Understanding Wire Mesh Gauge and Its Measurement in Millimeters

Wire mesh is a versatile material used in various applications, including construction, agriculture, and industry. One fundamental aspect of wire mesh is its gauge, which indicates the wire's thickness. Understanding wire mesh gauge and how it translates into millimeters (mm) is essential for choosing the right type of mesh for your specific needs.

What is Wire Mesh Gauge?

Wire mesh gauge refers to the standardized measurement used to denote the diameter of the wire that makes up the mesh. The gauge system can vary by country, with some regions using the American Wire Gauge (AWG) or the British Standard Wire Gauge (SWG). The gauge number inversely correlates with the wire diameter a higher gauge number corresponds to a thinner wire, while a lower gauge number indicates a thicker wire. For instance, a wire mesh gauge of 10 indicates a thicker wire than a mesh gauge of 20.

Converting Wire Gauge to Millimeters

To effectively utilize wire mesh, it is crucial to convert the gauge measurement into a more universally understood metric unit, such as millimeters. This conversion is indicative of the wire’s diameter, crucial for determining the mesh's strength, durability, and appropriate application.

In general, the conversion can be done using standard charts that provide the equivalent values of wire gauges in millimeters. For example, in the AWG system - A gauge of 10 typically translates to approximately 2.588 mm. - A gauge of 12 converts to around 2.053 mm. - A gauge of 14 equates to approximately 1.628 mm. - A gauge of 16 corresponds to about 1.291 mm. - A gauge of 18 equals roughly 1.024 mm. - Higher gauges such as 20 and 22 return lower measurements of about 0.812 mm and 0.644 mm, respectively.

Importance of Choosing the Right Wire Gauge

wire mesh gauge to mm

Choosing the appropriate wire mesh gauge is vital depending on the application. For instance, in construction and fencing, a thicker wire (lower gauge number) is often preferable for greater strength and resistance to deformation. Conversely, in applications like animal cages or household screens, a thinner wire may suffice while providing adequate safety and protection.

The wire gauge also impacts the mesh's openness, or the size of the holes formed by the woven wires. Thicker wires create slightly larger openings, which can be a consideration for applications needing specific levels of airflow or light penetration. Hence, selecting the correct wire gauge ensures that you achieve the desired balance between strength and functionality.

Applications of Wire Mesh

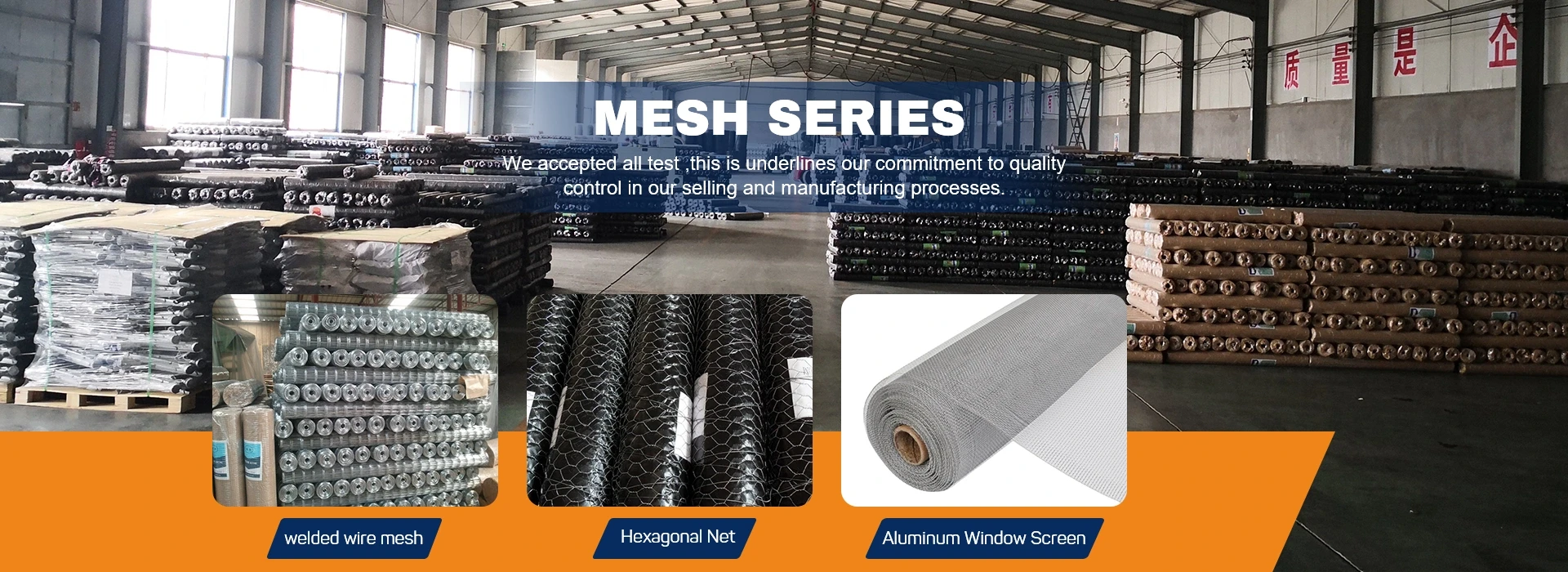

Wire mesh has an array of applications across numerous industries. In construction, it is often used for reinforcement in concrete structures. In agriculture, wire mesh is employed for fencing livestock, protecting crops, and creating animal enclosures. In industrial sectors, wire mesh is utilized in products like filters and sieves, contributing to various manufacturing processes.

Due to its versatility, wire mesh can also be adapted for unique applications, leading to various custom specifications. Knowing the wire gauge and its equivalent in millimeters is crucial during this customization process.

Conclusion

Wire mesh gauge is a fundamental measurement that impacts the mesh's application and effectiveness. By understanding how to convert wire gauge to millimeters, users can make informed decisions when selecting wire mesh for various purposes. Whether for construction, agriculture, or industrial uses, recognizing the appropriate gauge ensures that the right mesh is selected for optimal performance and durability. Therefore, it is essential to utilize resources and conversion charts effectively to choose the right wire mesh for your needs.