The Versatility and Importance of Binding Wire in Various Industries

Binding wire, commonly known as binding wire iron, is an essential material that finds its application across a wide range of industries. This thin, flexible wire can typically be made from various metals, with iron being the most prevalent. Its primary purpose is to bind or secure objects together, showcasing both strength and versatility. In this article, we will explore the fascinating characteristics, applications, and importance of binding wire iron in different sectors.

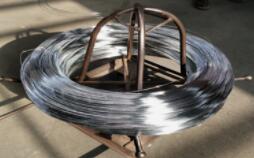

Characteristics of Binding Wire

Binding wire is notable for its malleability and tensile strength, which allows it to be bent and twisted without breaking. This makes it an ideal choice for tasks that require secure fastening while accommodating a degree of flexibility. The wire is often coated or galvanized to prevent rusting, which is particularly important when used in outdoor applications or in environments where moisture is prevalent. The standard diameter of binding wire typically ranges from 0.8 mm to 3.2 mm, offering a variety of options to suit different requirements.

Construction Industry Applications

In the construction industry, binding wire plays a critical role in the reinforcement of structures. It is primarily used to bind rebars (reinforcement bars) together, ensuring a robust framework for concrete structures. This binding process is essential for increasing the tensile strength of concrete and preventing structural failures. Binding wire facilitates the easy assembly of rebar cages and helps in maintaining the integrity of large construction projects, including bridges, buildings, and dams. The wire’s ability to withstand heavy loads while providing flexibility makes it a favorite among contractors and builders.

Agricultural Uses

In the agricultural sector, binding wire is invaluable for various tasks. Farmers utilize it for tying plants and vines, offering support as they grow and maintain proper structural integrity. This is particularly true for climbing plants and vegetables, such as tomatoes and cucumbers, where binding wire helps in training plants to grow vertically, maximizing space and improving yield. Furthermore, binding wire is used for securing bales of hay and straw, making storage and transportation more efficient.

binding wire iron

Manufacturing and Packaging

The manufacturing industry also takes advantage of binding wire iron for packaging and material handling. It is often used to bundle products together for shipment, ensuring that items remain secure during transit. Binding wire’s ability to hold different materials, ranging from metal to plastic, allows manufacturers to maintain an organized inventory and streamline their operations. Additionally, it is commonly used in the production of wire products and other metal works.

Arts and Crafts

Beyond its industrial applications, binding wire is a favorite among artisans and crafters. Its pliability makes it perfect for creating intricate designs and sculptures. Crafters use binding wire to construct jewelry, home décor items, and even garden art. The wire can be manipulated into various shapes and forms, allowing for creative expression without the need for extensive tools or machinery. This artistic application highlights binding wire's versatility beyond traditional industrial uses.

Environmental Considerations

As industries focus more on sustainability, the importance of binding wire in recycling and waste management emerges. Iron binding wire can be recycled, reducing environmental impact and contributing to sustainable practices. Organizations are increasingly utilizing binding wire for packaging recycled materials, promoting a circular economy by giving new life to used products.

Conclusion

Binding wire iron is more than just a common tool; its multifunctionality highlights its importance across various sectors. From construction and agriculture to manufacturing and the arts, binding wire serves as an indispensable resource that underpins many everyday operations. Its resilience, versatility, and ease of use make it a timeless solution that continues to evolve with modern needs. As industries advance toward sustainable solutions, binding wire will likely maintain its relevance, adapting to meet new challenges and opportunities in an ever-changing landscape. Whether in a construction site, a farmer's field, a manufacturing plant, or an artist's studio, binding wire remains a silent yet vital player in the system of industry and creativity.