Understanding Wire Screen Prices Factors Influencing Cost and Market Trends

Wire screens play a vital role in various industries, serving as essential components in filtration, separation, and screening processes. From construction and mining to food processing and water treatment, wire screens are ubiquitous. However, understanding the factors that influence their prices is crucial for businesses and individuals looking to invest in these essential materials.

What is a Wire Screen?

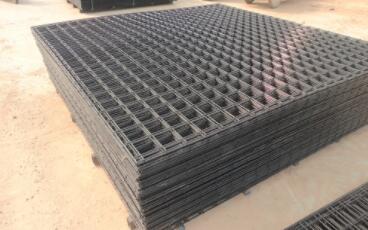

A wire screen, often referred to as wire mesh or wire cloth, is made from woven or welded metal wires of various diameters and materials. The configuration and material of the wire determine its application and performance. Common materials include stainless steel, carbon steel, brass, and aluminum, each offering unique properties that affect the screen's durability, flexibility, and resistance to corrosion.

Factors Influencing Wire Screen Prices

1. Material Composition The type of material used in the production of wire screens significantly influences its price. Stainless steel, for instance, is more expensive than carbon steel due to its superior corrosion resistance and strength. Specialty alloys or treated materials also come at a premium, reflecting the added value in terms of durability and longevity.

2. Wire Diameter and Mesh Size The thickness of the wires and the mesh size (the number of openings per unit length) are crucial in determining the cost. Generally, finer mesh sizes and thicker wires lead to increased production costs, as they require more material and more intricate manufacturing processes. For specific applications such as filtration in high-pressure environments, the demand for reinforced screens can further escalate prices.

3. Manufacturing Process The method of production, whether woven or welded, impacts the cost of wire screens. Welding processes, which provide greater strength and stability, typically are more labor-intensive and costly than weaving methods. Automated production techniques can reduce costs but might still involve significant upfront investment in machinery.

wire screen price

4. Customization and Specifications Custom wire screens tailored to specific dimensions or requirements can be considerably more expensive than standard options. Factors such as non-standard sizes, particular coatings (like galvanization for corrosion resistance), and additional treatments (for enhanced performance) all contribute to the total price.

5. Market Demand and Supply Like any commodity, the market dynamics of supply and demand can significantly affect wire screen prices. Fluctuations in demand from industries like construction, mining, and food processing can lead to price increases during peak usage periods. Conversely, surplus production can result in lower prices.

6. Geographic Factors The source of materials and logistic costs also impact pricing. Importing wire screens from countries with low labor costs can be cheaper, but tariffs and shipping expenses can negate those savings. Local manufacturing might command higher prices due to labor and operational costs but often allows for quicker delivery times and reduced shipping expenses.

Current Market Trends

As of late 2023, the wire screen market has shown fluctuations in pricing, largely influenced by global economic conditions, rising raw material costs, and labor shortages in some regions. The recovery from the COVID-19 pandemic led to increased construction activities and material shortages, pushing prices higher. Moreover, advancements in manufacturing technology are enabling producers to create more sophisticated wire products, which can influence both the performance and pricing structures in the market.

Additionally, there is a growing trend towards sustainable manufacturing practices in the wire screen industry. Companies are investing in environmentally friendly materials and processes, which can lead to higher initial costs but may provide long-term savings and market advantages due to an increasing demand for eco-friendly products.

Conclusion

Understanding the various factors influencing wire screen prices is essential for anyone involved in industries dependent on these products. By considering aspects such as material composition, manufacturing processes, and market dynamics, businesses can make informed purchasing decisions. As the industry evolves with technological advancements and shifts in consumer demand, staying informed about these trends is critical for ensuring both quality and value in wire screen procurement. Whether you are a buyer in construction, filtration, or agriculture, being aware of these nuances can help you navigate the complexities of wire screen pricing effectively.