Understanding 1% and 4% Drywall Screws Choosing the Right Fastener for Your Project

When it comes to drywall installation, selecting the appropriate screws can significantly affect the durability and finish of your project. Among the various options available, 1% drywall screws and 4% drywall screws often come up in discussions about fasteners. Though these terms may not be widely recognized, they can refer to the grade or type of drywall screw you choose in relation to the specific application. In this article, we will explore the characteristics, advantages, and best applications for 1% and 4% drywall screws to help you make an informed decision for your next project.

What Are Drywall Screws?

Before diving into the specifics, it’s essential to understand what drywall screws are. Typically made from steel and often coated for corrosion resistance, drywall screws are specially designed for fastening gypsum board to wood or metal studs. They feature a sharp tip that allows for easy penetration and spaced threads that provide excellent holding power.

The Importance of Screw Selection

Selecting the right screw for your drywall installation can be the difference between a secure attachment and a compromised structure. Drywall screws come in two main types coarse-thread and fine-thread. Coarse-thread screws are ideal for wooden studs, while fine-thread screws are preferred for metal studs. The distinction in thread pattern affects the screw's grip and stability, which is particularly important as drywall serves not just as a separator but also as a foundation for finishes such as paint or wallpaper.

Analysis of 1% and 4% Screws

While 1% drywall screws and 4% drywall screws do not correspond to standard industry measurements or specifications, we can analyze them conceptually. These percentages can be associated with the density or thickness of the screw coating, the material strength, or even the level of corrosion resistance.

1. 1% Drywall Screws If we consider 1% drywall screws as those with lower density or thinner coating, they may be less robust. Such screws could be suitable for light-duty installations or projects that do not require high strength, such as securing lightweight panels or in areas with minimal stress. However, their performance could be limited due to potential rusting or failure under pressure.

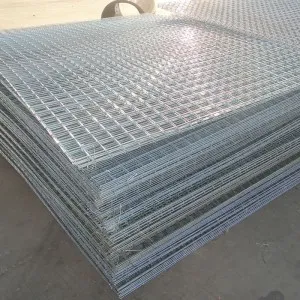

1 1 4 in drywall screws

2. 4% Drywall Screws In contrast, if we view 4% drywall screws as being of higher quality or thicker coating for enhanced corrosion resistance, these would be more suitable for heavy-duty applications. These screws would perform better in areas that experience significant temperature changes or moisture, such as kitchens or bathrooms. Their sturdiness makes them ideal for securing panels in environments where a strong hold is paramount.

Advantages of High-Quality Screws

Choosing a higher-quality screw, such as the conceptual 4% screw, offers several advantages

- Strength Stronger screws provide better holding power, reducing the likelihood of drywall sagging or failing over time. - Corrosion Resistance A thicker coating protects against rust and degradation, especially in humid environments. - Reduced Strip-Out High-quality screws are less likely to strip out when being installed, ensuring a secure fit in the material.

Best Practices for Installation

Regardless of the type of drywall screw you choose, following best practices during installation is vital for ensuring a long-lasting finish

1. Use a Screw Gun A screw gun allows for consistent depth control, preventing the screw from over-penetrating and damaging the drywall. 2. Space Screws Properly Adhere to local building codes for screw spacing, typically 12-16 inches apart along the edges and in the field of the drywall. 3. Pre-Drill if Necessary In some scenarios, especially with hardwood or when using thicker screws, pre-drilling can help avoid splitting the material.

Conclusion

In summary, while 1% drywall screws and 4% drywall screws may not be standardized terms in the industry, understanding their conceptual differences can help in selecting the right fasteners for your drywall installation. The choice between a lightweight option and a more robust, corrosion-resistant screw can impact the longevity and durability of your project. Always consider the specific needs of your installation, and don’t hesitate to invest in quality screws that will contribute to a securely finished product. By adhering to best practices and selecting the right materials, you can ensure a professional-quality finish that will stand the test of time.