The Versatility of Galvanized Straining Wire in Modern Applications

Galvanized straining wire is an indispensable component in various industries due to its strength, durability, and resistance to corrosion. Primarily made of high tensile steel, this wire is coated in a layer of zinc to protect it from the elements, making it an ideal choice for outdoor applications and environments where moisture is a concern. In this article, we will explore the various uses of galvanized straining wire, the benefits it offers, and the factors to consider when selecting the right type for your project.

One of the most common applications of galvanized straining wire is in fencing. Whether for agricultural purposes or residential properties, this wire is crucial for the support and stability of fencing systems. It is often used to create tension in wire fences, ensuring that they remain taut and effective in containing livestock or providing necessary security measures. The galvanized coating prevents rust, allowing these fences to withstand the test of time, even in harsh weather conditions.

In addition to fencing, galvanized straining wire is widely utilized in construction and building projects. It serves as a reliable means for securing and stabilizing structures, particularly in the setting up of scaffolding and other temporary support systems. Builders appreciate its high tensile strength, which allows it to bear heavy loads while maintaining structural integrity. The zinc coating ensures that the wire does not succumb to rust, which could compromise the strength of the scaffolding over time.

Moreover, this type of wire can be found in the horticulture industry. It is frequently used in the training and supporting of plants, such as vines and fruit trees. Gardeners and landscapers use galvanized straining wire to create trellises and support systems that promote healthy growth and fruit production. The durability of the galvanized coating means that this support will last for many seasons, allowing plants to thrive without the need for frequent replacements.

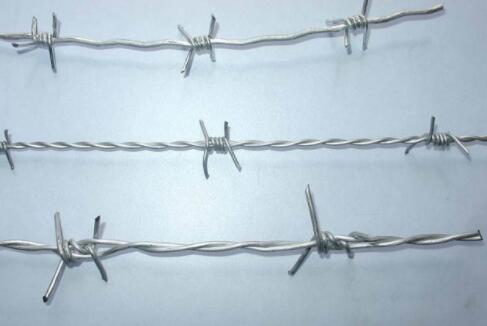

galvanized straining wire

The versatility of galvanized straining wire extends to various industrial applications as well. It is commonly used in manufacturing processes, especially in the production of wire ropes and cables. Its corrosion-resistant properties make it suitable for use in marine environments, where exposure to saltwater could hasten the deterioration of other materials. Additionally, the strength of the wire makes it an ideal choice for cranes and heavy lifting equipment, ensuring safety and reliability in heavy-duty operations.

When selecting galvanized straining wire, several factors must be considered to ensure that you choose the correct product for your needs. The diameter of the wire is one of the most critical aspects, as it directly affects the wire's strength and suitability for various applications. Thicker wires generally offer greater tensile strength, making them ideal for more demanding tasks. Conversely, thinner wires may be suitable for lighter-duty applications, such as garden trellises.

In addition to diameter, it is essential to consider the gauge of the wire. A lower gauge number indicates a thicker wire, while a higher number signifies a thinner wire. Understanding the appropriate gauge for your specific application is vital to achieve the desired outcome, whether you require a robust support system for building projects or a more delicate structure for plant support.

In conclusion, galvanized straining wire is a versatile and practical solution across numerous industries. Its strength, durability, and resistance to corrosion make it an ideal choice for applications ranging from fencing to construction and horticulture. When selecting the right type of wire for your project, consider factors such as diameter and gauge to ensure optimal performance and longevity. Whether you are a farmer, builder, or gardener, incorporating galvanized straining wire into your toolkit can significantly enhance your work and improve the results of your projects.