Welcome to the ultimate resource on perforated sheet metal. In an era where efficiency, aesthetics, and performance are paramount, the humble perforated metal sheet has emerged as a critical component across a vast spectrum of industries. Whether you know it as a perforated plate or perforated metal, its applications are bound only by the imagination. This guide offers a deep dive, backed by data and expert insights, into everything you need to know about this remarkable material. We will cover industry trends, technical parameters, manufacturing processes, and real-world case studies, establishing why YJDWireMesh is a trusted leader in this field.

The global market for perforated metal is witnessing significant growth, projected to expand at a CAGR of 5.8% from 2023 to 2030. This growth is driven by the increasing demand for sustainable building materials, advanced filtration systems in the petrochemical sector, and innovative acoustic solutions. A key material in this trend is the perforated aluminum sheet, prized for its lightweight and corrosion-resistant properties, making it ideal for modern architectural projects.

Decoding the DNA: A Guide to Perforated Sheet Technical Parameters

Understanding the technical specifications of a perforated sheet is crucial for selecting the right product for your application. These parameters define the material's functionality, strength, and aesthetic. At YJDWireMesh, we adhere to stringent standards, including those from the Industrial Perforators Association (IPA) and ANSI, to ensure product excellence.

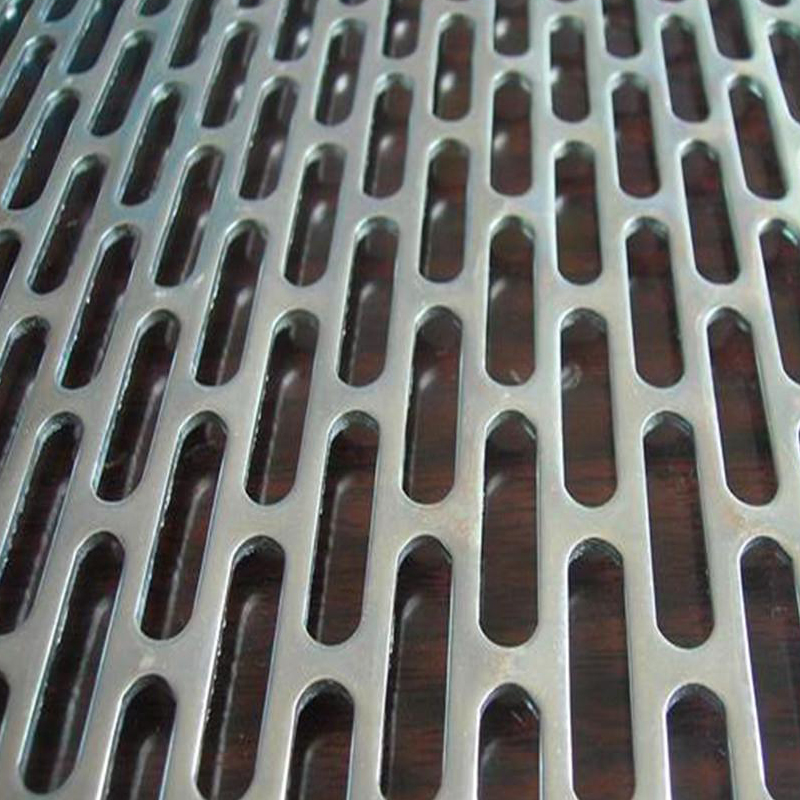

- Hole Pattern: This defines the arrangement of holes. Common patterns include round, square, slotted, and hexagonal. The 60-degree staggered round hole pattern is the most popular due to its high strength and uniform open area.

- Hole Size & Pitch: The hole diameter (or shape dimension) and the distance from the center of one hole to the center of the next (pitch) are critical. These determine the 'open area'.

- Open Area (%): This is the ratio of the total area of the holes to the total area of the sheet, expressed as a percentage. It is a key factor for applications involving airflow, light diffusion, or fluid filtration. It is calculated using specific formulas based on the hole shape and pitch. For example, for 60° staggered round holes: Open Area (%) = (0.907 x (Hole Diameter)²) / (Pitch)² x 100.

- Gauge/Thickness: This refers to the thickness of the metal sheet before perforation. It is a primary determinant of the sheet's strength and durability.

- Material: The choice of material—such as carbon steel, stainless steel (304, 316L), galvanized steel, or a perforated aluminum sheet—depends entirely on the application's requirements for strength, weight, corrosion resistance, and cost.

- Margins & End Patterns: Margins are the unperforated areas along the edges of the sheet. End patterns can be finished with complete or incomplete holes, which can be specified for aesthetic or functional purposes.

Typical Perforated Sheet Specifications (Reference Table)

The following table showcases common configurations for perforated metal sheets. YJDWireMesh offers full customization beyond these examples.

| Material | Thickness (Gauge / mm) | Hole Pattern | Hole Size (Inches / mm) | Pitch (Inches / mm) | Open Area (%) |

|---|---|---|---|---|---|

| Carbon Steel | 16 Ga / 1.5mm | 60° Staggered Round | 0.125" / 3.175mm | 0.1875" / 4.76mm | 40% |

| Stainless Steel 304 | 20 Ga / 0.9mm | Straight Line Square | 0.25" / 6.35mm | 0.375" / 9.525mm | 44% |

| Perforated Aluminum Sheet 5052 | 0.063" / 1.6mm | 60° Staggered Round | 0.25" / 6.35mm | 0.3125" / 7.94mm | 58% |

| Galvanized Steel G90 | 14 Ga / 1.9mm | Slotted | 0.125" x 1" / 3.175mm x 25.4mm | - | Varies |

| Stainless Steel 316L | 11 Ga / 3.0mm | Hexagonal | 0.5" / 12.7mm | 0.5625" / 14.29mm | 79% |

From Raw Coil to Finished Product: The Perforated Mesh Manufacturing Process

The creation of a high-quality perforated sheet is a precise, multi-stage process that blends heavy machinery with meticulous quality control. At YJDWireMesh, our ISO 9001:2015 certified process ensures every perforated plate we produce meets the highest standards of quality and durability.

1. Material Selection

2. Die & Tooling Setup

3. CNC Perforation

4. Leveling & Finishing

5. Quality Inspection

6. Packaging

- Step 1: Raw Material Selection & Verification: The process begins with sourcing premium metal coils or sheets (e.g., aluminum, stainless steel, carbon steel). We conduct material composition analysis to verify grade and compliance with standards like ASTM A1011 (Steel) or ASTM B209 (Aluminum).

- Step 2: Die & Tooling Setup: For stamping processes, a specific die set matching the desired hole pattern, size, and pitch is mounted onto a high-speed press. For more complex or custom designs, a CNC laser cutter or turret punch press is programmed.

- Step 3: Perforation: The metal sheet is fed through the press. For a perforated metal sheet, the press can make hundreds or thousands of punches per minute. This process must be carefully controlled to prevent distortion. CNC processes offer higher precision for custom or short-run jobs.

- Step 4: Leveling, Degreasing, and Finishing: The perforation process can induce stress and slight curvature in the sheet. It is passed through a leveling machine to ensure perfect flatness. Afterward, the sheets are cleaned and degreased. Optional finishing processes like powder coating, anodizing (especially for perforated aluminum sheet), or galvanizing are applied for enhanced corrosion resistance and aesthetics.

- Step 5: Quality Inspection (ISO 9001): Every batch undergoes rigorous inspection. We check hole size and shape accuracy, pitch, thickness, flatness, and surface finish against the customer's specifications and international standards. This is a critical step to demonstrate our trustworthiness.

- Step 6: Packaging & Logistics: Finished sheets are carefully packaged on pallets with protective layers to prevent scratches or damage during transit, ensuring they arrive at the customer's site in perfect condition.

Performance Metrics: Visualizing Perforated Metal Advantages

Data visualization helps clarify the key benefits of different perforated materials. The choice between a robust steel perforated plate and a lightweight perforated aluminum sheet often comes down to a trade-off between strength, weight, and cost. Below, we illustrate these comparisons.

As the charts demonstrate, while carbon steel offers maximum strength, its weight is a significant factor. In contrast, perforated aluminum sheet provides an excellent strength-to-weight ratio, making it the preferred choice for applications where weight is a critical design constraint, such as aerospace, transportation, and architectural facades.

The YJDWireMesh Advantage: Expertise & Trustworthiness

Choosing a supplier for a critical component like a perforated sheet is a major decision. It's not just about the product; it's about partnership, reliability, and expertise. Here’s how YJDWireMesh stands apart from generic suppliers.

| Feature | YJDWireMesh | Generic Competitor |

|---|---|---|

| Customization | Fully customizable hole shapes, patterns, materials, and finishes. In-house engineering support. | Limited to standard stock sizes and patterns. |

| Material Grades | Certified materials (e.g., 316L, 5052-H32) with Mill Test Certificates (MTCs) provided. | Unspecified or non-certified material sources. |

| Certifications | ISO 9001:2015 Certified Quality Management System. | No formal certification. |

| Lead Time | Transparent and reliable lead times, with expedited options available. | Variable and often unreliable delivery schedules. |

| Technical Support | Dedicated engineers to assist with design, material selection, and open area calculations. | Basic sales support only. |

| Performance Testing | Can provide data from salt spray tests (ASTM B117), load-bearing tests, and acoustic performance tests. | No performance data available. |

Tailored Solutions: Customizing Your Perforated Metal Sheet

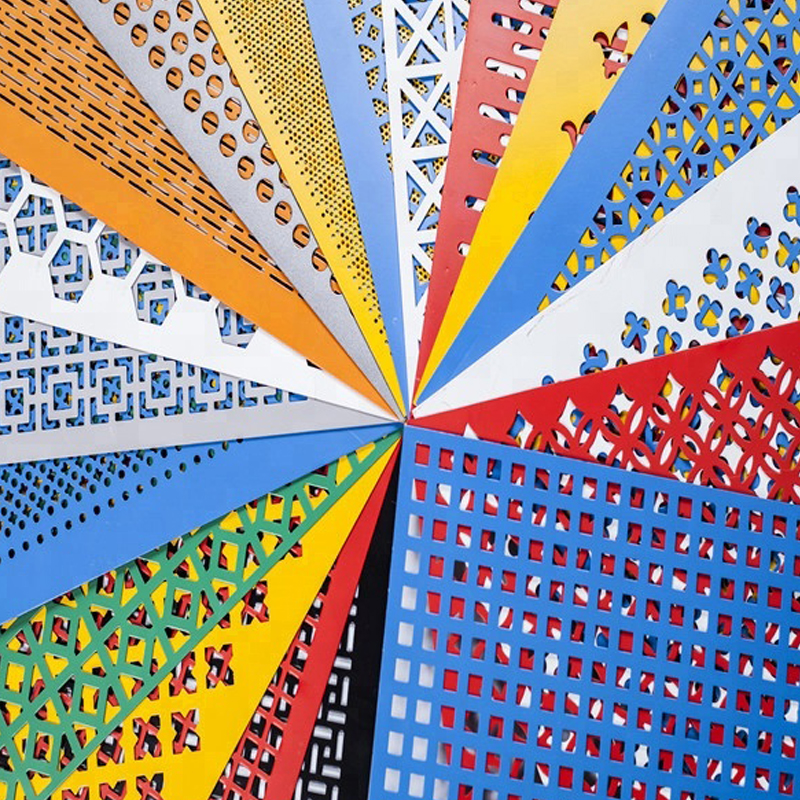

One of the greatest strengths of perforated sheet is its adaptability. At YJDWireMesh, we specialize in transforming your vision into reality. Our customization capabilities extend far beyond standard options:

- Unique Hole Shapes and Patterns: From corporate logos to artistic geometric designs, our CNC machinery can create nearly any pattern imaginable.

- Variable Perforation: We can create gradients of perforation, with hole sizes or spacing changing across the sheet for functional or aesthetic effects.

- Specialized Finishes: Beyond standard powder coating and anodizing, we offer PVDF coatings for extreme durability, anti-graffiti coatings, and custom color matching.

- Forming and Fabrication: We don't just supply flat sheets. We can roll, bend, weld, and frame your perforated metal to create ready-to-install components like column covers, infill panels, or ventilation grilles.

Application in Action: Real-World Case Studies (Experience & Expertise)

The true value of a perforated metal plate is proven in its application. Here are some examples of how our products have provided solutions for our clients.

Architectural Facade: The 'Urban Bloom' Tower

Challenge: An architectural firm needed a dynamic building facade that provided sun shading without obstructing views, all while being lightweight to reduce structural load.

Solution: We provided custom-patterned perforated aluminum sheets (Grade 5052-H32) with a durable PVDF finish. The variable open area design was optimized using thermal modeling.

Result: 35% Reduction in Solar Heat Gain The building's cooling costs were significantly lowered, contributing to its LEED Gold certification. The facade became an iconic design feature.

Industrial Filtration: Petrochemical Processing Plant

Challenge: A major petrochemical client was experiencing premature failure of their catalyst support screens due to high temperatures and corrosive materials.

Solution: We fabricated a heavy-duty perforated plate from 316L Stainless Steel, known for its superior corrosion resistance. The holes were deburred to ensure smooth flow and prevent catalyst damage.

Result: 200% Increase in Service Life The new perforated plates extended the maintenance cycle from 6 months to over 18 months, saving millions in downtime and replacement costs.

Acoustic Control: University Lecture Hall

Challenge: A new university lecture hall suffered from poor acoustics, with excessive echo and reverberation affecting speech intelligibility.

Solution: We supplied micro-perforated metal ceiling and wall panels. These panels, combined with an acoustic backing, absorb sound waves effectively.

Result: 60% Reduction in Reverberation Time The hall's acoustics were transformed, achieving an excellent Noise Reduction Coefficient (NRC) rating and creating a superior learning environment.

Your Partner in Quality: Trust & Assurance Guarantees

Our commitment to you extends beyond the factory floor. We build trust through transparency, quality, and unwavering support.

ISO 9001 Certified

Our manufacturing processes are rigorously audited and certified, ensuring consistent quality and continuous improvement.

Transparent Delivery

We provide clear, reliable delivery timelines and proactive communication, so you can plan your project with confidence. Typical lead times for standard products are 2-3 weeks.

Solid Warranty

We stand by our products with a comprehensive warranty covering material defects and manufacturing flaws, giving you complete peace of mind.

Frequently Asked Questions (FAQ)

1. What is the difference between pitch and open area on a perforated sheet?

Pitch is the physical measurement of the distance from the center of one hole to the center of the adjacent hole. Open Area is a calculated percentage that represents the total area of the holes relative to the total area of the sheet. While related, they are not the same. A larger pitch with the same size hole will result in a smaller open area. The open area is the critical factor for applications requiring ventilation or filtration.

2. How do I choose the right material for my perforated metal sheet?

The choice depends on four key factors: Environment (corrosion risk), Strength (load-bearing requirements), Weight (is it a mobile or overhead application?), and Budget.

- For outdoor/corrosive environments: Use Stainless Steel (304/316L) or a perforated aluminum sheet.

- For high strength and low cost: Carbon Steel is best, but may require coating.

- For lightweight applications: Aluminum is the premier choice.

3. What does 'gauge' (Ga) mean in relation to a perforated metal sheet?

Gauge (Ga) is a standardized measurement of a sheet's thickness. It's important to note that for most metals, a lower gauge number means a thicker, stronger sheet. For example, 11 gauge (approx. 3mm) steel is much thicker and more robust than 20 gauge (approx. 0.9mm) steel. Always verify the actual thickness in millimeters or inches to avoid confusion between different gauge systems (e.g., for steel vs. aluminum).

4. Can you create custom hole patterns not listed in your catalog?

Absolutely. This is one of our core strengths. Using our advanced CNC turret punches and laser cutters, we can create custom patterns from your CAD files (e.g., .DXF or .DWG). This is ideal for branding, architectural features, or unique functional requirements. We can perforate logos, artistic designs, and non-standard geometric shapes into a perforated sheet.

5. What are the standard manufacturing tolerances for a perforated plate?

We adhere to the standards set by the Industrial Perforators Association (IPA). Typical tolerances include +/- on hole size, pitch, and overall sheet dimensions. For example, a standard tolerance for sheet width/length might be +/- 1.5mm. However, for applications requiring higher precision, we can achieve much tighter tolerances upon request. It's crucial to discuss these requirements during the quoting process.

6. What finishing options are available and why would I choose one?

Finishes enhance both aesthetics and durability.

- Powder Coating: Offers a durable, colorful, and uniform finish. Excellent for most architectural and decorative applications.

- Anodizing: An electrochemical process for aluminum that creates a very hard, corrosion-resistant surface. Ideal for a perforated aluminum sheet in harsh environments.

- Galvanizing: A zinc coating applied to steel to prevent rust. Best for industrial or outdoor applications where cost is a primary concern.

- PVDF Coating: A premium finish with exceptional resistance to weathering, UV rays, and chemicals. Used for high-end curtain walls and facades.

7. How is the strength of a perforated plate affected by the perforation?

Perforation naturally reduces the strength of the original solid sheet. The amount of strength reduction is directly related to the open area and the pattern. A higher open area results in lower strength. However, the 60-degree staggered pattern provides the highest strength for a given open area because it distributes stress more evenly than a straight-line pattern. For structural applications, our engineers can perform calculations or Finite Element Analysis (FEA) to ensure the specified perforated plate will meet the required load-bearing capacity.

Conclusion & Further Reading

The versatility of the perforated sheet makes it an indispensable material for modern engineering and design. From the robust utility of an industrial perforated plate to the sleek aesthetics of a perforated aluminum sheet facade, the possibilities are endless. By understanding the key technical parameters, manufacturing processes, and material advantages, you can make informed decisions that enhance your project's performance, longevity, and value.

YJDWireMesh is more than a supplier; we are your partner in innovation. Contact us today to discuss your project and discover how our expertise in perforated metal can bring your concept to life.

Authoritative References:

- Industrial Perforators Association (IPA). (n.d.). Standards & Tolerances. Retrieved from their official industry publications.

- "The Hole Story on Perforated Metals." The Fabricator, FMA Communications, Inc. https://www.thefabricator.com/thefabricator/article/metalsmaterials/the-hole-story-on-perforated-metals

- "Designing with Perforated Metal for Facades and More." Metalforming Magazine. https://www.metalformingmagazine.com (general reference to industry publication).