Welding Steel Mesh Techniques and Applications

Welding steel mesh is a crucial technique in various industries that require strength, durability, and structural integrity. Steel mesh, often made from high-tensile wire, serves as an essential framework that enhances the stability of concrete structures, provides reinforcement, and creates secure enclosures. The process of welding steel mesh involves several methods and practices that ensure the end product meets specific safety and design standards.

One of the primary methods used in welding steel mesh is resistance welding. This technique involves the application of electrical current and pressure to weld overlapping steel wires together. The resistance produced by the wire generates heat, which melts the materials at the contact point, resulting in a strong bond between the wires. This method is preferred for its efficiency, speed, and ability to produce consistent, high-quality welds. It is particularly suitable for manufacturing large quantities of mesh panels quickly, making it an ideal choice for construction projects.

Another prevalent method is the arc welding technique, which utilizes an electric arc to melt the base metal and create a joint. This method can be used for thicker steel sections that might not be suitable for resistance welding. Arc welding can be performed in various positions, offering versatility in applications. However, it requires skilled operators to ensure proper settings and techniques are applied, which can directly affect the strength and quality of the welded mesh.

Welded steel mesh is widely used in construction, particularly in flooring and reinforcing concrete. When embedded within concrete slabs or walls, steel mesh significantly enhances the tensile strength of the structure. This reinforcement helps to prevent cracking and provides additional support, ultimately leading to safer and more durable buildings. The mesh is also employed in precast concrete products, such as panels and beams, where uniformity and strength are paramount.

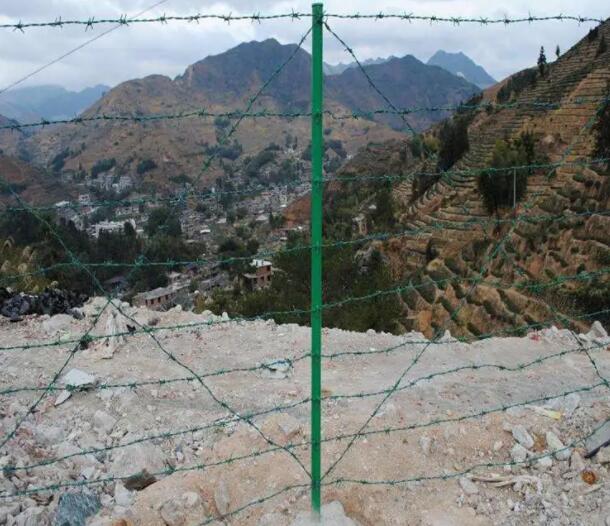

welding steel mesh

In addition to construction, welded steel mesh has diverse applications in other industries. For instance, it is commonly used in the manufacturing of fencing systems for security purposes. The robust nature of steel mesh makes it an excellent deterrent against intrusions, providing peace of mind for residential, commercial, and industrial properties. Additionally, it plays a critical role in agriculture, where it is used for livestock enclosures and crop protection.

Moreover, the automotive and aerospace industries utilize welded steel mesh in various components, including heat shields and structural frameworks, where weight reduction without compromising strength is essential. The lightweight nature of welded steel mesh allows for enhanced fuel efficiency in vehicles while maintaining structural integrity.

The advantages of welding steel mesh extend beyond its applications; it also contributes to sustainability in construction. Many steel products are made from recycled materials, which reduces the overall carbon footprint. Furthermore, welded steel mesh can be designed to meet specific load-bearing requirements, minimizing the need for excess materials and reducing waste.

Despite its numerous benefits, challenges exist in the welding process of steel mesh. Operators must ensure proper alignment and handling of the mesh to prevent distortions or misalignments during welding. Additionally, the quality of the base materials plays a crucial role in determining the overall performance of the welded mesh.

In conclusion, welding steel mesh is an essential process that forms the backbone of various industries. Its versatility, strength, and durability make it indispensable in construction, agriculture, automotive, and beyond. As technology advances, innovations in welding techniques and materials will continue to improve the efficiency and effectiveness of steel mesh applications, paving the way for even more robust and sustainable solutions in the future.