Understanding Welded Wire Fabric Sizes A Comprehensive Guide

Welded wire fabric is a versatile and widely used material in construction and engineering applications. This grid-like structure, typically made from low carbon steel wire, is utilized in various situations, including reinforcing concrete, creating fences, and serving as support for various structures. One critical aspect that many engineers, contractors, and DIY enthusiasts must consider is the size of welded wire fabric. In this article, we will delve into the different sizes available, their applications, and why choosing the right size is essential for a successful project.

What is Welded Wire Fabric?

Welded wire fabric (WWF), also known as welded wire mesh, consists of a series of longitudinal and transverse wires that are welded at intersections, forming a sturdy grid. This material predominately comes in flat sheets or rolls and is manufactured in various sizes, gauges, and spacings, allowing it to cater to a wide array of needs. The most common uses include providing support for concrete pours, constructing safety barriers, and making cages for animal enclosures.

Standard Sizes and Dimensions

Welded wire fabric is available in a variety of standard sizes, often categorized by the spacing of the wires and the diameter of the wire itself. The wire diameter is usually expressed in gauges, with a smaller gauge indicating a thicker wire. Common dimensions for welded wire fabric include

- Wire Sizes The wire diameter can range from 10 gauge (about 0.102 inches) to 18 gauge (about 0.0475 inches). A commonly used dimension for construction purposes includes 6-gauge wire for heavily loaded applications, while thinner wires like 16-gauge may be used for lightweight needs. - Grid Spacing Welded wire fabric typically comes in grid spacings of 2 inches, 4 inches, or even 6 inches, depending on the application. The spacing refers to the distance between the bars, which directly affects the strength and support provided by the mesh. For instance, a 6-inch spacing might be suitable for slab reinforcement in a residential setting, while tighter spacing, like 2 inches, may be preferred in heavy-duty industrial applications.

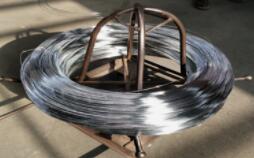

welded wire fabric sizes

- Sheet Sizes Standard sheet sizes for welded wire fabric can vary widely, but common dimensions are 5 feet by 10 feet, 6 feet by 12 feet, or customized sizes to fit specific project needs. Rolls of welded wire fabric can also be found in dimensions of 48 inches wide by lengths of up to 150 feet.

Applications of Different Sizes

Different sizes of welded wire fabric are suited for various applications. For example, thicker wire with closer grid spacing is ideal for high-load applications, such as industrial floors, highways, or airport runways, where the forces acting on the concrete are significant. Conversely, lighter wire with larger spacing might be more appropriate for residential construction projects, such as foundations and sidewalks, where the loads are considerably lower.

Additionally, the choice of size can affect the cost-effectiveness of a project. Using larger sheets or rolls can reduce labor time and material waste, while selecting the appropriate wire gauge can ensure that the structural integrity of the project is maintained without unnecessary expenditure on overly robust materials.

Importance of Selecting the Right Size

Choosing the appropriate size of welded wire fabric is paramount for several reasons. First and foremost, it directly impacts the structural integrity of the construction. The right dimension can ensure that the fabric provides sufficient support and reinforcement, thus preventing cracks and failures. Moreover, using improperly sized fabric can lead to increased labor costs and project delays, as adjustments would be necessary to meet engineering standards.

In summary, understanding welded wire fabric sizes is crucial for anyone involved in construction or engineering. By carefully considering wire gauges, grid spacing, and sheet sizes, individuals can select the most suitable material for their projects, ensuring structural safety, effectiveness, and cost-efficiency. Whether you are a seasoned professional or a novice, taking the time to understand these dimensions will help ensure the success of your construction endeavors.