban buildings to produce food locally.

Additionally, steel warehouses can be constructed more quickly than those built with traditional materials. Prefabrication techniques enable sections of the warehouse to be fabricated off-site, reducing on-site construction time and allowing businesses to start operations sooner. This rapid deployment is a significant advantage, particularly in industries where time is of the essence, such as e-commerce and manufacturing.

steel storage warehouse

A steel portal shed consists of a series of framed structures typically made from high-quality steel. The design is characterized by its clear-span openings, meaning that the internal space is unobstructed by columns or beams. This feature makes steel portal sheds particularly suitable for environments where maximum space is required for storage or industrial activity. They can be constructed in various sizes and configurations, tailored to meet specific functional needs.

One of the most significant benefits of steel buildings is their durability. Steel is known for its high strength-to-weight ratio, which means that it can support heavy loads while being relatively lightweight. This attribute makes steel buildings resistant to the types of structural failures that may plague other materials, such as wood or concrete. Steel structures are versatile enough to withstand extreme weather conditions, including high winds, heavy snowfall, and seismic activities, ensuring the safety and longevity of the facility.

Additionally, metal sheds require minimal maintenance compared to wooden ones. A simple wash with soap and water is often enough to keep the exterior looking pristine. Many metal sheds are also treated with protective coatings to prevent rust, adding to their longevity.

Furthermore, sheds can also increase the value of the farm property. Prospective buyers often look for well-developed facilities that can support modern agricultural activities. A well-constructed agricultural shed can be a significant selling point, making the property more attractive to investors and buyers.

Additionally, modern steel factories can implement energy-efficient designs, including natural lighting systems, advanced HVAC systems, and insulation technologies, reducing overall energy consumption. These features not only contribute to lower operational costs but also enhance the comfort and productivity of workers.

Conclusion

The Steel Beam Barn A Fusion of Strength and Style

Understanding Steel Beam Costs

The Raised Center Aisle Metal Barn A Modern Solution for Farm and Storage Needs

Cost-Effectiveness

Prefab metal storage buildings are pre-engineered structures made from steel or other metal materials that are manufactured off-site and then assembled on-site. This method of construction significantly reduces the time required for completion compared to traditional building methods. The prefabricated components are manufactured in controlled environments, ensuring high quality and precision.

Enhanced Security

As industries continue to evolve, the trend towards factory metal buildings is likely to grow. The combination of durability, cost-effectiveness, rapid construction, customization options, and sustainable practices make metal buildings an attractive option for businesses across various sectors. Whether for a new manufacturing facility, a distribution center, or an expansion of existing operations, factory metal buildings represent a modern solution tailored to meet the challenges of today’s industrial demands.

In recent years, residential steel frame construction has gained popularity as a reliable and efficient method for building homes

. Traditionally, wood has been the primary material used in residential construction, but the advantages that steel offers are compelling architects, builders, and homeowners to consider this alternative.Safety and compliance cannot be overlooked in industrial shed design. Employers must prioritize the safety of their workers by incorporating safety features such as adequate fire exits, emergency lighting, and proper ventilation systems. Regular safety audits and adherence to health regulations are critical to maintaining a safe working environment.

Sustainability