Understanding 1 8 Wire Screen Applications and Importance in Various Industries

In the vast landscape of industrial materials, wire screens hold a pivotal position in various applications. Among them, the 1 8 wire screen has emerged as a distinctive type, characterized by its intricately woven fine mesh structure that makes it ideal for a plethora of uses. This article delves into the specifics of 1 8 wire screen, its applications, and its significance across various sectors.

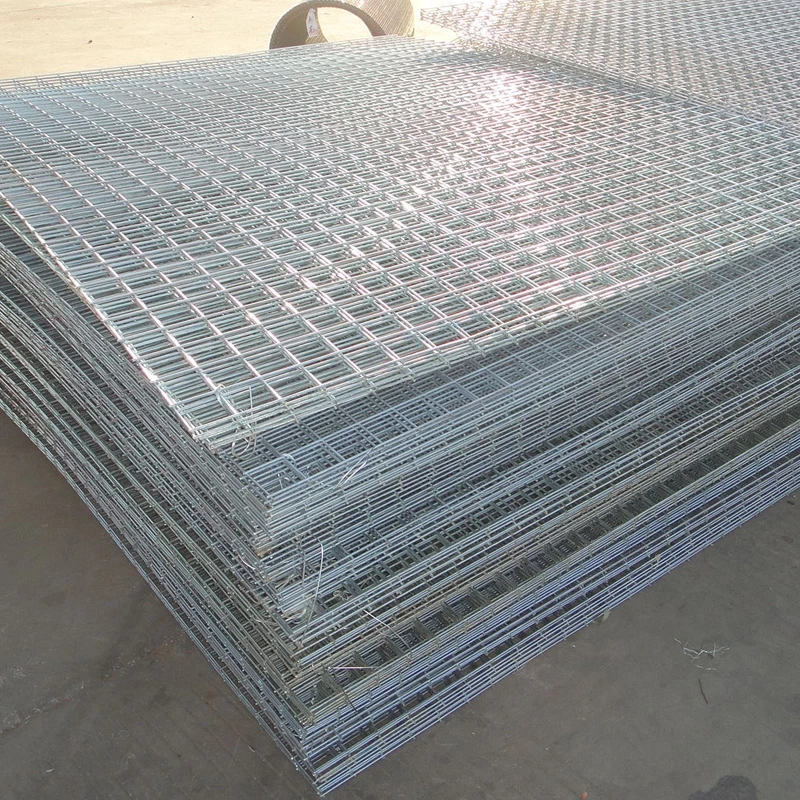

What is 1 8 Wire Screen?

The term 1 8 wire screen refers to a specific gauge and pattern of wire mesh that is produced using high-quality stainless steel or other alloys. The 1% might denote the wire diameter, while 208 could signify the number of openings per linear inch. The unique combination of these characteristics imparts specific physical and chemical properties, making this wire screen exceedingly versatile.

The specification also implies that this wire screen possesses a low percentage of a particular alloy, potentially related to its corrosion resistance and mechanical strength. The woven structure results in a durable yet flexible material that can be crafted into sheets or rolls, depending on the intended use.

Applications of 1 8 Wire Screen

1. Filtration One of the primary applications of 1 8 wire screen is in filtration systems. Its fine mesh structure allows for efficient separation of particles, making it vital in industries such as food processing, pharmaceuticals, and water treatment. The mesh can trap impurities while allowing desired fluids to pass through, thereby enhancing product quality and safety.

2. Architecture and Design In the realm of architecture, 1 8 wire screens are used for aesthetic and functional purposes. Designers use this wire mesh to create visually appealing facades, partitions, and railings that also serve as protective barriers. The ability to customize the weave and openness of the mesh means that it can complement various architectural styles while providing structural integrity.

1 8 wire screen

3. Mining and Aggregate Industry The mining sector extensively employs wire screens, especially for sifting and sorting materials. The 1 8 wire screens can be integrated into vibrating screens to optimally separate different grades of aggregates and minerals, enhancing the overall efficiency of mining operations.

4. Agriculture In agriculture, this type of wire screen can be employed for constructing chicken coops, greenhouses, and protective enclosures. Its durability ensures that it withstands harsh environmental conditions while providing safety for plants and livestock.

5. Industrial Machinery Various machines depend on wire screens for operational efficiency. The 1 8 wire screen can act as a sieve or filter in machines that require the separation of solids from liquids or finer particles from coarser ones. This application is crucial in manufacturing processes where precision is paramount.

Importance of 1 8 Wire Screen

The significance of the 1 8 wire screen transcends its utility in diverse applications. First and foremost, its durability ensures longevity, thereby reducing the need for frequent replacements and minimizing overall costs. Furthermore, its resistance to corrosion and rust makes it suitable for use in challenging environments, ensuring consistent performance over time.

Moreover, the adaptability of the wire screen design allows industries to customize their solutions based on specific requirements, promoting innovation and efficiency in operations. This versatility opens up opportunities for new applications and improvements in existing processes.

Conclusion

In summary, the 1 8 wire screen represents an essential component across a multitude of sectors. Whether it is for filtration, architectural design, mining, agriculture, or industrial machinery, its unique properties make it invaluable. As industries continue to evolve and adapt to new challenges, the role of wire screens, particularly the 1 8 type, will undoubtedly expand, driving progress and innovation. Understanding its applications and importance is crucial for professionals across these industries, ensuring they leverage its benefits to enhance their operational efficacy.