Understanding the 30% 20 Mesh Screen Applications and Importance

In industries ranging from agriculture to material sciences, the importance of sieving and screening processes cannot be overstated. At the heart of these processes often lies the mesh screen, a vital tool designed to filter materials based on their size. One widely discussed type is the 30% 20 mesh screen, which plays a critical role in various applications. This article delves into the significance, specifications, and applications of a 30% 20 mesh screen.

What is a Mesh Screen?

A mesh screen is essentially a grid-like structure made from a metal or polymer material, characterized by its mesh openings defined in terms of the number of openings per linear inch. The designation 20 mesh indicates that there are 20 openings in a linear inch of the screen. Consequently, the size of the openings is approximately 0.033 inches or 0.841 millimeters. Conversely, a 30% designation regarding the mesh implies that around 30% of the mesh area is open space, allowing materials to pass through while retaining others based on their size.

Specifications of a 30% 20 Mesh Screen

The characteristics of a 30% 20 mesh screen highlight its utility in various operations. The term 30% emphasizes that this mesh allows a significant portion of material to pass while retaining a substantial fraction. This can be particularly useful when one needs to separate fine particles from coarse materials efficiently. The construction material of the screen can vary—common materials include stainless steel, nylon, or woven wire—each offering different benefits in terms of durability and resistance to corrosion or chemical reactions.

The operational parameters of a 30% 20 mesh screen can greatly influence its performance. These include the input material type, moisture levels, and the specific application at hand. Understanding these parameters is crucial for operators to achieve optimal separation efficiency.

Applications of the 30% 20 Mesh Screen

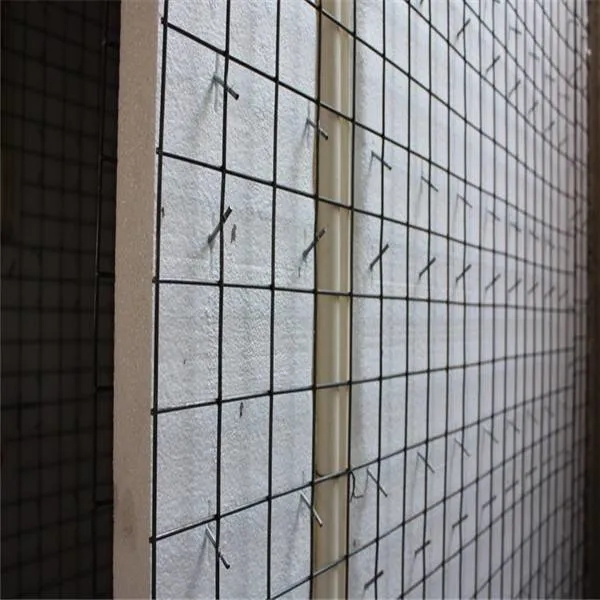

30 mesh screen

1. Agriculture In the agricultural sector, a 30% 20 mesh screen is often employed for sifting seeds, fertilizers, and soil amendments. The screen helps in removing larger debris and rocks, thereby facilitating a cleaner planting process. Additionally, this mesh can be used in processing certain food products, allowing for the separation of flour from larger particles during milling.

2. Construction and Material Recycling In construction, this screen is instrumental in sorting aggregates used in concrete and asphalt production. It plays a pivotal role in recycling materials by filtering out contaminants and preparing reclaimed materials for reuse in construction projects. The ability to handle a range of material sizes makes the 30% 20 mesh an excellent choice for diverse applications.

3. Mining and Mineral Processing In the mining industry, screens are essential for classifying materials and separating valuable minerals from waste rock. The 30% 20 mesh screen can effectively filter out smaller particles and retain larger, more valuable nuggets or ores. This process enhances efficiency in mineral extraction operations.

4. Chemical Industry In the chemical sector, the 30% 20 mesh screen is utilized to separate particles in various processes, such as the production of powders and granules. This mesh is also useful for quality control, ensuring that products meet the required specifications in terms of particle size distribution.

5. Waste Management In the realm of waste management, a 30% 20 mesh screen is employed in sorting and separating recyclable materials. By efficiently filtering out non-recyclables from recyclables, this mesh contributes to more effective recycling processes.

Conclusion

In conclusion, the 30% 20 mesh screen serves as a crucial component across numerous industries. Its ability to efficiently filter and separate materials based on particle size enhances productivity and quality in various processes. As industries continue to evolve and seek more efficient methods of production and processing, the role of mesh screens like the 30% 20 will undoubtedly remain indispensable. Understanding their properties and applications not only contributes to improved operational efficiency but also supports advancements in technology and sustainability across sectors.