what size drywall screw for 5 8 drywall

Latest articles

what size drywall screw for 5 8 drywall

...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read More

what size drywall screw for 5 8 drywallCold galvanizing is in the plating tank through the current unidirectional zinc gradually plated on the metal appearance, the production speed is slow, uniform coating, thin thickness, usually only 3-15 microns, bright appearance, smooth, high aesthetics, poor corrosion resistance, generally a few months will rust. Hot dip galvanized coating is thicker, generally 30-60 microns, coating corrosion resistance is higher. Suitable for outdoor work of steel parts, such as highway fences, power towers, large size fasteners and other more “rough” workpiece long-term rust prevention.

...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read More

what size drywall screw for 5 8 drywall

Post time: 17-10-22...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read Morewhat size drywall screw for 5 8 drywall

...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read Morewhat size drywall screw for 5 8 drywall

...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read More2, galvanized wire mesh molding sheet storage ground should be flat, according to the symbolic requirements of the accumulation of regular, height should not exceed 2M, and away from heat sources, avoid exposure.

what size drywall screw for 5 8 drywall...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read Morewhat size drywall screw for 5 8 drywall

...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read MoreHot dip galvanizing is also called hot dip zinc and hot dip galvanizing: it is an effective way of metal anticorrosion, mainly used in various industries of metal structure facilities. It is to immerse the steel parts after rust removal into zinc solution melted at about 500℃, so that the surface of the steel members is attached with zinc layer, so as to play the purpose of anticorrosion.

what size drywall screw for 5 8 drywall...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read More

what size drywall screw for 5 8 drywall

Post time: 17-04-23...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read More

what size drywall screw for 5 8 drywallIn order to make the zinc content of steel wire stable in the future, and maintain its uniformity, as far as possible to reduce the zinc content, and effectively reduce zinc consumption to the actual work, the following measures are proposed by the wire factory:

...

what size drywall screw for 5 8 drywall 【what size drywall screw for 5 8 drywall】

Read More

Popular articles

- But there are some necessary precautions in the production of galvanized wire. Remove all tools and piles on the work site and equipment that hinder activities, and slowly put the wire into the cylinder during pickling to prevent acid splashing on the body. When adding acid, the acid must be slowly poured into the water. Do not pour water into the acid to prevent acid spillage and injury. Workers should wear protective glasses when working. Then in the handling of wire and other items, it is strictly prohibited to push hard.

Then are there other barbed rope products with the same ability to prevent corrosion at a lower price? The answer is yes, the latest zinc-aluminum alloy barbed rope developed by our factory is a relatively new type of barbed rope products, which has anti-corrosion anti-aging ability can effectively prevent rust aging of barbed rope, at the same time the price is lower than stainless steel barbed rope, only half of it.

The application of electric welding mesh is more widely, at present, it has replaced the use of other parts of the screen, the cost of electric welding mesh is low, the production speed is very fast, so it is very popular. The treatment required before galvanized welding mesh is recrystallization annealing, because the welding mesh must maintain an oxide and no other impurities of pure iron active surface, if you can’t keep its surface clean will lead to poor galvanized effect, galvanized layer and iron material is not tightly combined, so this step is necessary.

Different from the general zinc barbed rope, high zinc barbed rope surface zinc content is very high can reach the former 6-8 times, so in the service life also has a great advantage, ordinary products three or five years began to corrosion and the latter will take longer to change. Stainless steel barbed rope is in the material aspect of protection, so the durability is also better, these two products are long in the service life, but in the price is high.

Latest articles

-

-

-

After annealing, the wire will become soft, flexibility will increase, iron is a relatively active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements in dry air. Its production cost is lower, its use and scale are also relatively wide, and it has better protective function. Therefore, it is an important material for steel parts in strict working environment.

-

2, mesh, mesh also directly affects the price of the stone cage net

-

Galvanized hexagonal mesh uses: building wall fixed, heat preservation, heat insulation; Power plant piping, boiler heating; Anti-freezing, residential protection, landscaping protection; Raise chicken and duck, isolate chicken and duck house, play the role of protecting poultry; Protect and support seawalls, hillsides, roads and Bridges and other waterworks.

-

Links

- The Essential Role of Expansion Joint Foam Strips in Construction and Engineering

- In the world of electrical work, having the right tools is crucial for ensuring safety and efficiency. One such tool that has become an essential part of any electrician's toolkit is coloured electrical tape. This versatile product not only helps to identify wires and cables but also serves as a protective coating against damage and corrosion.

- 3. Silicone Rubber Tape Silicone rubber tape is a high-performance insulating tape that is resistant to extreme temperatures, chemicals, and UV radiation. It is commonly used in high-voltage applications and harsh environments.

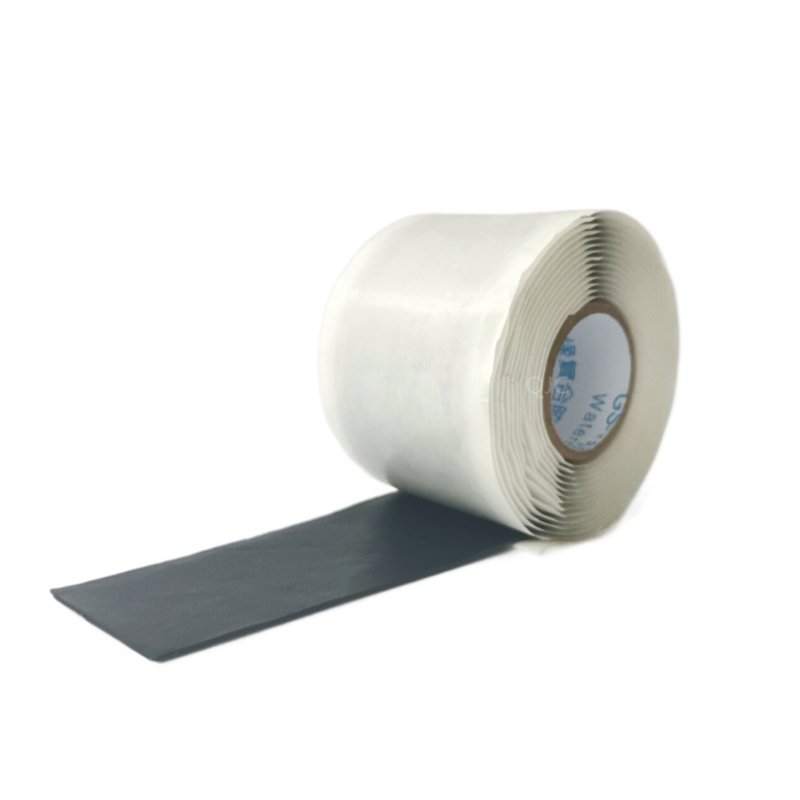

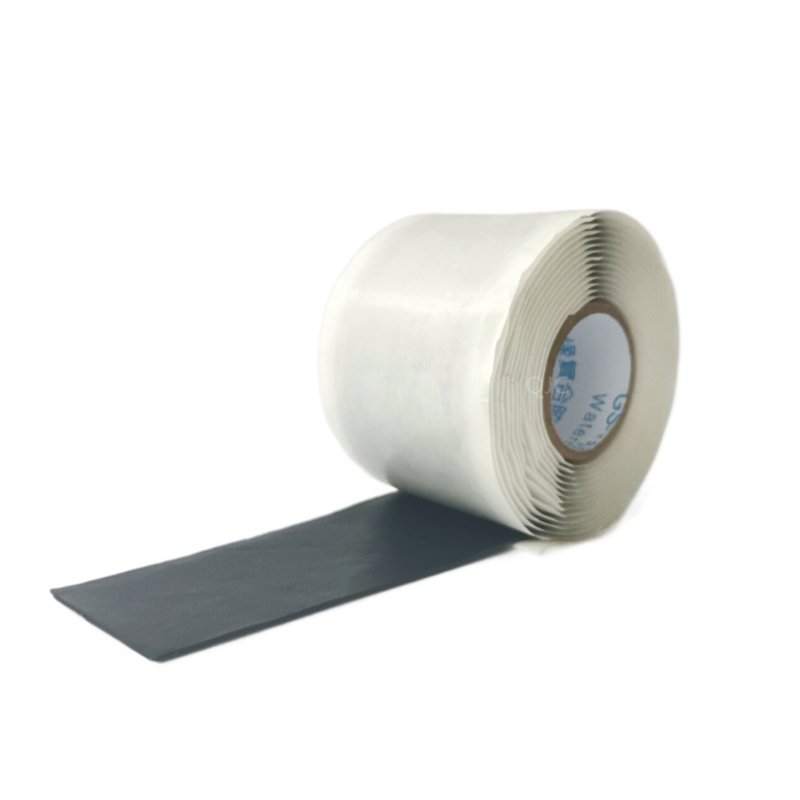

- One of the key advantages of self-amalgamating electrical tape is its ability to bond and seal itself upon application. Unlike traditional tapes that require additional steps such as applying heat or solvents, this tape forms a strong bond as soon as it is wrapped around a cable or connector. This makes it particularly useful for temporary fixes or emergency situations where speed is of the essence.

we supply self-amalgamating tape manufactured from ethylene propylene rubber which is weatherproof and rugged enough to cope with the demands of most applications, including roofing and sailing where it is used as rigging tape. There are silicone self-amalgamating tapes which offer a slightly higher voltage rating than ethylene propylene rubber but these offer much poorer tear resistance.

CONTROL PANEL MAINTENANCE

Electrical tapes are versatile, suited to a multitude of tasks, and when installed properly provide a long-term, effective insulation. According to Anderson, both the NJATC headquarters and local training efforts are strongly supported by industry suppliers, which provide sample products and assist with course development and hands-on instruction. In addition, manufacturers of electrical-grade tapes are generally willing to provide technical support and instruction on proper taping techniques.

The Versatility of Self-Adhesive Insulation Tape

Goodman is a technical service engineer and Brown is a technical service senior engineer with 3M in Austin, Texas.

In the industrial landscape, control boxes are the linchpins of efficiency and safety. Here’s how:

Silicone and Self-Amalgamating Tape Buyer's Guide

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations yellow and green electrical tape.

yellow and green electrical tape.Furthermore, butyl rubber strip exhibits excellent chemical resistance, making it suitable for use in environments where exposure to oils, acids, and solvents is common. Its ability to withstand a wide range of chemicals without degradation or loss of performance makes butyl rubber strip a valuable material for sealing and gasket applications in industrial settings.

To use amalgamating tape effectively, follow these simple steps