what size screws for drywall ceiling

Latest articles

what size screws for drywall ceilingAfter electric galvanizing hot galvanizing. Electroplated copper and other common applications of screen consumption. The weaving of the binding of the building steel wire mesh has the first braided after plating, plating after weaving and other methods, after the disposal of the wire mesh or wire mesh has good corrosion, oxidation resistance characteristics, can be used in the construction, petroleum, chemical, aquaculture, garden protection, food processing and other industries of reinforcement, protection and insulation.

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read Morewhat size screws for drywall ceiling

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read More5. It prevents your dog’s fear from causing chaos or other problems.

what size screws for drywall ceiling...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read Morewhat size screws for drywall ceiling

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read Morewhat size screws for drywall ceiling

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read Morewhat size screws for drywall ceiling

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read MoreTwo, cold galvanized wire production process of galvanized. Galvanizing is the core process in the production of cold galvanized wire, mainly by soaking the steel wire in a molten zinc solution to form a zinc layer on its surface.

what size screws for drywall ceiling...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read More

what size screws for drywall ceilingRemoval of surface-active substances by activated carbon matting. Or make the bubble unstable according to overworry, these are all reasonable countermeasures; Other strategies should also be used to minimize the amount of surfactant taken in. The introduction of organic matter can make the electroplating process speed drop sharply. Galvanized iron wire blackening can be effectively prevented, such as: the work site to keep dry, reduce and do not use chemicals, operators with clean gloves and so on. In addition, hot dipping zinc factory can be required, after dipping zinc must be passivation treatment, passivation treatment of zinc has a better anti-discoloration effect, can effectively prolong the discoloration time, the combination of the two, discoloration should be able to solve.

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read Morewhat size screws for drywall ceiling

...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read MoreOne is to do a good job of galvanized wire packaging, avoid bump, to ensure the integrity of the zinc layer;

what size screws for drywall ceiling...

what size screws for drywall ceiling 【what size screws for drywall ceiling】

Read More

Popular articles

Post time: 28-01-23Galvanized iron wire can be divided into hot-dip galvanized iron wire and cold galvanized iron wire according to different processing methods. Galvanized iron wire is more prominent in its corrosion resistance. Galvanized iron wire has good toughness and elasticity, the amount of zinc can reach 300 g/square meter, with thick galvanized layer, strong corrosion resistance and other characteristics. Galvanized iron wire products are widely used in construction, handicrafts, wire mesh preparation, the production of galvanized hook mesh, wall mesh, highway guardrail, product packaging and daily civilian and other fields.

Post time: 21-04-23

Post time: 08-09-22

Latest articles

-

Some customers do not understand the scope of application of different styles of barbed rope, there is a great difference.

-

Post time: 04-11-22 -

Select cut silk first to ensure that the raw material of the silk is exactly the raw material you need, the raw material will be used well. Choose high straightness, so that the length of the truncation will be the same, will not show a lot of length difference, the length of the truncated wire is a very important element to choose the truncated wire.

-

-

Post time: 15-09-22 -

Post time: 03-04-23

Links

- Conclusion

- Many people choose to mix and match cotton and polyester sheets to get the best of both worlds. For example, you can use a cotton fitted sheet for comfort and breathability, and a polyester flat sheet for wrinkle resistance and durability. Ultimately, the most important thing is to choose sheets that feel comfortable to you and suit your lifestyle.

- In terms of durability, bamboo sheets surpass many other fabrics

- * Hypoallergenic options For those with allergies or sensitive skin, there is a growing selection of hypoallergenic duvet covers made from materials like wool or microfiber.

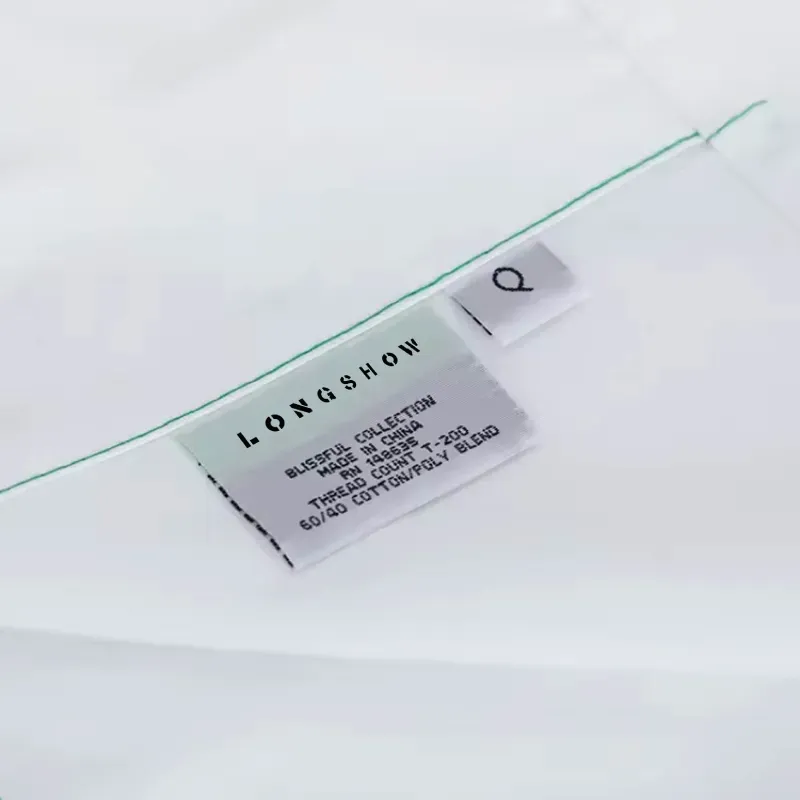

Choose 200 thread count and above - anything less will wear badly, rip and develop holes! Be wary of really high thread counts over 800 which can produce very stiff sheets and duvet covers that are not very comfortable to sleep on and are really hard to iron! We picked 600 thread count for our Egyptian cotton bed linen.

- Benefits of Using a Very Light Duvet Insert

From £40.00Shop Now

- The standard bed sizes in the United States are twin, full, queen, king, and California king. Each size has its own unique dimensions, and it's essential to choose a bed sheet size that is compatible with your bed to avoid wrinkles, sagging, or excess fabric.

- In conclusion, a tan bedspread is a versatile and stylish choice for any bedroom. Its neutral color palette, cozy vibe, and practicality make it a popular option for those looking to create a welcoming and stylish space. Whether you prefer a classic and timeless look or something more modern and eclectic, a tan bedspread can help you achieve the bedroom of your dreams.

- Size: Both sheets come tailored for various mattress dimensions. Fitted sheets, with their elastic edges, are designed to match the exact size of the mattress, be it twin, queen, or king. On the other hand, flat sheets often come in slightly larger dimensions, allowing for the extra fabric to be tucked under the mattress or draped over the sides, adding to the bed's layered look.

● It is simple and quick to clean.

hospital bed cotton sheets. Hospital bed cotton sheets are typically made from high-quality, pre-washed cotton that has been treated with an antimicrobial agent to inhibit the growth of bacteria and other microorganisms. This helps to reduce the risk of infection transmission and maintain a clean and healthy environment for patients and staff alike.

hospital bed cotton sheets. Hospital bed cotton sheets are typically made from high-quality, pre-washed cotton that has been treated with an antimicrobial agent to inhibit the growth of bacteria and other microorganisms. This helps to reduce the risk of infection transmission and maintain a clean and healthy environment for patients and staff alike.Weave affects the way a sheet looks, feels and its overall durability. Plain weaves, such as Percale sheets, have an equal number of vertical and horizontal yarns woven together. Plain weave sheets are known for their longevity and crisp feel. Sateen sheet weaves are woven with more vertical than horizontal yarns. The higher number of vertical threads gives the sheet ultra softness. Twill weaves are yarns that are woven two over and one under to create a diagonal line on one side of the fabric. These linens tend to be soft and tend to hold their shape well. Jacquard and damask are weaves that have intricate patterns.

What is a Duvet Cover, and what is it used for?

Tencel sheets are made from sustainable wood pulp and are known for their silky smooth texture and moisture-wicking properties.

duvet insert protector. By absorbing the brunt of daily wear and tear, it prevents the fill from shifting or clumping, keeping your duvet fluffy and evenly distributed. It also guards against rips and tears, which could otherwise compromise the insulation properties of the insert.

duvet insert protector. By absorbing the brunt of daily wear and tear, it prevents the fill from shifting or clumping, keeping your duvet fluffy and evenly distributed. It also guards against rips and tears, which could otherwise compromise the insulation properties of the insert. waffle knit robe long. It can be worn as a post-bath wrap, a layer of warmth on chilly nights, or even as a stylish addition to a casual outfit. Available in a spectrum of colors, from classic neutrals to bold hues, these robes can reflect one's personal style and mood.

waffle knit robe long. It can be worn as a post-bath wrap, a layer of warmth on chilly nights, or even as a stylish addition to a casual outfit. Available in a spectrum of colors, from classic neutrals to bold hues, these robes can reflect one's personal style and mood.To help simplify your search, we have compiled the ultimate guide to bed sheets. We have tested tons of sheets here at Sleepopolis (check out our favorites on ourbest sheetspage!) and we are bringing that hands-on knowledge to you.

Percale Sheets

When choosing sheets based on the thread count, keep in mind there are a few materials that can have a smaller number of threads and still be very durable. For example, linen sheets generally have a low thread count, so a good quality linen sheet can have a thread count of 120, but a cotton sheet would need upwards of 500 to be good quality.

Satin:Satin is an extremely similar weave to sateen — in fact, it’s basically the same thing. Satin also uses a three or four over, one under weave. However, thedifferencelies in the materials used to create the weave. Satin is made exclusively with filament fibers, while sateen is made with staple fibers.