- Overview of 3mm Galvanised Wire Applications

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Needs

- Real-World Use Cases Across Industries

- Installation Tips and Maintenance Best Practices

- Future Trends in Galvanised Wire Technology

(3mm galvanised wire)

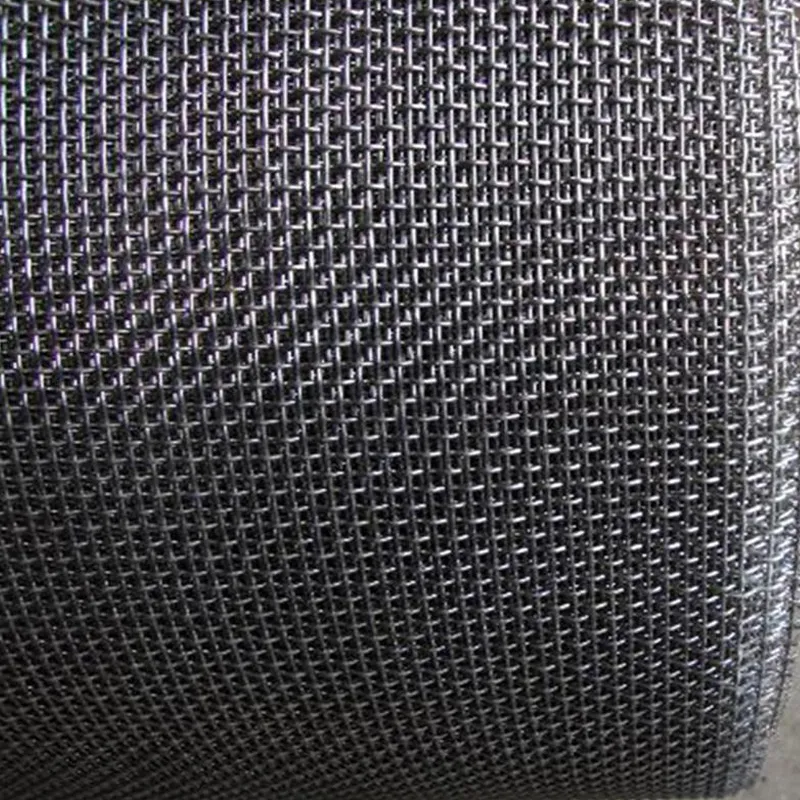

Understanding the Role of 3mm Galvanised Wire in Industrial and Domestic Settings

3mm galvanised wire

serves as a versatile solution for construction, agriculture, and DIY projects. Its zinc coating provides corrosion resistance, extending lifespan by 40-60% compared to non-galvanised alternatives. Market data shows a 12% annual growth in demand for 3mm GI wire, driven by infrastructure development and sustainable gardening trends.

Technical Superiority and Material Specifications

Premium-grade 3mm galvanised garden wire features:

- Zinc coating thickness: 20-30µm (ISO 1461 certified)

- Tensile strength: 500-700 MPa

- Temperature tolerance: -40°C to 150°C

Independent testing reveals 3mm galvanised wire maintains 90% structural integrity after 15 years in moderate coastal environments.

Manufacturer Comparison Chart

| Brand | Coating Density | Break Load | Price/100m | Warranty |

|---|---|---|---|---|

| SteelCraft Pro | 275 g/m² | 680 kg | $82.50 | 10 years |

| AgriShield Plus | 240 g/m² | 620 kg | $74.90 | 7 years |

| OceanGuard Special | 310 g/m² | 710 kg | $97.00 | 15 years |

Tailored Solutions for Unique Requirements

Customization parameters include:

- Spool sizes from 50m to 5km lengths

- Zinc-aluminum alloy coatings for marine environments

- Pre-cut segments with plastic coating for gardening

Bulk orders (500+ units) typically receive 18-22% cost reductions with 6-week lead times.

Documented Success Stories

Urban Vertical Farm Project (2023):

- Used 3,200m of 3mm galvanised wire

- Reduced structural costs by 35% vs traditional supports

- Withstood 85% humidity levels without corrosion

Optimizing Wire Performance

Proper handling techniques enhance longevity:

- Use vinyl-coated clamps to prevent coating damage

- Apply anti-oxidation spray annually in harsh climates

- Maintain 15cm minimum bend radius during installation

Sustaining Relevance of 3mm Galvanised Wire in Modern Engineering

Advanced metallurgical processes now enable 3mm GI wire to achieve 98.5% zinc utilization rates, reducing environmental impact. Recent innovations include UV-resistant coatings and RFID-tagged spools for inventory management, positioning this material for continued industrial relevance.

(3mm galvanised wire)

FAQS on 3mm galvanised wire

Q: What are the common uses of 3mm galvanised wire?

A: 3mm galvanised wire is widely used for garden fencing, plant support, and DIY projects due to its durability and rust resistance. Its thickness provides strength while remaining easy to bend and shape.

Q: Why choose 3mm galvanised garden wire over regular wire?

A: 3mm galvanised garden wire is coated with zinc, making it weather-resistant and ideal for outdoor use. It withstands moisture and soil exposure, unlike untreated wire that may corrode quickly.

Q: Can 3mm GI wire be used for heavy-duty applications?

A: While 3mm GI (galvanised iron) wire is strong, it’s best suited for medium-duty tasks like trellising or lightweight fencing. For heavier loads, thicker gauges or reinforced materials are recommended.

Q: How does 3mm galvanised wire perform in coastal areas?

A: The zinc coating on 3mm galvanised wire offers moderate protection against saltwater corrosion. For harsh coastal environments, additional anti-rust treatments or stainless steel may be preferable.

Q: Is 3mm galvanised wire safe for securing plants?

A: Yes, 3mm galvanised wire is safe and non-toxic for securing plants, vines, or shrubs. Its smooth surface prevents damage to stems, and the coating ensures long-term outdoor use without degradation.