Understanding Standard Welded Wire Mesh Sizes

Welded wire mesh is a versatile and widely used material in construction, agriculture, and various industries. It is made from intersecting wires that are welded together at their junctions, forming a grid-like structure. This characteristic lends it strength and durability, making it suitable for a range of applications. Understanding standard welded wire mesh sizes is crucial for selecting the right type for your project.

Common Sizes and Dimensions

Welded wire mesh comes in various sizes and configurations, which can be tailored to meet specific needs. The most common mesh openings include square or rectangular shapes, the sizes of which are typically measured by the spacing between the wires. Standard wire diameters generally range from 14 to 4 gauge, with 14 gauge being thinner and 4 gauge being much thicker.

For example, a commonly used dimension is a mesh with 1-inch square openings made from 16-gauge wire. This configuration is often used for garden fencing, animal enclosures, and light construction. Other popular sizes include 2-inch squares, frequently employed in heavier applications such as commercial construction and safety barriers.

Size options expand further when considering the thickness of the wire used. Thicker wires provide increased strength and durability, making them suitable for high-stress environments. The choice of wire diameter primarily depends on the application requirements. For instance, a 6-inch square mesh using 10-gauge wire might be ideal for heavy-duty applications while offering excellent load-bearing capabilities.

Importance of Using Standard Sizes

Using standard sizes for welded wire mesh has several advantages. Firstly, it simplifies the purchasing process as these dimensions are readily available from suppliers. This availability reduces lead times and can decrease costs, particularly for bulk purchases.

Secondly, standard sizes ensure compatibility with other construction materials and methods

. For example, if you are building a fence or reinforcement for concrete, matching your mesh size with the spacing of bars or other materials proves crucial for structural integrity.standard welded wire mesh sizes

Moreover, the predictability of standard sizes allows for better project planning. Contractors can easily calculate the amount of material needed, minimizing waste and ensuring adequate supplies always.

Selecting the Right Welded Wire Mesh

When selecting welded wire mesh, you should consider several factors, including the intended application, the environmental conditions, and local building codes. For agricultural purposes, such as sheep fencing, opting for a smaller mesh size (e.g., 2-inch by 4-inch openings) can help prevent smaller animals from escape or intrusions, while providing the strength necessary to withstand environmental pressures.

In industrial environments where heavy machinery may be present, a thicker wire and larger mesh size may be needed to ensure safety and durability. For this reason, evaluating the environment in which the wire mesh will be used is essential for safe and effective application.

Finishing Options

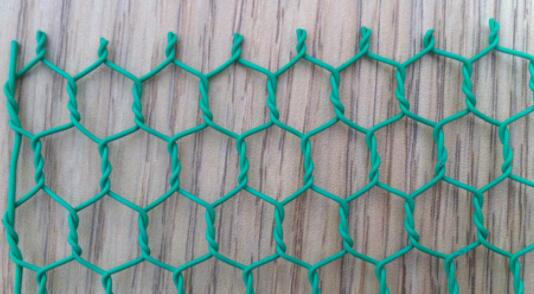

In addition to standard sizes, welded wire mesh can also come with a variety of finishing options. Galvanized wire mesh, for example, is coated with zinc to prevent rust and corrosion, making it suitable for outdoor use. PVC coated options provide an additional layer of protection while enhancing aesthetic appeal for residential settings.

Conclusion

In summary, understanding standard welded wire mesh sizes is vital for anyone involved in construction or agriculture. The right size not only ensures the project's success but also improves efficiency and cost-effectiveness. Always consider the application requirements, environmental conditions, and compatibility with other materials when selecting welded wire mesh. By doing so, you can make informed decisions that meet your project's needs effectively.