Understanding 200 Mesh Screens Applications and Benefits

In industries ranging from pharmaceuticals to food processing, the term mesh screen is commonly encountered. One of the most referenced sizes in this domain is the 200 mesh screen. The mesh size indicates the number of openings per inch, determining the particle size that can pass through the screen. A 200 mesh screen, therefore, has 200 openings per linear inch, equating to a particle size passing through of approximately 74 microns. This article will delve into the significance, applications, and benefits of using a 200 mesh screen.

Applications of 200 Mesh Screens

200 mesh screens are versatile tools used in various industries. In the pharmaceutical industry, they play a critical role in ensuring the purity and granulation of active pharmaceutical ingredients (APIs). When processing powders or granules, ensuring that only particles below a certain size are utilized is essential for both efficacy and safety. A 200 mesh screen ensures that larger contaminants are removed, thus maintaining product quality.

In the food processing sector, 200 mesh screens are essential for sifting and separating fine particles in products such as flour, spices, and cocoa powder. This sieve is useful for enhancing texture and ensuring consistency in end products. Additionally, in juice production, 200 mesh screens help in filtering out pulp and seeds, leading to a smoother and more desirable product.

In the chemical industry, these screens are used for pigment and dye processing

. Ensuring that the particles are of the right size can significantly impact the quality and application of these materials. Similarly, in the mining and minerals sector, a 200 mesh screen helps separate fine particles from coarse materials during processing, aiding in more efficient extraction.Benefits of Using 200 Mesh Screens

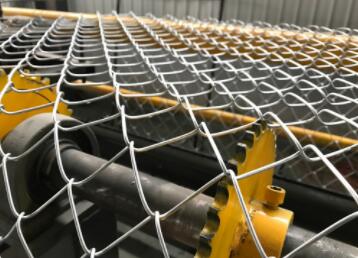

200 mesh screen

One of the primary benefits of using a 200 mesh screen is its ability to deliver precise results. It allows businesses to filter out unwanted particles and achieve consistent product quality. This consistency is not only crucial for compliance with industry standards but also for consumer satisfaction.

Another advantage is the enhanced productivity it offers. By efficiently separating different particle sizes, businesses can reduce the time spent on manual sorting or reprocessing. This increased efficiency can lead to cost savings and better resource management within plants.

Durability and ease of maintenance are additional benefits. Most 200 mesh screens are made from stainless steel or other robust materials that can withstand rigorous handling and prolonged use. Furthermore, cleaning these screens can be done easily, ensuring that cross-contamination is minimized in sensitive applications like food and pharmaceuticals.

Lastly, the versatility of a 200 mesh screen makes it suitable for a wide range of processes, whether wet or dry. This adaptability allows businesses to utilize the same equipment for various tasks, enhancing operational efficiency.

Conclusion

In summary, 200 mesh screens are invaluable tools in various industries. Their ability to filter particles effectively contributes to product quality and consistency while enhancing operational efficiency. As industries continue to strive for perfection in their processes, the role of mesh screens, particularly the 200 mesh size, will undoubtedly remain critical. Whether in pharmaceuticals, food processing, or chemical manufacturing, understanding and utilizing a 200 mesh screen can lead to remarkable improvements in product outcomes.