soft black iron wire

Latest articles

soft black iron wireGalvanized silk hook mesh is widely used in warehouses, east and west refrigeration, protective reinforcement, park, zoo fence, Marine fishing fence and construction site fence, machinery and equipment protection. There are two kinds of use, that is, slope protection hook net (slope protection net), coal mine hook net (mine hook net, coal mine support net, roadway support net).

...

soft black iron wire 【soft black iron wire】

Read Moresoft black iron wire

...

soft black iron wire 【soft black iron wire】

Read More⑹ can not open the groove 1 ~ 6mm thick metal sheet single-side welding double-sided forming.

soft black iron wire...

soft black iron wire 【soft black iron wire】

Read More

soft black iron wireWith the improvement of people’s living standards, now many families are raising some small pets, these small pets need a safe nest, pet cage has become a more important choice of people, each pet’s habits and living habits will choose to adapt to the cage.

...

soft black iron wire 【soft black iron wire】

Read Moresoft black iron wire

...

soft black iron wire 【soft black iron wire】

Read Moresoft black iron wire

...

soft black iron wire 【soft black iron wire】

Read Moresoft black iron wire

...

soft black iron wire 【soft black iron wire】

Read More

soft black iron wire

Post time: 29-08-22...

soft black iron wire 【soft black iron wire】

Read Moresoft black iron wire

...

soft black iron wire 【soft black iron wire】

Read Moresoft black iron wire

...

soft black iron wire 【soft black iron wire】

Read More

Popular articles

And high quality data and production cost and production conditions are bound, so some welding screen manufacturers did not meet the requirements of this aspect, natural in this case there is no way to improve product strength. In addition to data, and produce process, even if again good data, but the factory did not meet the requirements of production process in welding, also can form the product under the high pressure welding, so it is also a kind of strength on the decline, process conditions of different manufacturers also have very big difference, so it formed a shopping mall on the above products are differences of strength.

- 5, according to the thickness of the wire diameter to adjust zinc dipping time

Because of the large size of the barbed rope, the rope factory is used to packing. If you do not pack, then a load of blade rope can not hold many pieces, but also relatively occupy space and easy to be lost in the process of transportation.

Customers in the order of wire mesh will often shop around, most customers are in comparison with manufacturers to give the product price, the company tells you, do not blindly compare the price. To standards, production technology, manufacturers and other factors lead to different prices.

Post time: 24-10-22

Latest articles

-

-

Hard black galvanized iron wire is made of low carbon steel wire directly drawn by drawing machine. The primary characteristics of hard black galvanized iron wire are high hardness and bright appearance. Primary use for welding hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawn. The primary feature of soft black galvanized iron wire is good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving process, electric welding mesh, welding process products.

-

In general, the organic matter contained in the galvanized wire can make the plating speed significantly reduced. Although the chemical formulation is conducive to high deposition rate, but the organic matter with the coating thickness can not meet the requirements, so activated carbon can be used to treat the tank liquid. Zinc is a silver-white metal, brittle at room temperature, soluble in acid can also be soluble in alkali, known as amphoteric metal.

-

Black iron wire application in the process, the main is through the hot metal billet rolling into six point five mm wire rod, and then put it in the drawing into a line of different diameter, the plant and then gradually narrow drawing plate aperture, cooling and annealing, plating process, such as making a variety of different specifications of the wire, the wire compared with ordinary black iron wire, will be more softer, Softness is also very uniform, color is also consistent, widely used in the construction industry, mining, chemical industry, welding mesh, welding coat hanger, reprocessing industry and so on.

-

-

2.0*2.0mm 12 meters per kilogram

Links

Understanding 2% FT Ceiling Grid Tee Systems

The Role of Manufacturers

3. Installing Hangers Depending on the type of hanger used, it will be positioned to maintain a specified height, generally aligned with the overall ceiling design.

3. Regulations Some building codes require specific access panel sizes for safety and accessibility. Always check with local building regulations before making a purchase.

1. Planning the Layout Before installation, it is essential to plan the layout of the ceiling grid, including measurements and placement of fixtures.

- - Attach the hinges to one side of the panel using screws. Make sure they are secured tightly and that the hinges are flush with the edge of the panel. Position the opposite side of the hinges along the edge of the opening in the ceiling.

1. Convenience Maintenance tasks often require quick access to ceilings. Spring loaded access panels minimize disruption, allowing maintenance personnel to reach necessary utilities efficiently and without extensive time spent on setup.

High quality Mineral Fiber Ceiling Tiles

Metal grid ceilings are appreciated for their versatility and functionality. Typically made from materials like aluminum or galvanized steel, these ceilings can be designed to accommodate various lighting systems, HVAC elements, and acoustic panels, enhancing the overall ambiance and utility of a space. Clients in sectors ranging from commercial office spaces to educational institutions are increasingly opting for metal grid ceilings due to their robustness and modern look.

Benefits of Rondo Ceiling Access Panels

In the realm of modern interior design, ceilings play a crucial role in determining the overall aesthetic and functionality of a space. Among the various options available, PVC (Polyvinyl Chloride) grid false ceilings are gaining significant popularity due to their versatility, durability, and aesthetic appeal. This article explores the characteristics, benefits, and applications of PVC grid false ceilings, shedding light on why they are an excellent choice for both residential and commercial spaces.

Once you've chosen the location, measure the dimensions of the access panel. Using these measurements, mark the outline on the ceiling with a pencil. Use a level to ensure your markings are straight. Make sure to leave enough space around the edges for proper installation and fitting.

4. Custom Sizes Available in various sizes, spring loaded panels can be customized to fit specific needs. Whether you require small access points for electrical conduits or larger openings for ductwork, there are options available to meet diverse requirements.

Understanding the T Grid Suspension System

The size of an access panel directly affects its usability. An appropriately sized panel allows maintenance personnel to reach electrical, plumbing, and HVAC systems without causing extensive damage to the surrounding structures. If the panel is too small, technicians may struggle to access the equipment, leading to potential damage and costly repairs. Conversely, if the panel is excessively large, it can compromise the integrity of the ceiling and create aesthetic issues.

What is a Plasterboard Ceiling Hatch?

Understanding Access Panel Ceiling Size A Comprehensive Guide

The Importance of T-Grid Ceiling Suppliers in Modern Construction

T-grid ceilings play a crucial role in modern construction and design, providing functional benefits and creating visually appealing environments. The choice of supplier is critical to the successful implementation of these ceilings. By considering factors such as product quality, variety, expertise, and reputation, contractors and designers can ensure they select a reliable partner for their T-grid ceiling needs. As the industry continues to evolve, T-grid ceilings are likely to remain a staple in commercial interiors, enhancing the way we experience space.

1. Compliance with Building Codes Many jurisdictions have strict building codes that require the installation of fire rated doors in certain areas. Non-compliance can lead to significant penalties, including fines and even mandating costly retrofits.

3. Corner Brackets Designed specifically for securing T-bars at corners where two walls meet, these brackets ensure that the grid remains stable and aligned.

ceiling t bar bracket

The use of plastic grids is also increasingly popular in industrial environments. They can be installed in factories and warehouses where exposure to moisture and corrosive substances is common. The durability and resistance properties of plastic ensure that these grids can withstand harsh conditions while providing a reliable ceiling system.

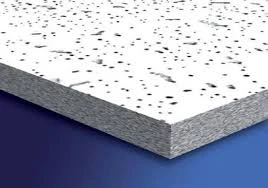

Mineral fiber ceiling boards, a popular choice in modern construction and interior design, have gained significant traction due to their aesthetic appeal and functional benefits. These ceiling tiles are primarily made from a combination of inorganic mineral fibers, often including materials such as fiberglass and mineral wool, which provide a unique blend of sound absorption, thermal insulation, and fire resistance.

1. Accessibility One of the primary functions of a ceiling hatch is to provide easy access to vital systems installed above ceilings. Whether it’s for HVAC maintenance, electrical repairs, or plumbing inspections, having quick access can save time and labor costs.

- Acoustic Access Panels These panels are designed to minimize sound transmission, making them ideal for commercial buildings where noise control is a priority.

One of the primary functions of hanger wire is to support the weight of the ceiling grid and any materials that may be added, such as acoustical tiles, light fixtures, and HVAC systems. The rigidity and tensile strength of the hanger wire are crucial for maintaining the ceiling’s integrity and alignment. If the wire is not sufficiently strong or correctly installed, it could lead to sagging, misalignment, or even structural failure of the ceiling system, posing safety risks in occupied spaces.

What are Mineral Fiber Acoustic Ceilings?

3. Aesthetic Versatility FRP ceiling grids are available in various designs, colors, and finishes, providing ample options for customization. Whether aiming for a modern look or something more traditional, designers can find an FRP grid that complements the overall theme of the space. The ability to mix and match different styles enhances the creative possibilities for interior spaces.

frp ceiling grid

3. Customization Options Not all buildings are the same. A good supplier should offer customization options to tailor the trap doors to your design and functional needs.

Exploring Ceiling Hatches A Guide to Understanding and Selecting the Right Option

The Benefits of Ceiling Mineral Fiber

In modern construction and building design, the functionality and aesthetic qualities of a structure are paramount. Among the essential components that facilitate the maintenance and operation of building systems are ceiling access doors and panels. These often-overlooked features play a crucial role in ensuring that a facility remains functional and accessible while maintaining its visual appeal.

While installing flush mount ceiling access panels can be straightforward, several factors must be considered to ensure proper fit and functionality. It’s essential to assess the structural elements above the ceiling, such as beams and ductwork, to choose an appropriate location for the panel. Additionally, quality materials should be used to ensure durability and performance over time.

Professional installation may be advisable to avoid common pitfalls, such as misalignment or improper sealing, which can lead to visibility issues or compromise the acoustics of the space.

Functional Benefits

As sustainability becomes increasingly important in construction and design, many manufacturers now offer eco-friendly T-bar ceiling panels made from recycled materials. These products not only contribute to reducing waste but can also help builders achieve LEED certification, which recognizes environmentally responsible building practices.

Design and Specifications

The advantages of integrating ceiling access panels into drywall systems are multifaceted

Gypsum ceiling access panels are essential components in modern architecture and interior design, particularly in commercial and residential buildings. As buildings become more complex, the need for convenient access to concealed spaces for maintenance, inspection, and installation has grown, making access panels a critical addition to ceiling designs.

Installation Process

Mineral fiber planks are ceiling tiles crafted from a blend of mineral materials, including gypsum, perlite, and fiberglass. These materials are combined and formed into planks or tiles. The result is a lightweight, durable, and highly effective ceiling solution that is often used in suspended ceiling systems. Available in various sizes, thicknesses, and finishes, mineral fiber planks can cater to diverse design needs and preferences.

- Commercial Buildings In office spaces, gypsum tiles can be used for suspended ceilings or as wall finishes to improve acoustics and aesthetics. They contribute to a professional atmosphere while maintaining comfort for employees and clients.

5. Aesthetic Integration A ceiling hatch should blend well with the surrounding architecture. Choosing a size that complements the design of your space is crucial for maintaining a cohesive look.

1. Mineral Wool This is one of the primary constituents of mineral fiber tiles. Mineral wool, also known as rock wool or stone wool, is produced from the melting of basalt rock and recycled slag. Once the fibers are spun and formed into mats, they are processed into tile form. Mineral wool is particularly valued for its ability to provide sound insulation and thermal resistance.

1. Planning and Measuring Accurate measurements are crucial. Begin by marking the layout on the walls and ceiling where the grid will be installed.