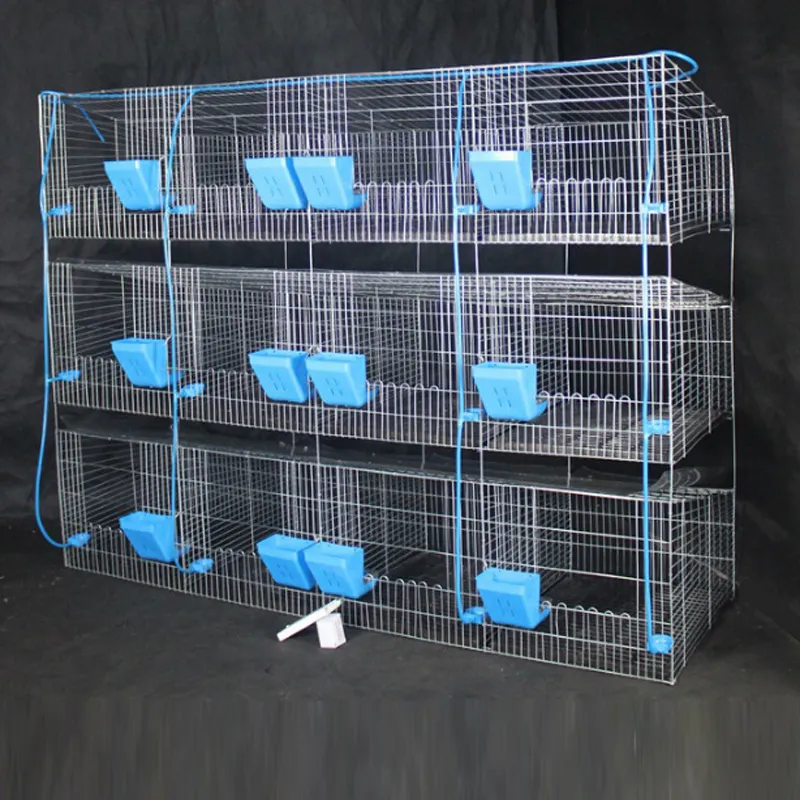

Plastic-coated mesh wire provides a versatile solution for projects requiring a balance of strength and visual appeal, all while ensuring resistance to weather elements. The plastic coating not only enhances the aesthetic value of the wire but also prevents injury from sharp edges, making it a preferred choice for playgrounds, gardens, and residential fencing. The coating can be customized in various colors to seamlessly blend into the environment, adding an extra layer of personalization to projects. Welded wire mesh is another versatile type, noted for its rigidity and structural integrity. It is manufactured by welding perpendicular metal wires at intersections, creating a grid-like structure that is highly stable and strong. This rigidity makes it suitable for creating secure enclosures in industrial settings, including animal cages, partitions, and storage containers. Its ability to maintain shape under heavy loads ensures reliability in demanding applications. Expanded metal mesh differs as it involves cutting and stretching metal sheets to form a diamond-shaped pattern. This process not only strengthens the material but also provides excellent airflow and visibility, making it perfect for applications like security screens, machine guards, and ventilation grilles. The unique pattern adds a modern touch, making it a popular choice for architectural facades where both functionality and aesthetics are desired. In summary, selecting the right type of mesh wire requires a comprehensive understanding of its properties and intended usage. Each variety, from galvanized to expanded metal mesh, serves distinct purposes, offering advantages that cater to industrial, commercial, and decorative needs. Recognizing these elements not only optimizes project outcomes but also leverages the full potential of mesh wires in various applications, reflecting expertise in material selection and project execution. Prioritizing quality and suitability will inevitably foster trust and satisfaction in any professional endeavor involving mesh wire products.