1, galvanized wire mesh molding sheet must be packed with flat hard data, to avoid eternal deformation due to poor packaging.

2, galvanized wire mesh molding sheet storage ground should be flat, according to the symbolic requirements of the accumulation of regular, height should not exceed 2M, and away from heat sources, avoid exposure.

3. The transport, storage and use of the binder of galvanized wire mesh should adopt safety and fire prevention methods according to the relevant regulations, so as to be safer.

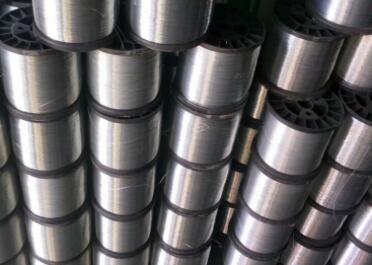

Hot dip galvanized wire 5#-28#, including 500-1000 kg large plate of hot dip galvanized wire. Our hot dip galvanized wire is made of national standard low carbon steel wire after drawing molding, pickling rust removal, high temperature annealing and other processes. The products have the characteristics of strong flexibility, good plasticity and so on. The zinc content can reach 360 g /m2, which is welcomed by customers. We can also provide various specifications of galvanized wire according to customer requirements. The PRODUCTS ARE WIDELY USED IN construction, HIGHWAY fence, TIE-flower, weaving and other industries, mainly used in the manufacture of wire mesh, nail making, highway barrier and construction engineering binding wire, etc.

Post time: 27-07-22