Round Perforated Steel Sheets Versatile Solutions for Modern Applications

Round perforated steel sheets have become an essential material in various industries due to their unique properties and versatility. These sheets are made by punching holes into steel sheets, creating patterns that can be customized according to specific needs. The round holes add aesthetic appeal and functionality, making them suitable for numerous applications in architecture, manufacturing, filtration, and more.

One of the key advantages of round perforated steel sheets is their lightweight yet durable nature. Despite being composed of metal, the perforations reduce the overall weight without compromising strength. This characteristic makes them ideal for projects where structural integrity and weight savings are crucial, such as in the construction of facades, ceilings, and walls. Furthermore, the holes can be strategically placed to enhance airflow and reduce wind resistance, which is particularly beneficial in architectural designs.

In industrial settings, these sheets are often used for filtration purposes. The size and spacing of the perforated holes can be customized to meet specific filtration requirements, making them suitable for applications ranging from water treatment to air filtration. Round perforated sheets help ensure optimal flow rates while effectively trapping unwanted particles, contributing to cleaner environments.

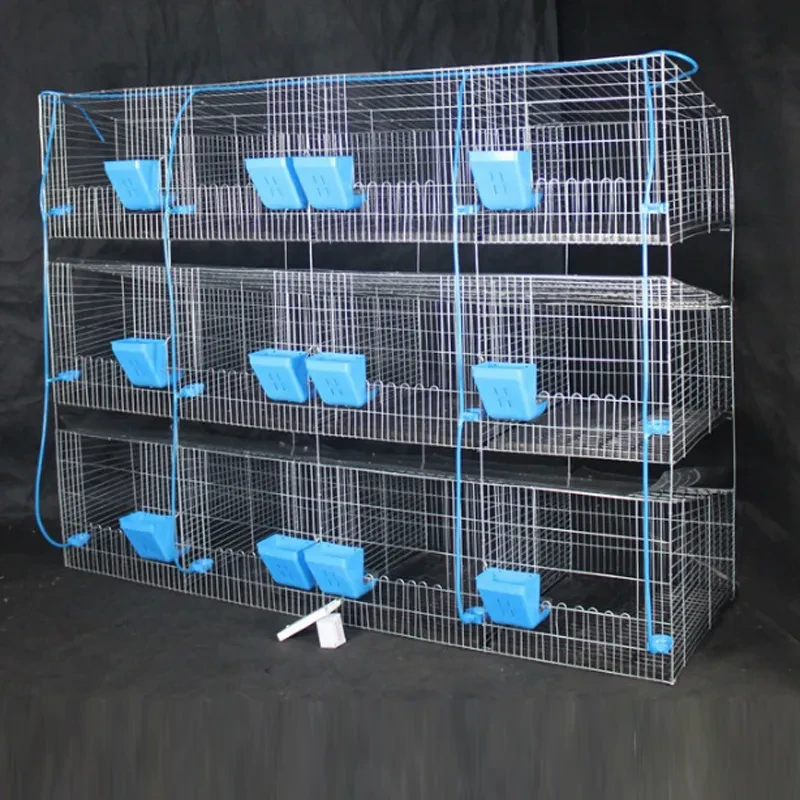

round perforated steel sheet

Moreover, their aesthetic value cannot be overlooked. Designers and architects frequently utilize round perforated steel sheets to create visually striking elements in buildings. The interplay of light and shadow that results from the perforated patterns can enhance the visual appeal of both interior and exterior spaces. Whether used as decorative partitions, facades, or roofing elements, these sheets allow for creative expression while providing functionality.

In terms of maintenance, round perforated steel sheets are relatively easy to care for. Most modern coatings and finishes enhance their resistance to corrosion, ensuring that they maintain their appearance and structural integrity over time. This durability makes them a cost-effective choice, as they require less frequent replacement or repair compared to other materials.

The manufacturing process of round perforated steel sheets has also seen advancements, leading to increased efficiency and precision. Modern techniques such as laser cutting and CNC machining allow for more intricate designs and tighter tolerances, catering to the evolving needs of various industries. As technology continues to advance, the applications for round perforated steel sheets are likely to expand even further.

In conclusion, round perforated steel sheets stand out as a versatile solution for a multitude of applications. Their blend of strength, aesthetic versatility, and functionality makes them an invaluable component in many sectors, from construction and industrial processes to artistic installations. As we move forward, the demand for innovative and sustainable materials like round perforated steel sheets is expected to grow, solidifying their role in modern design and manufacturing.